Preparation method of thais clayigera antihypertensive peptide

A technology of twig snail and antihypertensive peptide, which is applied in the field of preparation of twig snail antihypertensive peptide, can solve the problems of unfavorable industrialized production and high development cost, and achieve the effects of simple and feasible preparation method, convenient operation and mild conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of snail snail antihypertensive peptide, the method:

[0033] 1) Provide snail snail slurry, which is the homogenate after removing impurities from snail snail;

[0034]2) providing at least one protease to enzymatically hydrolyze the above slurry to obtain an enzymatic hydrolyzate;

[0035] 3) Provide ultrasound to assist the above-mentioned enzymatic hydrolysis;

[0036] 4) Provide debitterization and purification treatment of the above enzymatic hydrolyzate, and dry to obtain the antihypertensive peptide;

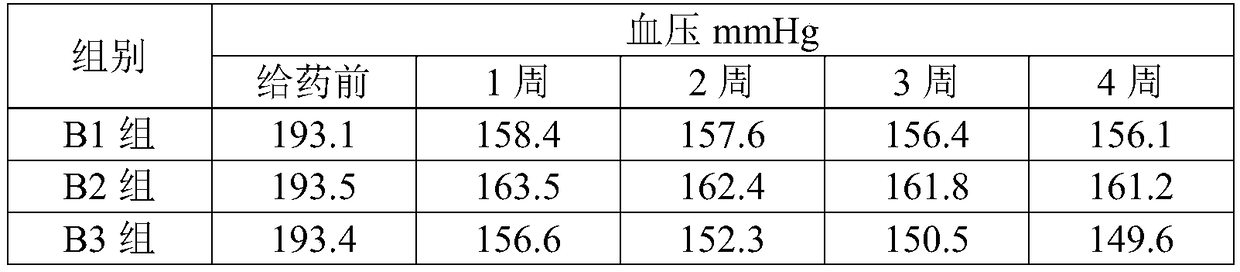

[0037] The molecular weight of the snail snail antihypertensive peptide is 250-2500 Da. The antihypertensive peptide obtained by the method is derived from food protein, has a significant inhibitory effect on ACE, and can play a role in lowering blood pressure for hypertensive patients, but has no antihypertensive effect on normal blood pressure patients. Blood sugar, immune enhancement and other functions, these peptides are obtained by en...

Embodiment 2

[0048] A preparation method of snail snail antihypertensive peptide, the specific steps are as follows:

[0049] 1) Add 2% NaOH solution to the lychee snail meat according to the material-liquid ratio of 1:7, soak for 1 hour, wash with water until neutral, and then add 7% NaOH solution according to the material-liquid ratio of 1:9. Soak in propanol solution for 2 hours, wash and crush, then place in a 6000r / min homogenizer and homogenize for 10 minutes to obtain snail liquid. The isopropanol solution contains 0.43mM 4-methyl-2-pentane Alcohol, wherein the weight ratio of L-isomer is 48%;

[0050] 2) Sterilize the snail slurry at 85°C for 10 minutes, then adjust the pH of the slurry to 7, add neutral protease to the slurry, the amount of enzyme added is 110KU / 100g, react at a temperature of 50°C for 8.5h, and at the same time assist With a frequency of 40kHz and a power of 200mW / cm 2 The sinusoidal ultrasonic wave and the vibration treatment with a rotation speed of 200rpm, a...

Embodiment 3

[0056] A preparation method of snail snail antihypertensive peptide, the specific steps are as follows:

[0057] 1) Add NaOH solution with a concentration of 1.5% to the lychee snail meat according to the ratio of material to liquid at 1:6, soak for 1.5 hours, wash with water until neutral, and then add NaOH solution at a concentration of 6% according to the ratio of material to liquid at 1:7 Soak in isopropanol solution for 2.5h, wash and crush, then place in a 5000r / min homogenizer and homogenize for 15min to obtain snail snail slurry. The above-mentioned isopropanol solution contains 0.38mM 4-methyl-2 -amyl alcohol, wherein the proportion of L-isomer weight is 45%;

[0058] 2) Sterilize the snail slurry at 80°C for 10 minutes, then adjust the pH of the slurry to 7.5, add neutral protease to the slurry at a rate of 80KU / 100g, and react at a temperature of 45°C for 9 hours, supplemented with Frequency 40kHz, power 200mW / cm 2 The sinusoidal ultrasonic wave and the vibration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ic50 | aaaaa | aaaaa |

| Ic50 | aaaaa | aaaaa |

| Ic50 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com