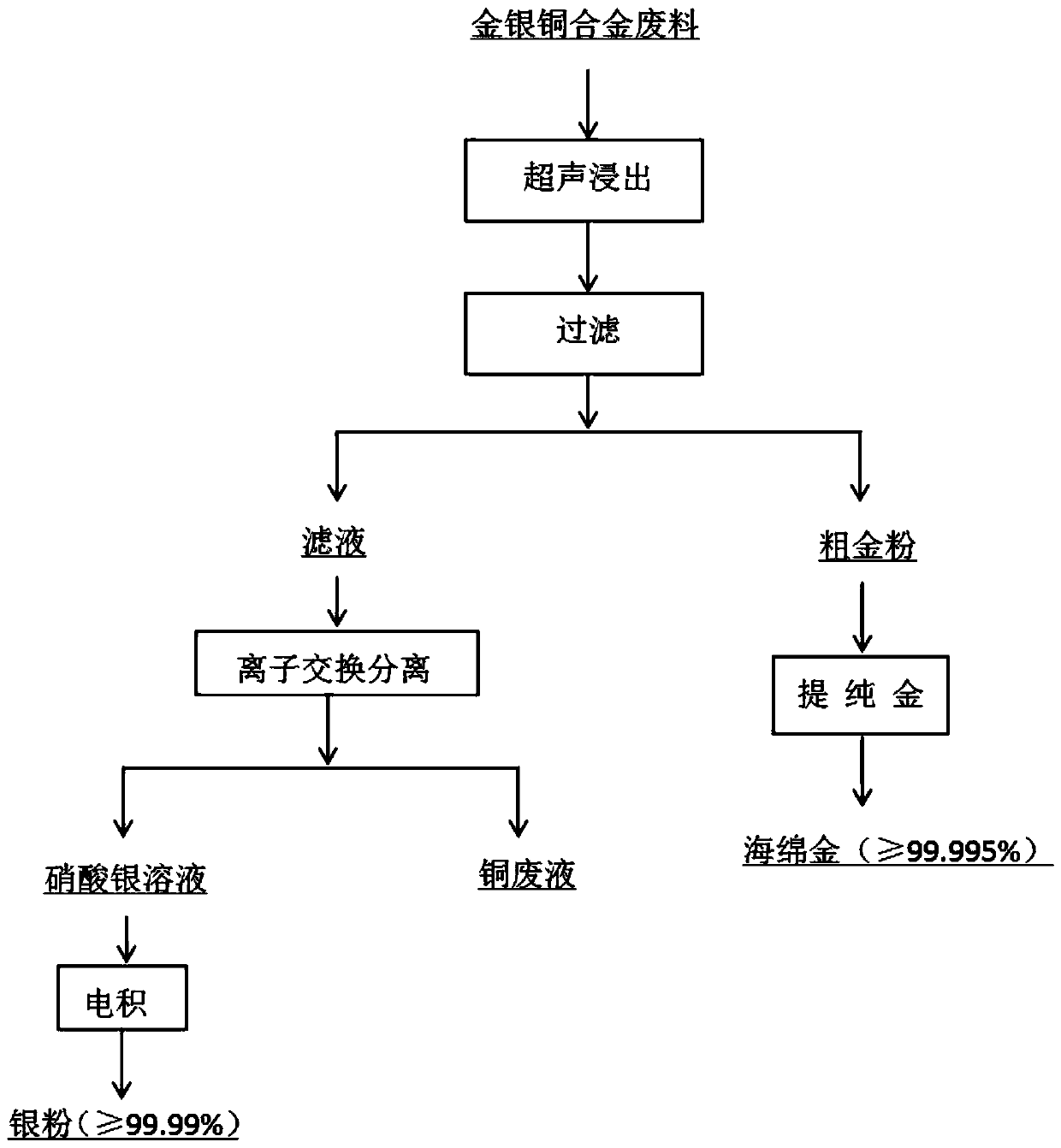

A method for recovering gold and silver in gold-silver-copper alloy waste

A copper alloy and scrap technology, which is applied to the improvement of process efficiency, instruments, optics, etc., can solve the problems of shortening the recovery process and difficulty in dissolving gold, silver and copper alloy waste, so as to shorten the recovery process, speed up the dissolution rate and achieve good separation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The mass content of gold in the gold-silver-copper alloy scrap of this embodiment is 60%, the mass content of silver is 35%, and the balance is copper and other unavoidable impurities, and the method for reclaiming gold and silver in the gold-silver-copper alloy scrap includes The following steps:

[0034] Step 1. Put the gold, silver and copper alloy scraps in an ultrasonic reaction kettle whose liner is made of titanium, then add concentrated nitric acid with a mass percentage concentration of 68% into the ultrasonic reaction kettle, and ultrasonically leach at 65°C for 6 hours under stirring conditions After filtration, the filtrate and filter residue are obtained, and the ultrasonic frequency is 80KHz; the filter residue is coarse gold powder with a particle size of 50 μm to 100 μm;

[0035] Step 2, diluting the filtrate described in step 1 to a silver content of 5mg / L with deionized water, then adopting pretreated sulfonic acid group strong acidic cation exchange r...

Embodiment 2

[0044] The mass content of gold in the gold-silver-copper alloy scrap of this embodiment is 70%, the mass content of silver is 20%, and the balance is copper and other unavoidable impurities. The method for reclaiming gold and silver in the gold-silver-copper alloy scrap includes The following steps:

[0045] Step 1. Put the gold, silver and copper alloy scraps in an ultrasonic reaction kettle whose liner is made of titanium, then add concentrated nitric acid with a concentration of 65% by mass into the ultrasonic reaction kettle, and ultrasonically leach at 78°C for 5 hours under agitation. After filtration, the filtrate and filter residue are obtained, and the ultrasonic frequency is 100KHz; the filter residue is coarse gold powder with a particle size of 50 μm to 100 μm;

[0046] Step 2, diluting the filtrate described in step 1 to a silver content of 8 mg / L with deionized water, then adopting pretreated sulfonic acid group strong acidic cation exchange resin to carry out i...

Embodiment 3

[0055] The mass content of gold in the gold-silver-copper alloy scrap of this embodiment is 50%, the mass content of silver is 20%, and the balance is copper and other unavoidable impurities. The method for reclaiming gold and silver in the gold-silver-copper alloy scrap includes The following steps:

[0056] Step 1. Put the gold, silver and copper alloy scraps in an ultrasonic reaction kettle whose liner is made of titanium, then add concentrated nitric acid with a concentration of 65% by mass into the ultrasonic reaction kettle, and ultrasonically leach at 80°C for 4 hours under agitation. After filtration, the filtrate and filter residue are obtained, and the ultrasonic frequency is 110KHz; the filter residue is coarse gold powder with a particle size of 50 μm to 100 μm;

[0057] Step 2, diluting the filtrate described in step 1 to a silver content of 10 mg / L with deionized water, then adopting pretreated sulfonic acid group strong acidic cation exchange resin to carry out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com