Preparation method of mugwort extract hand sanitizer with bacteriostasis and disinfection effects

A technology of extract and hand sanitizer, which is applied in the field of mugwort extract hand sanitizer and its preparation, can solve the problems of irritation and corrosion in the stomach, protect the skin of the hands, have a good sticky effect, and leave residue on the hands Fragrant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Powder 200 g of dried mugwort leaves, put the dry powder in a closed extraction tank, vacuumize until the vacuum in the extraction tank reaches -100 kPa, and inject DME into the extraction tank (v / v, 1: 0.5) , the sample is completely submerged, the mass volume ratio of the raw material and the mixed extraction solvent is 1:10 g / ml, the extraction time is 25 minutes, the temperature is 40 ℃, the pressure is 0.5 Mpa, and the extraction is circulated twice; after the extraction, the liquid solvent is pumped into the separation tank , the extraction tank and the separation tank were subjected to constant temperature precipitation treatment at the same time, the precipitation temperature was 40°C, and the extracted sample and extract were obtained respectively; Distilled for 120 minutes, separated by an oil-water separator to obtain mugwort essential oil and pure dew.

[0031] After the resulting distillation is completed, the light components are collected and the mass vol...

Embodiment 2

[0039] Powder 200 g of dried mugwort leaves, put the dry powder in a closed extraction tank, vacuumize until the vacuum in the extraction tank reaches -100 kPa, and inject DME into the extraction tank (v / v, 1: 0.5) , the sample is completely submerged, the mass volume ratio of the raw material and the mixed extraction solvent is 1:10 g / ml, the extraction time is 25 minutes, the temperature is 40 ℃, the pressure is 0.5 Mpa, and the extraction is circulated twice; after the extraction, the liquid solvent is pumped into the separation tank , the extraction tank and the separation tank are subjected to constant temperature precipitating treatment at the same time, the desolventizing temperature is 40°C, and the extracted sample and extract are respectively obtained; the obtained extract is mixed with distilled water at a mass volume ratio of 1: 1g / ml, and distilled at 100°C After 90 min, the essential oil and pure dew of mugwort were separated by an oil-water separator.

[0040]Af...

Embodiment 3

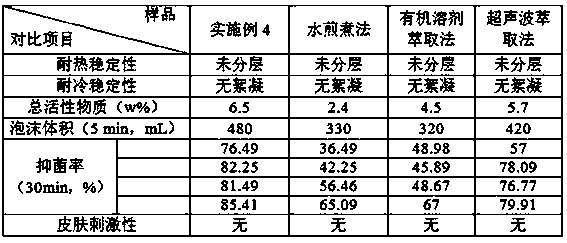

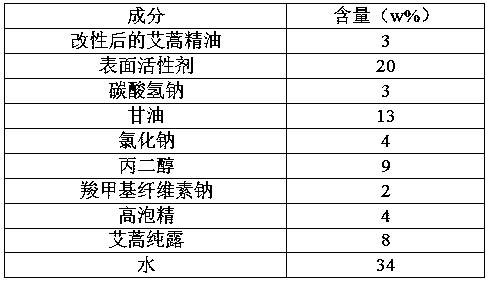

[0048] Take the modified mugwort essential oil prepared in Example 1, mix the components according to the formula shown in Table 5, and homogenize at a speed of 10000 rpm for 5 min to obtain the mugwort antibacterial hand sanitizer.

[0049] Table 5 The formula of embodiment 3 mugwort antibacterial hand sanitizer

[0050]

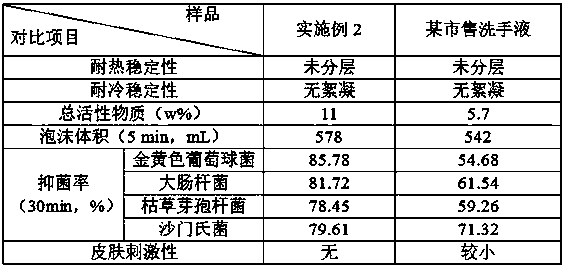

[0051] The performance of the Artemisia Artemisiae antibacterial hand sanitizer made in the present embodiment is shown in Table 6. As can be seen from the table, the hand sanitizer prepared by Example 3 of the present invention has good heat-resistant stability, cold-resistant stability and 5 min foam volume performance. Bacillus, Salmonella and other strains are significantly better than a commercially available hand sanitizer in terms of inhibitory performance, and it is non-irritating to the skin. It is a product that meets the needs of the people for a better life.

[0052] Table 6 The performance of Artemisia Artemisiae antibacterial hand sanitize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com