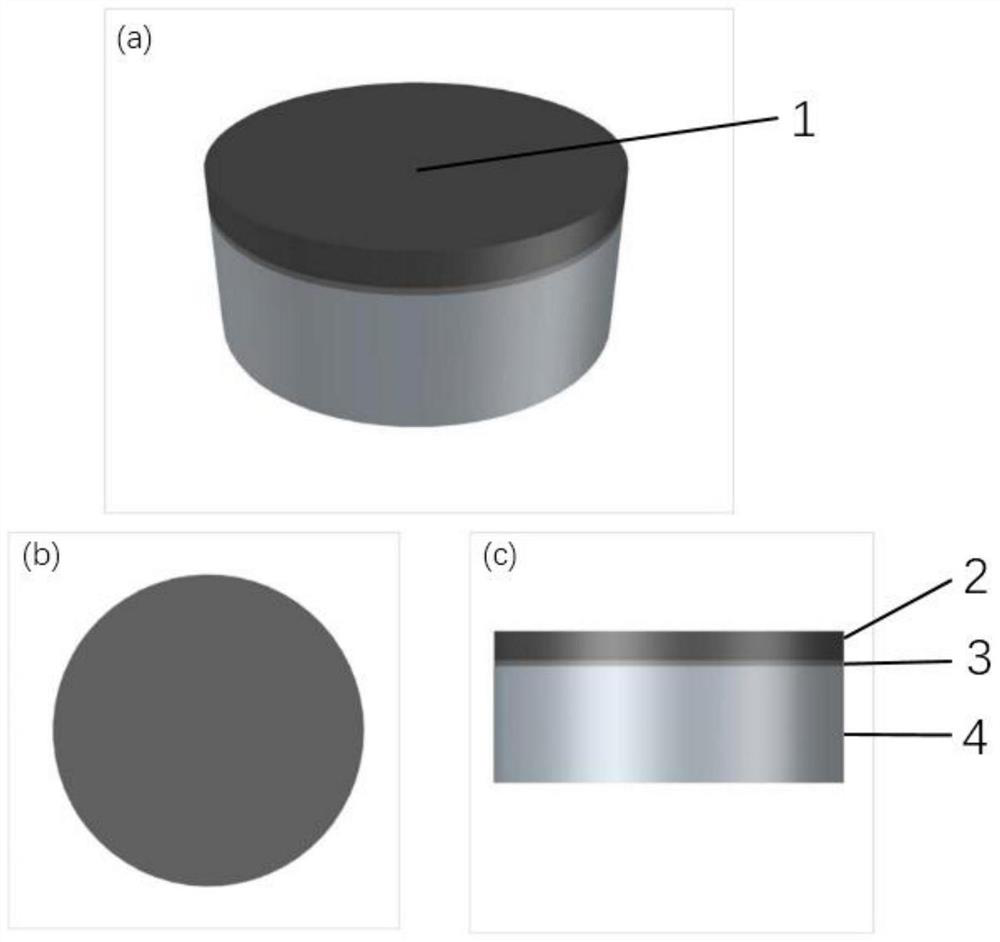

A kind of scandium-containing cathode on the top layer of submicron structure and preparation method thereof

A submicron and cathode technology, which is applied in the manufacture of cold cathodes, thermionic cathodes, and electrode systems, can solve the problems of uneven diffusion and distribution of scandium and its oxides, shorten the preparation time, etc., and achieve high emission performance, emission good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

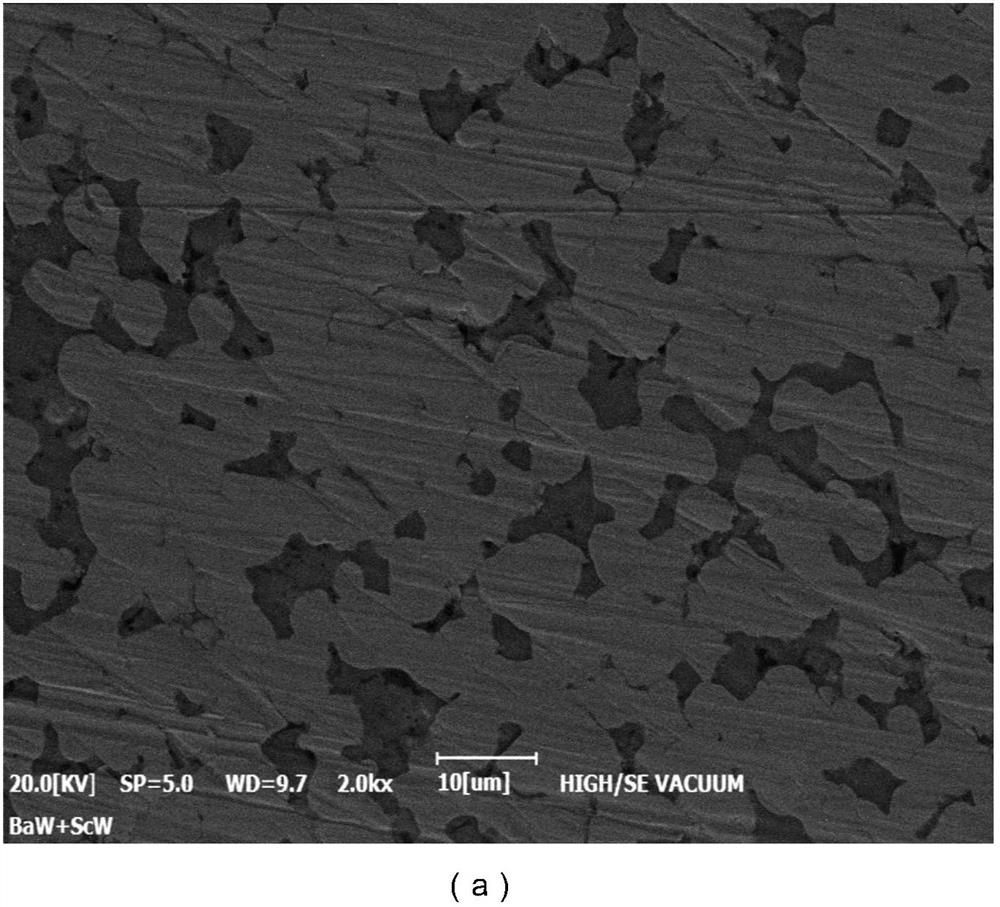

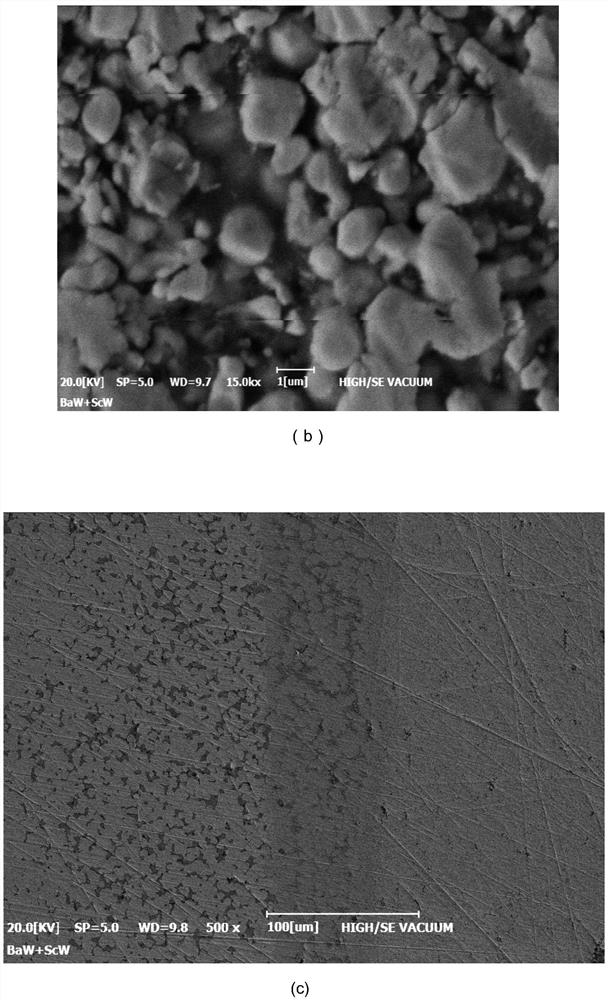

Embodiment 1

[0026] Example 1 Dissolve 127.1g of ammonium metatungstate, 16.8g of scandium nitrate, and 143.9g of citric acid in deionized water, mix well after stirring, put the mixed solution into a water bath and heat to obtain a light yellow xerogel. The dried gel was put into a drying cabinet, dried at 120°C for 24h, ground and placed in a SX1000 muffle furnace, heated to 600°C for 2h for calcination. The calcined powder was placed in a tubular hydrogen reduction furnace, heated to 600°C in a hydrogen atmosphere, kept at 950°C for 1 hour, and kept at 1 hour to obtain scandium oxide-doped tungsten powder. Afterwards, the process of pressing and microwave sintering is carried out, and the sintering temperature is 1450°C. Then press and sinter the tungsten powder, keep the pressure at 0.55MPa for 20s, keep the sintering temperature at 1480°C for 20min, then impregnate 411 barium aluminate calcium salt, the impregnation temperature is 1675°C, the impregnation amount is 6-7%, and the tempe...

Embodiment 2

[0027] Example 2 Dissolve 129.7g of ammonium metatungstate, 10.1g of scandium nitrate, and 139.8g of citric acid in deionized water respectively, stir thoroughly and mix, put the mixed solution into a water bath and heat to obtain a light yellow xerogel. The dried gel was put into a drying cabinet, dried at 120°C for 24h, ground and placed in a SX1000 muffle furnace, heated to 600°C for 2h for calcination. The calcined powder was placed in a tubular hydrogen reduction furnace, heated to 600°C in a hydrogen atmosphere, kept at 950°C for 1 hour, and kept at 1 hour to obtain scandium oxide-doped tungsten powder. Afterwards, the process of pressing and microwave sintering is carried out, and the sintering temperature is 1450°C. Then press and sinter the tungsten powder, keep the pressure at 0.55MPa for 20s, keep the sintering temperature at 1480°C for 20min, then impregnate 411 barium aluminate calcium salt, the impregnation temperature is 1675°C, the impregnation amount is 6-7%, ...

Embodiment 3

[0028] Example 3 Dissolve 132.4g of ammonium metatungstate, 3.35g of scandium nitrate, and 135.8g of citric acid in deionized water respectively, mix them after fully stirring, put the mixed solution into a water bath and heat to obtain a light yellow xerogel, The dried gel was put into a drying cabinet, dried at 120°C for 24h, ground and placed in a SX1000 muffle furnace, heated to 600°C for 2h for calcination. The calcined powder was placed in a tubular hydrogen reduction furnace, heated to 600°C in a hydrogen atmosphere, kept at 950°C for 1 hour, and kept at 1 hour to obtain scandium oxide-doped tungsten powder. Afterwards, the process of pressing and microwave sintering is carried out, and the sintering temperature is 1450°C. Then press and sinter the tungsten powder, keep the pressure at 0.55MPa for 20s, keep the sintering temperature at 1480°C for 20min, then impregnate 411 barium aluminate calcium salt, the impregnation temperature is 1675°C, the impregnation amount is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com