Self-crosslinking fluorine-containing macromolecular emulsifier, fluorine-containing emulsion containing said emulsifier, preparation and use method thereof

A macromolecular emulsifier and self-crosslinking technology, which is applied in the field of fluorine-containing emulsions and self-crosslinking fluorine-containing macromolecular emulsifiers, can solve the problem of damage to the hydrophobicity of the coating, the decline in the performance of the fluoropolymer, and the impact on the hydrophobicity of the coating , anti-adhesion, hydrophobic stability and long-term effect, etc., to achieve the effect of easy operation of the polymerization process, fast polymerization speed and high molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

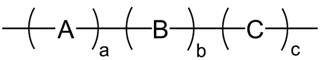

[0083] Synthesis of fluorine-containing emulsion E1 containing self-crosslinking fluorine-containing macromolecular emulsifier:

[0084] Add 100ml N in the reactor, N dimethylacetamide (DMAC), perfluorooctyl ethyl acrylate 6g, methyl methacrylate 6g, hydroxyethyl acrylamide 8g, initiator benzoyl peroxide (BPO ) 0.2g, dissolve and stir at room temperature for 30 minutes under nitrogen flow to remove oxygen in the system. Under the condition of reflux, the temperature was raised to 60° C. for polymerization, and the polymerization reaction was carried out. After 6 hours of reaction, heating was stopped, and air was introduced to terminate the reaction to obtain a fluorine-containing macromolecular emulsifier. After discharging, 300 g of perfluorooctyl ethyl acrylate, 300 g of methyl methacrylate, 50 g of the fluorine-containing macromolecular emulsifier solution prepared above, and 2000 ml of deionized water were pre-emulsified with a supersonic emulsifier at room temperature f...

Embodiment 2

[0089] Synthesis of fluorine-containing emulsion E2 containing self-crosslinking fluorine-containing macromolecular emulsifier:

[0090] The synthesis process of E2 refers to Example 1, and the formula and process parameters are shown in Table 1 and Table 2 respectively.

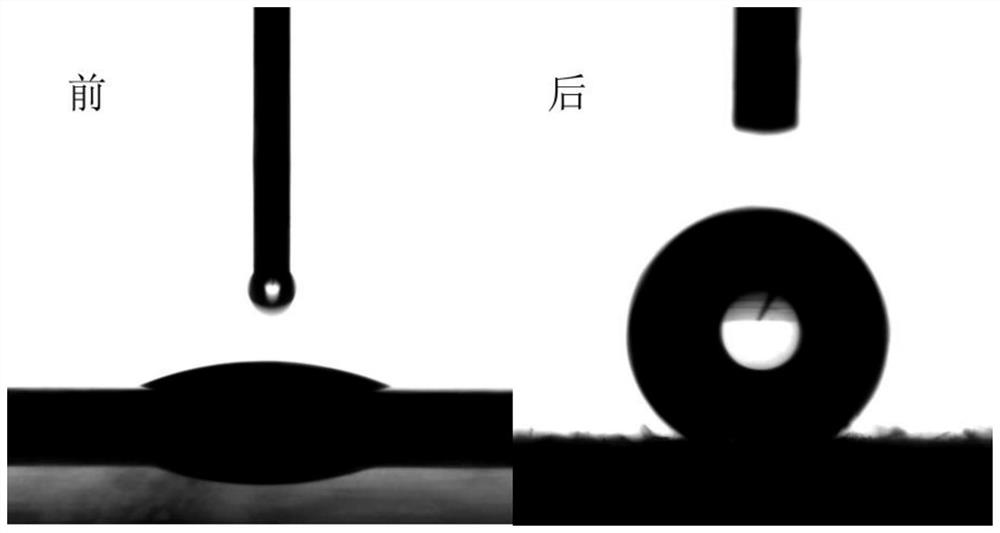

[0091] E2 structure and performance characterization methods are the same as those in Example 1. The molecular weight, molecular weight distribution and fluorine content of E2 are shown in Table 3; the contact angle changes of the glass fiber non-woven membrane before and after being treated with E2 coating film are shown in Table 4.

Embodiment 3

[0093] Synthesis of fluorine-containing emulsion E3 containing self-crosslinking fluorine-containing macromolecular emulsifier:

[0094] The synthesis process of E3 refers to Example 1, and the formula and process parameters are shown in Table 1 and Table 2 respectively.

[0095] The method for characterizing the structure and performance of E3 is the same as that of Example 1. The molecular weight, molecular weight distribution and fluorine content of E3 are shown in Table 3; the contact angle changes of the glass fiber non-woven membrane before and after being treated with E3 coating film are shown in Table 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com