A device for separating oxygen from air

A technology for separating air and oxygen, which is applied in the direction of oxygen preparation, specific gas purification/separation, oxygen/ozone/oxide/hydroxide, etc. It can solve the problems of small amount of enriched oxygen, low concentration of enriched oxygen, and detachment. Achieve the effects of simple equipment, improved separation effect and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

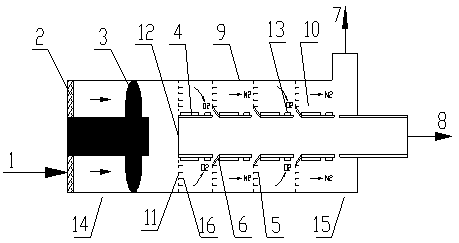

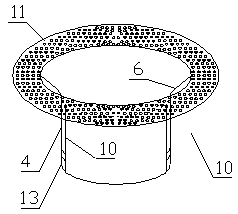

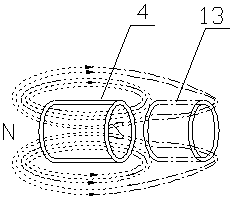

[0034] use figure 1 Oxygen separator and air filter 2 are made of stainless steel wire mesh with a pore diameter of 4mm. Blower 3 uses an axial flow fan. The inlet pressure of blower 3 is -0.1kPa, and the outlet pressure of blower 3 is 14kPa. The distance between the assembly 5 and the center of the magnetic assembly 4 is twice the length of the magnetic assembly 4, the center distance between the magnetic field transformation assembly 13 and the magnetic assembly 4 is twice the length of the magnetic assembly 4, and the length of several corona rods 16 is 40mm. The radius of the inner ring of the sieve plate 11 is consistent with the outer radius of the deflector 6, the radius of the outer ring of the sieve plate 11 is three times the radius of the inner ring, and the opening ratio of the sieve plate 11 is 50%. The magnetic field conversion component 13 is a magnetic shield circular cylindrical structure made of iron alloy, and its length is 1 / 2 of the length of the magnetic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com