High thermal and electrical conductive silver colloid and preparation method thereof

A technology of conductive silver glue and high thermal conductivity, which is applied in the direction of conductive adhesives, adhesives, epoxy resin glue, etc., can solve the problems that limit the wide application in the field of electronic packaging, improve mechanical properties, improve electrical and thermal conductivity, and enhance electrical conductivity and the effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

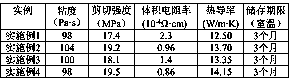

Embodiment 1

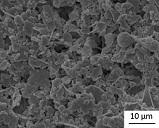

[0027] A high thermal conductivity and conductive silver glue and a preparation method thereof, comprising the following raw material components in the following mass percentages:

[0028] Micron silver flake 79%, nano silver wire 2%, bisphenol F resin 14.2%, dicyandiamide 2.3%, trimethylolethane triglycidyl ether 1%, SnBi57Ag1 1.0%, TEGO Foamex N 0.1%, TEGO410 0.1%, TEGO Dispers 755W0.3%.

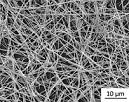

[0029] The particle size of the micron silver flakes is 5-9 microns. Described nano-silver wire is obtained by the following method: the silver nitrate of 1 weight part, the polyvinylpyrrolidone K30 of 1 weight part and the sodium sulfide of 0.014 weight part and the ethylene glycol of 100 weight parts are mixed and stirred and transferred to hydrothermal reaction In the kettle, react at 160°C for 150 minutes, and then cool to room temperature. The reaction product was washed twice with acetone, then three times with deionized water, and finally once with absolute ethanol to obtain silve...

Embodiment 2

[0032] A high thermal conductivity and conductive silver glue and a preparation method thereof, comprising the following raw material components in the following mass percentages:

[0033] Micron silver flake 74%, nano silver wire 3%, bisphenol F resin 16.5%, dicyandiamide 3.0%, trimethylolethane triglycidyl ether 1%, SnBi57Ag1 2.0%, TEGO Foamex N 0.1%, TEGO410 0.1%, TEGO Dispers 755W0.3%.

[0034] The particle size of the micron silver flakes is 5-9 microns. Described nano-silver wire is obtained by the following method: the silver nitrate of 1 weight part, the polyvinylpyrrolidone K30 of 1 weight part and the sodium sulfide of 0.014 weight part and the ethylene glycol of 100 weight parts are mixed and stirred and transferred to hydrothermal reaction In the kettle, react at 160°C for 150 minutes, and then cool to room temperature. The reaction product was washed twice with acetone, then three times with deionized water, and finally once with absolute ethanol to obtain silve...

Embodiment 3

[0037] A high thermal conductivity and conductive silver glue and a preparation method thereof, comprising the following raw material components in the following mass percentages:

[0038] Micron silver flake 76%, nano silver wire 3%, bisphenol F resin 15.5%, dicyandiamide 2.6%, trimethylolethane triglycidyl ether 1%, SnBi57Ag1 1.4%, TEGO Foamex N 0.1%, TEGO410 0.1%, TEGO Dispers 755W0.3%.

[0039] The particle size of the micron silver flakes is 5-9 microns. Described nano-silver wire is obtained by the following method: the silver nitrate of 1 weight part, the polyvinylpyrrolidone K30 of 1 weight part and the sodium sulfide of 0.014 weight part and the ethylene glycol of 100 weight parts are mixed and stirred and transferred to hydrothermal reaction In the kettle, react at 160°C for 150 minutes, and then cool to room temperature. The reaction product was washed twice with acetone, then three times with deionized water, and finally once with absolute ethanol to obtain silve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com