Application of Discharge Activated Water to Prepare Improved Nutrient Solution

A nutrient solution, activated water technology, applied in electrochemical water/sewage treatment, application, liquid fertilizer and other directions, can solve the problems of complex formula ratio, chemical residues and other problems, achieve easy absorption and circulation, promote enzyme activity, enhance water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

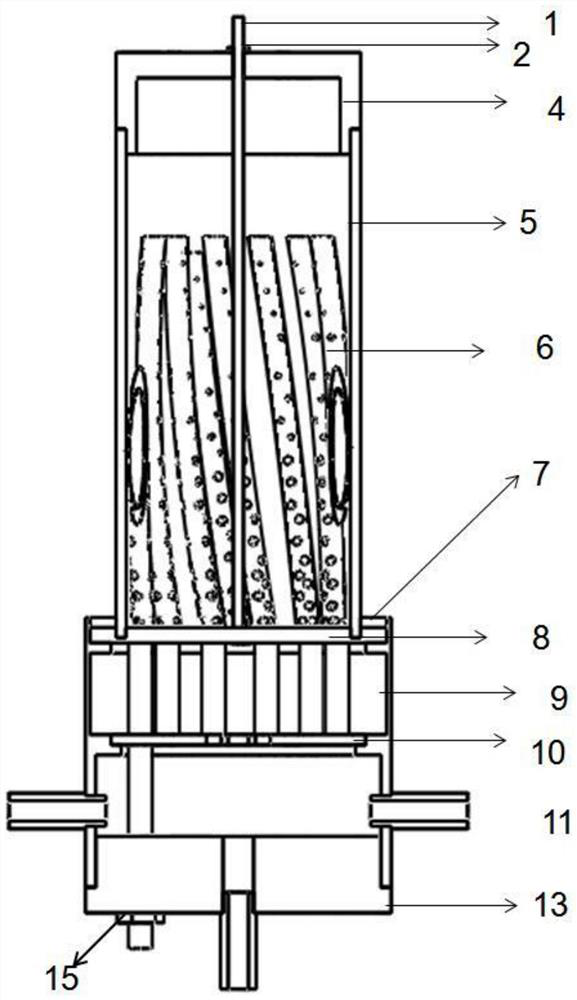

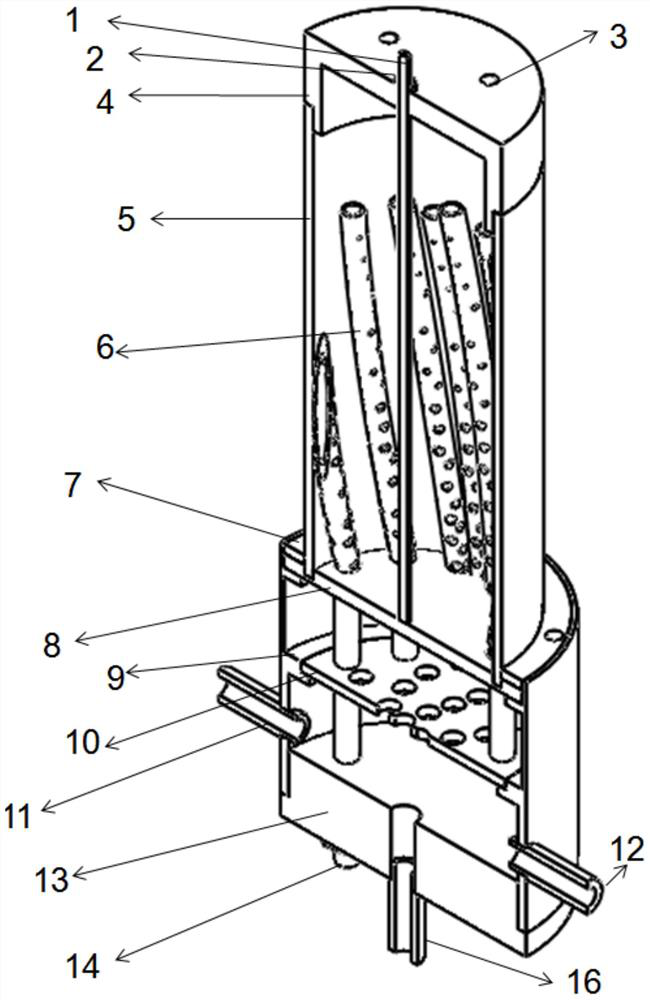

[0052] Example 1 Preparation of discharge activated water

[0053] 1. Discharge activation water preparation: utilization Figure 1-3 The plasma activated water preparation apparatus shown is prepared by discharging activation water, an AC voltage 10 kV, frequency 9 kHz, and an electrode I14, and the electrode I1 is connected to the ground, and the air flow rate is 1 SLM, which is inflowed by the air hole IV16, an additional air hole III12. It can be used to add helium, argon, nitrogen, and other auxiliary gases. 100 ml of deionized aqueous solution is added to the medium tube I5, and the discharge voltage is 5 min, and the 1 time deionized water discharge activation treatment is performed to obtain 100 mL discharge activated aqueous solution. Adopt Figure 1 The devices shown are prepared by discharging activated water (AC: peak - peak 5, 6, 7, 8, 9, 10 kV, frequency 1, 2, 3, 4, 5, 6, 7, 8, 9, 10kHz; pulse: peak 3, 4, 5, 6, 7, 8, 9, 10kV, frequency 1, 3, 4, 5, 6, 7, 8, 9, 10 kHz), ...

Embodiment 2

[0054] Example 2 Preparation of Modified Nutrient Liquid

[0055] Take 135 mg of dihydrogen phosphate, 490 mg of magnesium sulfate, 2.5 ml of iron salt solution, 4 ml of trace elements, and activate water 1L;

[0056] The iron salt solution includes 13mg of sevili sulfate, 12 mg of dice sodium ethylenediamine tetra acetate, 2.5 ml of distilled water;

[0057] The trace element fluid comprises 0.00410 mg of potassium iodide, 0.030 mg of boric acid, manganese sulfate, 0.040 mg of sulfate, 0.00120 mg of molybdate, 0.000 mg of copper sulfate, cobalt chloride 0.000120 mg.

Embodiment 3

[0058] Example 3 Improved nutrient preparation

[0059] It is called 140 mg of pelicate, 500 mg of magnesium sulfate, 2.5 ml of iron salt solution, 5 ml of trace element liquid, and activated water 1L;

[0060] The iron salt solution includes a ferrous iron sulfate 14mg, dice sodium ethylenediamine, 2.5 ml of distilled water;

[0061] The trace element fluid comprises 0.00420 mg of iodide, 0.035 mg of boric acid, manganese sulfate, 0.045 mg of sulfate, 0.00130 mg of sodium molybdate, 0.000 mg of sulfate, cobalt chloride 0.000 mg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com