Carbon nanotube grafted hydroxyl-terminated polyurethane electrophoretic resin and cathodic polyurethane electrophoretic paint, and preparation methods thereof

A technology of hydroxyl-terminated polyurethane and carbon nanotubes, which is applied in the direction of electrophoretic coatings, conductive coatings, coatings, etc., can solve the problems of easy aggregation of carbon nanotubes, achieve environmental friendliness, reduce sedimentation, and improve mechanical properties and functionality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a method for preparing the carbon nanotube grafted hydroxyl polyurethane electrophoretic resin as described in the above embodiments, comprising the following steps:

[0040] S1: Vacuum-dry hydroxyl carbon nanotubes at 100-120°C, then mix with toluene diisocyanate, ultrasonically react at 60-80°C, and then centrifuge at high speed to obtain oil-soluble isocyanate groups. Activated carbon nanotubes are dissolved in isophorone diisocyanate and mixed uniformly to obtain a mixture of isocyanate-modified carbon nanotubes and isophorone diisocyanate;

[0041]In this step, the hydroxyl carbon nanotubes are dried first, the main purpose is to remove the adsorbed water due to hydrogen bonding. In order to dry fully, the drying time can be 2-3 hours, which can be adjusted according to the actual situation. Then, toluene diisocyanate is used to modify the hydroxyl carbon nanotubes to prepare isocyanate group reaction-modified carbon nanotubes. ...

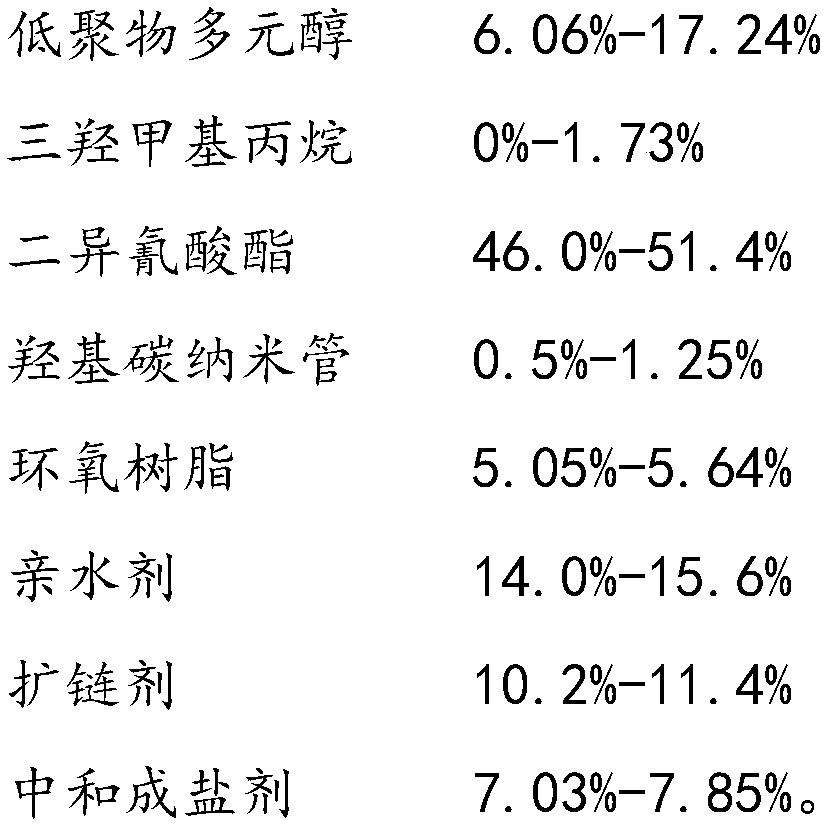

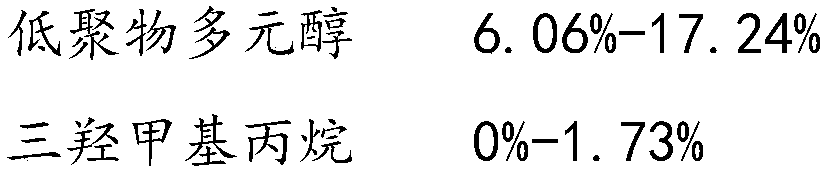

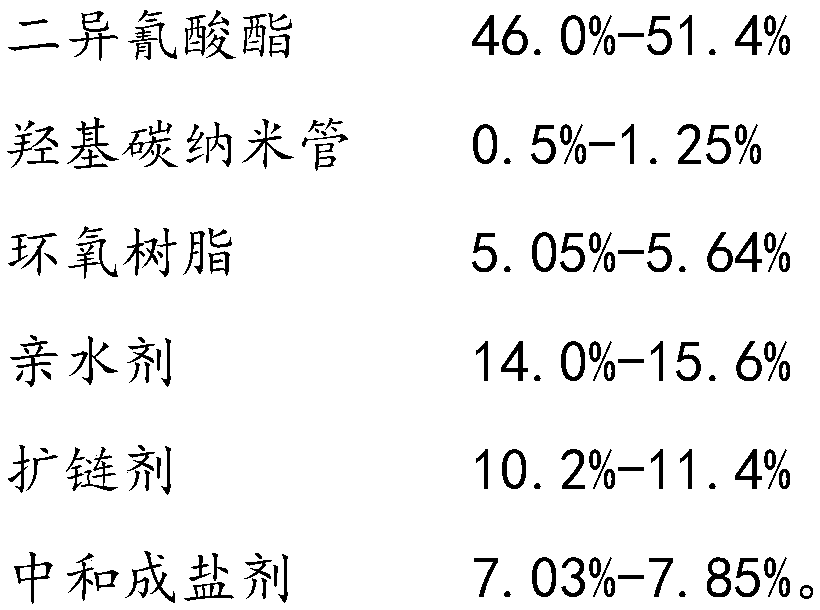

Embodiment 1

[0055] Take 11.1g of polycarbonate diol and 1.0g of trimethylolpropane, and dehydrate at 90°C for 1h; take 44.7g of a mixture containing 0.3g of isocyanate-modified carbon nanotubes and isophorone diisocyanate and add In the reaction of the previous step, react at 80°C for 2h; then add 13.5g of N-methyldiethanolamine in the presence of solvent 1,4-dioxane, and react at 40°C for 2h; , in the presence of 4-dioxane, add 4.8g epoxy resin and 9.8g neopentyl glycol, chain extension reaction at 80°C for 2h; finally cool down to 30°C, add 6.8g glacial acetic acid, 6g n-butanol and 12g Ethylene glycol butyl ether was neutralized for 1 hour to obtain carbon nanotube grafted hydroxyl polyurethane electrophoresis resin.

[0056] Take 48g of the above-mentioned carbon nanotube grafted hydroxyl polyurethane electrophoresis resin again, add 11.1g cationic water dispersible blocked type isocyanate and 1.4g propylene glycol phenyl ether to it, after emulsifying and shearing in water, form a fi...

Embodiment 2

[0058] Take 13.9g of polycarbonate diol and 1.2g of trimethylolpropane, and carry out dehydration treatment at 90°C for 1h; take 55.9g of a mixture containing 0.75g of isocyanate-modified carbon nanotubes and isophorone diisocyanate and add In the reaction of the previous step, react at 80°C for 2h; then add 16.9g of N-methyldiethanolamine in the presence of solvent 1,4-dioxane, and react at 40°C for 2h; , in the presence of 4-dioxane, add 6.1g epoxy resin and 12.3g neopentyl glycol, chain extension reaction at 80°C for 2h; finally cool down to 30°C, add 8.5g glacial acetic acid, 7.5g n-butanol and 15 g of ethylene glycol butyl ether was neutralized for 1 h to obtain a carbon nanotube grafted hydroxyl polyurethane electrophoresis resin.

[0059] Get 60g of the above-mentioned carbon nanotube grafted hydroxyl polyurethane electrophoretic resin again, add 14.13g cationic water dispersible blocked type isocyanate and 1.8g propylene glycol phenyl ether to it, after emulsifying and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| acid resistance | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com