Method for environmentally-friendly treatment and recycling of cyanide barren solution

A treatment cycle and environmental protection technology, applied in the direction of improving process efficiency, etc., can solve the problems of low concentration of lye, hydrogen cyanide pollution, environmental pollution and other problems, to improve the recovery rate of cyanide, increase zinc concentrate products, The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

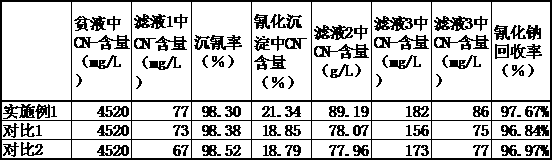

Embodiment 1

[0032] 1) Cyanide sinking operation: the total cyanide content in the cyanide-containing barren solution is 4526mg / L, and the gold content is 0.02g / m 3 , the silver content is 0.05g / m 3 , with a copper content of 0.862g / L and a zinc content of 1.42g / L, add zinc chloride and stir for 0.5-1 hour, during which the pH is controlled at 7.6-8.2. The ore pulp was precipitated in the sedimentation tower for 2 hours, and the precipitate was filtered into cyanide filter cake and filtrate 1.

[0033] 2) Cyanide precipitation conversion: add water 1.5 times the weight of the cyanide filter cake into the stirring tank, start stirring, add the cyanide filter cake into the stirring tank, slowly add sodium carbonate, control the pH value to 11, and stir for 1.5 hours . The pulp is filtered and washed to obtain filtrate 2 and carbonic acid slag.

[0034] 3) Acidification of carbonic acid slag filter cake: Carbonic slag and water are added into the closed stirring tank according to the mass ...

Embodiment 2

[0039] 1) Cyanide sinking operation: the total cyanide content in the cyanide-containing barren solution is 4526mg / L, and the gold content is 0.02g / m 3 , the silver content is 0.05g / m 3 , with a copper content of 0.862g / L and a zinc content of 1.42g / L, add zinc sulfate and stir for 0.5-1 hour, during which the pH is controlled at 7.6-8.2. The ore pulp was precipitated in the sedimentation tower for 2 hours, and the precipitate was filtered into cyanide filter cake and filtrate 1.

[0040] 2) Cyanide precipitation conversion: cyanide filter cake is added to the stirring tank at a weight ratio of 30%, the pulp temperature is controlled at 30°C, sodium carbonate is slowly added, and the pH value is controlled at 11, and stirred for 1.5 hours. The pulp is filtered and washed to obtain filtrate 2 and carbonic acid slag.

[0041] 3) Acidification of carbonic acid slag filter cake: Carbonic slag and water are added into the closed stirring tank according to the mass ratio of 20:80,...

Embodiment 3

[0046] 1) Cyanide sinking operation: the total cyanide content in the cyanide-containing barren solution is 4526mg / L, and the gold content is 0.02g / m 3 , the silver content is 0.05g / m 3 , with a copper content of 0.862g / L and a zinc content of 1.42g / L, add zinc chloride and stir for 0.5-1 hour, during which the pH is controlled at 7.6-8.2. The ore pulp was precipitated in the sedimentation tower for 2 hours, and the precipitate was filtered into cyanide filter cake and filtrate 1.

[0047] 2) Cyanide precipitation conversion: cyanide filter cake is added to the stirring tank at a weight ratio of 30%, the slurry temperature is controlled at 30°C, potassium carbonate is slowly added, and the pH value is controlled at 11, and stirred for 1.5 hours. The pulp is filtered and washed to obtain filtrate 2 and carbonic acid slag.

[0048] 3) Acidification of carbonic acid slag filter cake: add 30% weight ratio of carbonic acid slag filter cake into the closed stirring tank, slowly ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com