A kind of fine desulfurizer of zinc oxide at normal temperature and its preparation method and application

A fine desulfurizer and zinc oxide technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as difficult product industrialization, complicated process, waste of anhydrous ethanol, etc., and achieve a simple and easy preparation strategy , small particle size, uniform dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

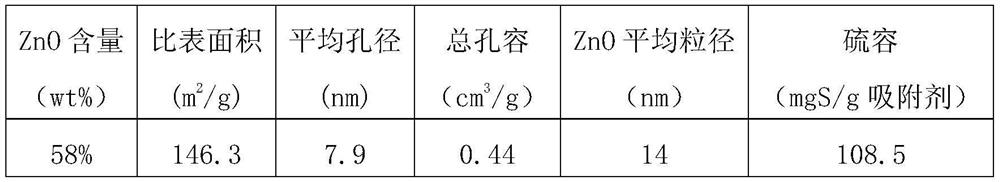

Embodiment 1

[0024] Add 9mL TEOS, 7mL absolute ethanol, 1.1mL deionized water, 0.3mL dilute nitric acid (4mol / L) into a 100mL beaker, stir magnetically at room temperature for 60min, weigh 11.9g of zinc nitrate, measure 8mL of methanol, Alcohol 12mL, placed in a beaker, stirred to form a zinc nitrate solution. Slowly add the prepared zinc nitrate solution dropwise into the prepared silica sol, and continue stirring for 60 minutes to form a mixed sol. The mixed sol was placed in a vacuum oven (the vacuum degree was set to 0), and the temperature in the cavity was set to 30° C., and aged for 10 h. Then the temperature was raised to 120° C. for gel drying for 12 hours. Place the dried gel in a quartz container, then place it in a muffle furnace, turn on the heater, raise the temperature to 300°C, keep at this temperature for 120min, the heating rate is 1°C / min, and then continue to heat up to 500°C, Keep at this temperature for 120min. After roasting, let it cool down to room temperature n...

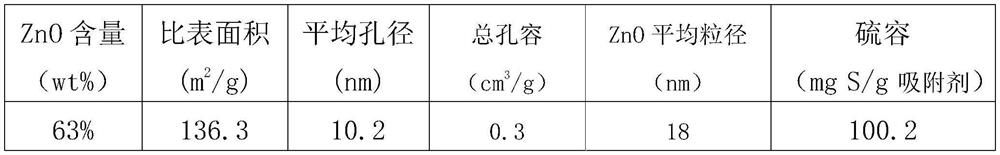

Embodiment 2

[0029] Add 9mL TEOS, 9.2% absolute ethanol, 1.5mL deionized water, 0.5mL dilute nitric acid (4mol / L) into a 100mL beaker, stir magnetically at room temperature for 120min, weigh 14.87g of zinc nitrate, measure 8.9mL of methanol, Diol 13.4mL, placed in a beaker, stirred to form a zinc nitrate solution. Slowly add the prepared zinc nitrate solution dropwise into the prepared silica sol, and continue stirring for 80 minutes to form a mixed sol. The mixed sol was placed in a vacuum oven (the vacuum degree was set to 0), and the temperature in the chamber was set to 30° C., and aged for 11 h. Then the temperature was raised to 120° C. for gel drying for 13 hours. Place the dried gel in a quartz container, then place it in a muffle furnace, turn on the heater, raise the temperature to 300°C, keep at this temperature for 120min, the heating rate is 1°C / min, and then continue to heat up to 500°C, Keep at this temperature for 180min. After roasting, let it cool down to room temperat...

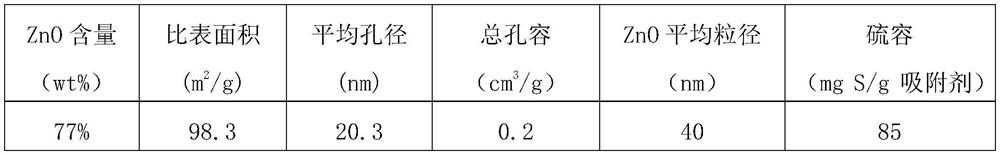

Embodiment 3

[0034] Add 9mL TEOS, 12mL absolute ethanol, 2.2mL deionized water, 0.5mL dilute hydrochloric acid (4mol / L) into a 100mL beaker, stir magnetically at room temperature for 90min, weigh 29.75g of zinc nitrate, measure 20mL of methanol, Alcohol 33mL, placed in a beaker, stirred to form a zinc nitrate solution. Slowly add the prepared zinc nitrate solution dropwise into the prepared silica sol, and continue stirring for 90 minutes to form a mixed sol. The mixed sol was placed in a vacuum oven (the vacuum degree was set to 0), and the temperature in the cavity was set to 30° C., and aged for 10 h. Then the temperature was raised to 120° C. for gel drying for 13 hours. Place the dried gel in a quartz container, then place it in a muffle furnace, turn on the heater, raise the temperature to 300°C, keep at this temperature for 90min, the heating rate is 1°C / min, and then continue to heat up to 500°C, Keep at this temperature for 180min. After roasting, let it cool down to room tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com