Method for modifying straw biochar for remediating heavy metal contaminated soil

A technology for polluted soil and straw organisms, which is applied in the restoration of polluted soil, soil conditioning materials, chemical instruments and methods, etc. The method is simple and easy to implement, and the repair efficiency is stable and reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

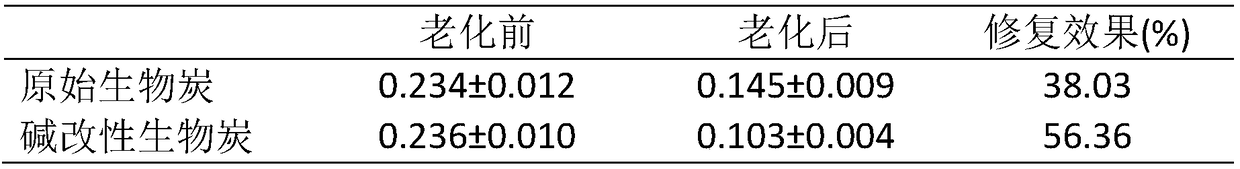

[0034] Example 1: Comparison of restoration effect with non-modified biochar

[0035] The specific implementation process is as follows:

[0036] 1. Bake corn stalks at 70°C for 9 hours, then dry, crush and sieving through 50 mesh;

[0037] 2. Put the powdered corn stalks into a box-type atmosphere furnace (KSFQ1100, Jiangsu Qianjin Furnace Equipment Co., Ltd.), pour nitrogen into it to maintain anaerobic conditions, heat it to 500°C and then pyrolyze it for 3 hours, then cool it to room temperature. After repeated washing with deionized water, the original biochar can be obtained after drying at 70°C for 4 hours;

[0038] 3. Then invade 30% sodium hydroxide at a mass ratio of 1:7.5, stir and repeatedly rinse with deionized water, and dry at 70°C for 4 hours to obtain alkali-modified biochar;

[0039] 4. Apply the original biochar and alkali-modified biochar into the soil (moist brown soil) contaminated by Cd (total amount 2.3mg / Kg) at a mass ratio of 1%, and then naturally age for 3 m...

Embodiment 2

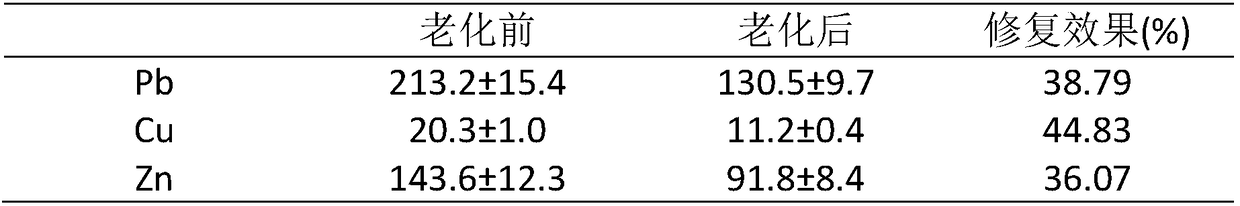

[0044] Example 2: The effect of alkali-modified biochar to remediate red soil polluted by multiple heavy metals

[0045] 1. After drying the rice straw at 70°C, crush it and sieve 50 meshes;

[0046] 2. Put the powdered rice straw into a box-type atmosphere furnace, bubbling with nitrogen to maintain anaerobic conditions, heat to 400°C and then pyrolyze for 2 hours, cool to room temperature, repeatedly wash with deionized water, and dry at 70°C for 4 hours Then get the original biological carbon;

[0047] 3. Then invade 30% sodium hydroxide at a volume ratio of 1:5, stir and rinse with deionized water repeatedly, and dry at 70°C for 4 hours to obtain alkali-modified biochar;

[0048] 4. Apply alkali-modified biochar into the soil (red soil) polluted by multiple heavy metals (Pb, Cu and Zn) (total 1122.5, 153.9 and 950.2 mg / kg) at a mass ratio of 1%, and naturally age after mixing 2 months;

[0049] 5. Use 0.01moL CaCl 2 The solution extracts the effective Pb, Cu and Zn in the soil, an...

Embodiment 3

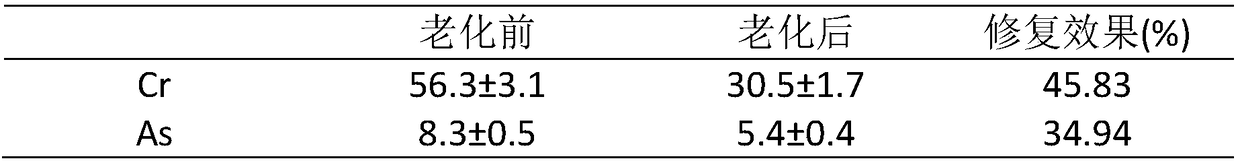

[0053] Example 3: The effect of alkali-modified biochar to remediate black soil contaminated by various heavy metals

[0054] 1. After drying the rice straw at 70°C (8 hours), crush it through a sieve of 50 mesh;

[0055] 2. Put the powdered rice straw into a box-type atmosphere furnace, bubbling with nitrogen to maintain anaerobic conditions, heat to 400°C and then pyrolyze for 2 hours, cool to room temperature, repeatedly wash with deionized water, and dry at 70°C for 4 hours The original biochar is obtained afterwards;

[0056] 3. Then invade 30% sodium hydroxide at a volume ratio of 1:5, stir and rinse with deionized water repeatedly, and dry at 70°C for 4 hours to obtain alkali-modified biochar;

[0057] 4. Apply the alkali-modified biochar into the soil (red soil) polluted by multiple heavy metals (Cr and As) (total 321.5 and 56.3 mg / kg) at a mass ratio of 1%, and naturally age for 2 months after mixing;

[0058] 5. Use 0.01moL CaCl 2 The solution extracts the available Cr and As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com