Multifunctional integrated composite electrode slurry material containing active carbonyl polymer and preparation method of slurry material

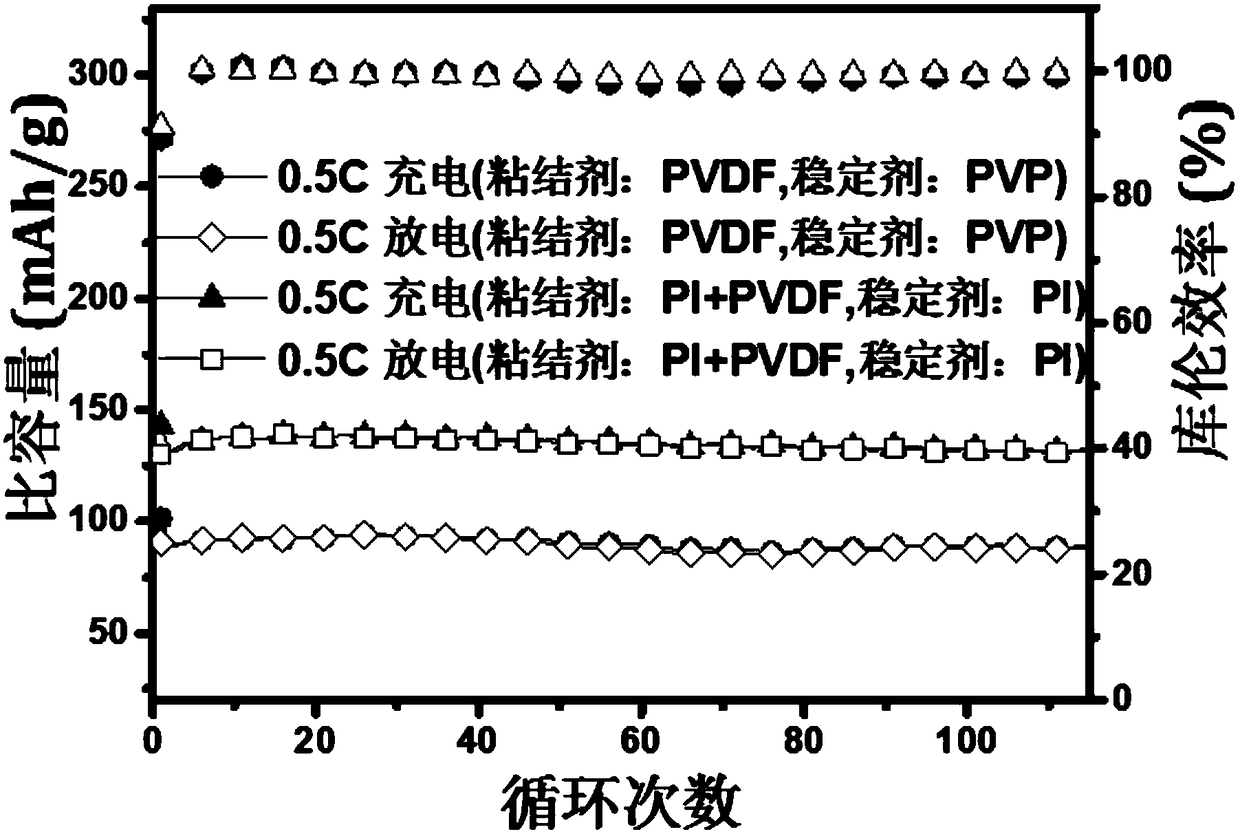

A composite electrode and electrode slurry technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of lower battery energy density, slow lithium ion diffusion, lower battery power density, etc. Effects of chemical activity, improved lithium ion diffusivity, and electrode stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

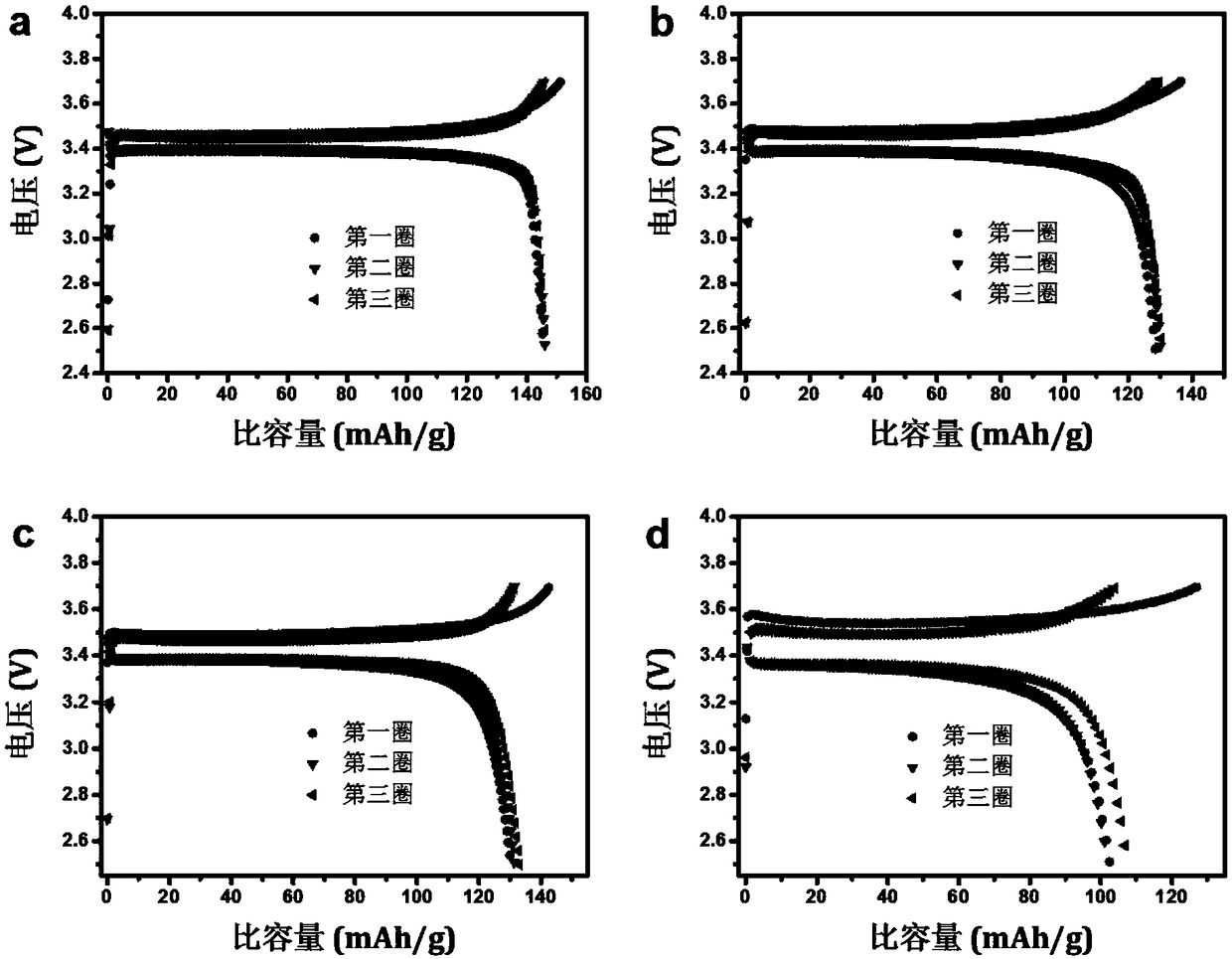

[0024] The first embodiment provides a polyimide-containing lithium iron phosphate electrode slurry and a preparation method thereof.

[0025] Preparation:

[0026] 1) Weigh 30.08g of lithium iron phosphate, 0.48g of carbon black, add 12.12g of N-methylpyrrolidone (NMP), mix evenly, put into a double planetary vacuum mixer and stir in three stages for 10min, 20min, 90min respectively, set the speed They are 100rpm, 300rpm and 500rpm respectively.

[0027] 2) Add 0.48g of carbon nanotubes to 9.024g of NMP, ultrasonically disperse for 3 hours, then add 0.096g of polyimide (made from 1,4,5,8-naphthalene tetracarboxylic anhydride and 1,3,5-tri(4 - aminobenzene) benzene synthesis), magnetic stirring at 450rpm for 2h to make a stable carbon nanotube dispersion.

[0028] 3) Weigh 0.544g of the above-mentioned polyimide and 0.64g of polyvinylidene fluoride (PVDF), respectively, add 7.1g of solvent NMP, and magnetically stir at 500rpm for 12h to prepare a mixed solution.

[0029] 4)...

Embodiment 2

[0036] The preparation method of the polyimide-containing lithium iron phosphate electrode slurry provided in this embodiment 2 includes the following steps:

[0037] 1) Weigh 28.96g of lithium iron phosphate and 0.224g of carbon black, add them to 8g of NMP, mix them evenly, put them into a double planetary vacuum mixer and stir them in three stages for 10min, 10min, and 90min respectively, and set the speeds at 100rpm, 200rpm, and 500rpm respectively.

[0038] 2) Add 0.256g of graphene powder to 4.76g of NMP, after ultrasonic dispersion for 2h, add 0.1024g of polyimide (synthesized from 1,4,5,8-naphthalene tetracarboxylic anhydride and sunflower diamine), at 500rpm Stir magnetically for 2 hours to prepare a stable graphene dispersion.

[0039] 3) Weigh 1.2g of polyvinylidene fluoride (PVDF) as a binder, and weigh 1.2g of the above-mentioned polyimide, add it to 5g of NMP, stir magnetically at 500rpm for 12h, and prepare a binder solution.

[0040] 4) The graphene dispersion...

Embodiment 3

[0043] The preparation method of the lithium cobaltate electrode slurry containing polyimide and polymethyl methacrylate (PMMA) provided in the present embodiment three comprises the steps:

[0044] 1) Weigh 28.8g of lithium cobaltate, 0.64g of carbon black, add 12.12g of solvent NMP, mix evenly, put into a double planetary vacuum mixer and stir for 20min and 90min respectively in two stages, and set the speed at 300rpm and 500rpm respectively.

[0045] 2) Add 0.64g graphene powder to 12.032g NMP, ultrasonically disperse for 2 hours, add 0.064g polyimide (synthesized from pyromellitic anhydride and p-phenylenediamine), 0.064 polyvinylpyrrolidone, magnetic force at 500rpm Stir for 2h to make a stable graphene dispersion.

[0046] 3) Weigh 1.792g of polymethyl methacrylate (PMMA) to replace the binder, add 8g of solvent NMP, and stir magnetically at 500rpm for 12h to make a solution.

[0047] 4) Add the graphene dispersion to the stirred lithium cobaltate and carbon black mixtu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com