ABS composite material for arc-shaped edge banding, preparation method thereof and arc-shaped edge banding obtained from preparation method

A composite material and edge banding technology, which is applied in the field of edge banding, can solve the problems of not being able to meet the heat resistance, environmental protection and safety requirements of high-end furniture, unfavorable application of curved edge banding, high bending strength, etc., and achieve Improve heat distortion temperature and dimensional stability, improve structure precipitation, and improve thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

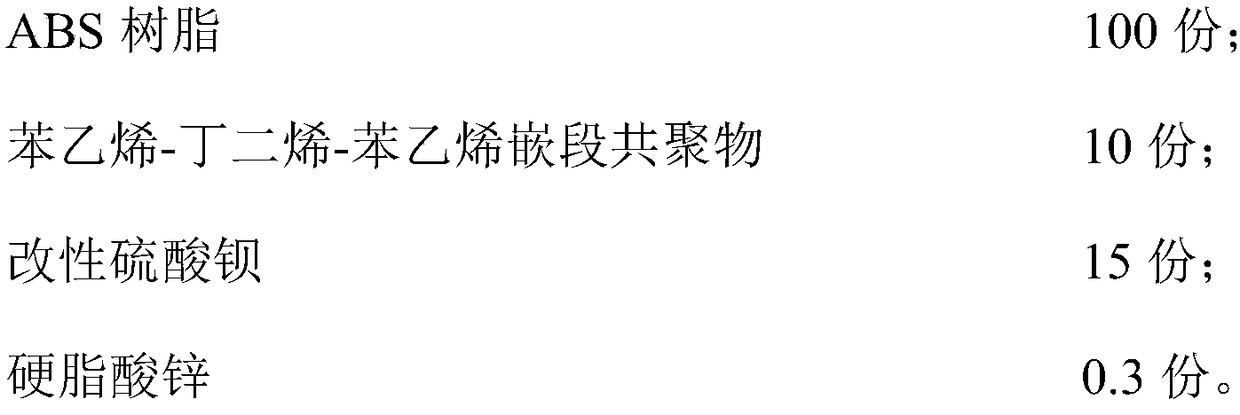

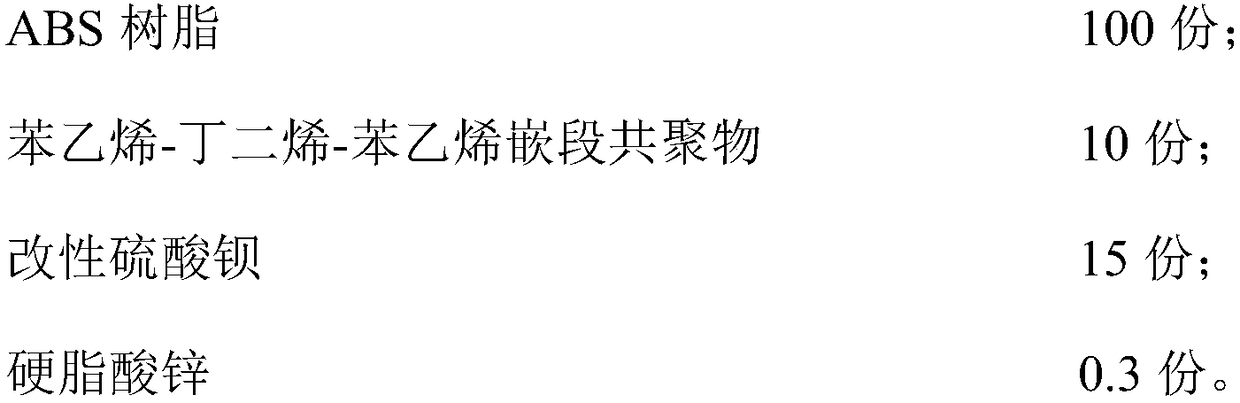

[0041] An ABS composite material consists of the following components in parts by weight:

[0042]

[0043] Wherein, in ABS resin, the content of butadiene unit is 30wt%; In styrene-butadiene-styrene block copolymer, the content of butadiene unit is 35wt%; The particle diameter of zinc stearate is 23 μm.

[0044] The preparation method is as follows:

[0045] The ABS resin, the styrene-butadiene-styrene block copolymer, the modified barium sulfate and the zinc stearate are blended and extruded in an extruder to obtain the ABS composite material.

[0046] The working parameters of the extruder are: barrel one zone 180°C, barrel two zone 182°C, barrel three zone 185°C, barrel four zone 188°C, barrel five zone 190°C, confluence core temperature 165°C, mold The first zone of the head is 180°C, and the second zone of the die is 190°C.

Embodiment 2-3

[0048] The only difference from Example 1 is that in this example, the amount of styrene-butadiene-styrene block copolymer is 5 parts (Example 2) and 15 parts (Example 3).

Embodiment 4-6

[0050] The only difference with Example 1 is that in this example, in the styrene-butadiene-styrene block copolymer, the content of butadiene units is 40wt% (embodiment 4), 28wt% (implementation Example 5), 48wt% (embodiment 6).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| crimp elongation | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com