Processing process of smelting of silicon carbide

A processing technology, silicon carbide technology, applied in the direction of silicon carbide, carbide, chemical industry, etc., can solve the problems that do not meet the requirements of social sustainable development, can not realize the recovery of heat, complex operation of silicon carbide smelting process, etc., to achieve Good energy saving and environmental protection effect, low production cost, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

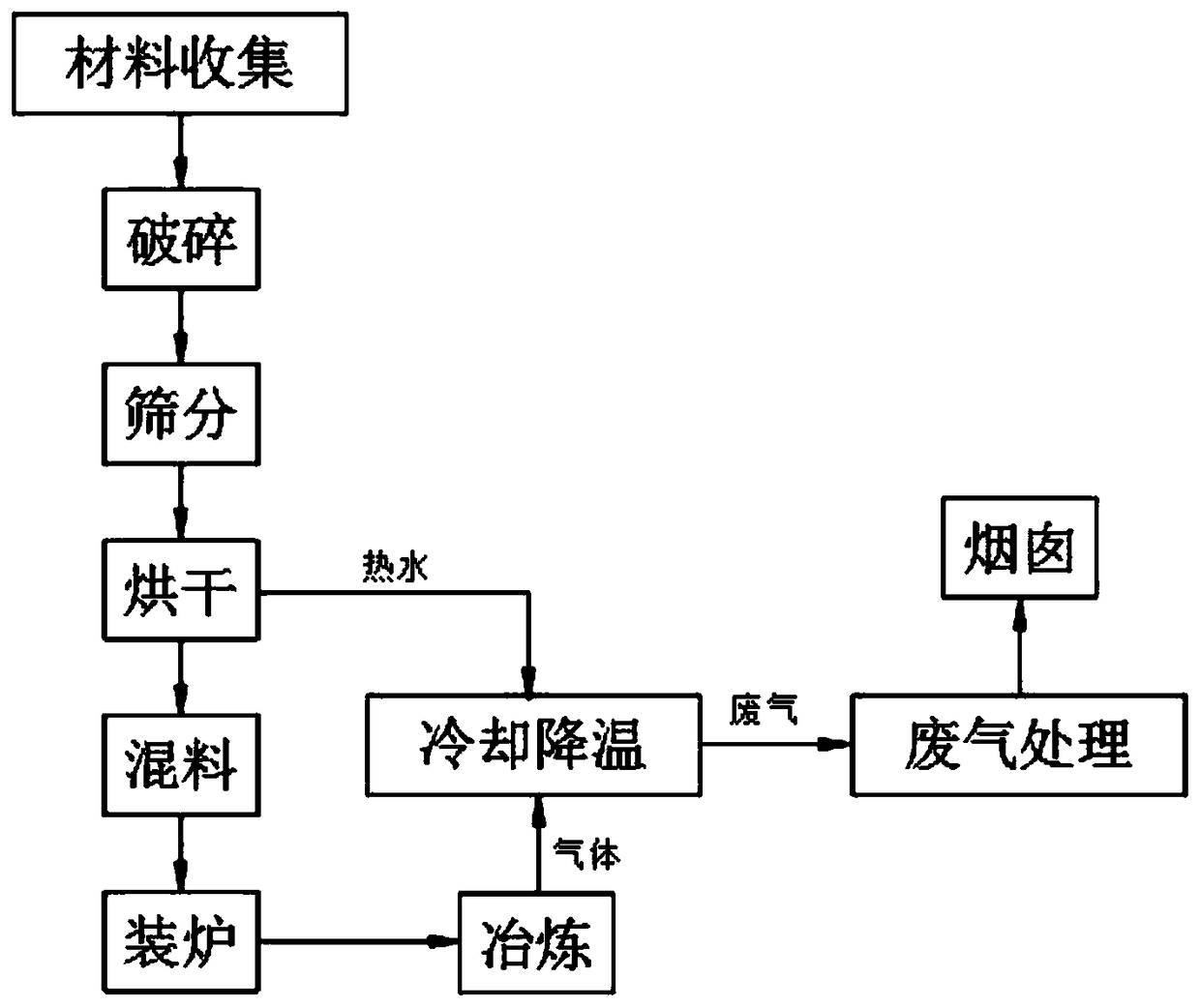

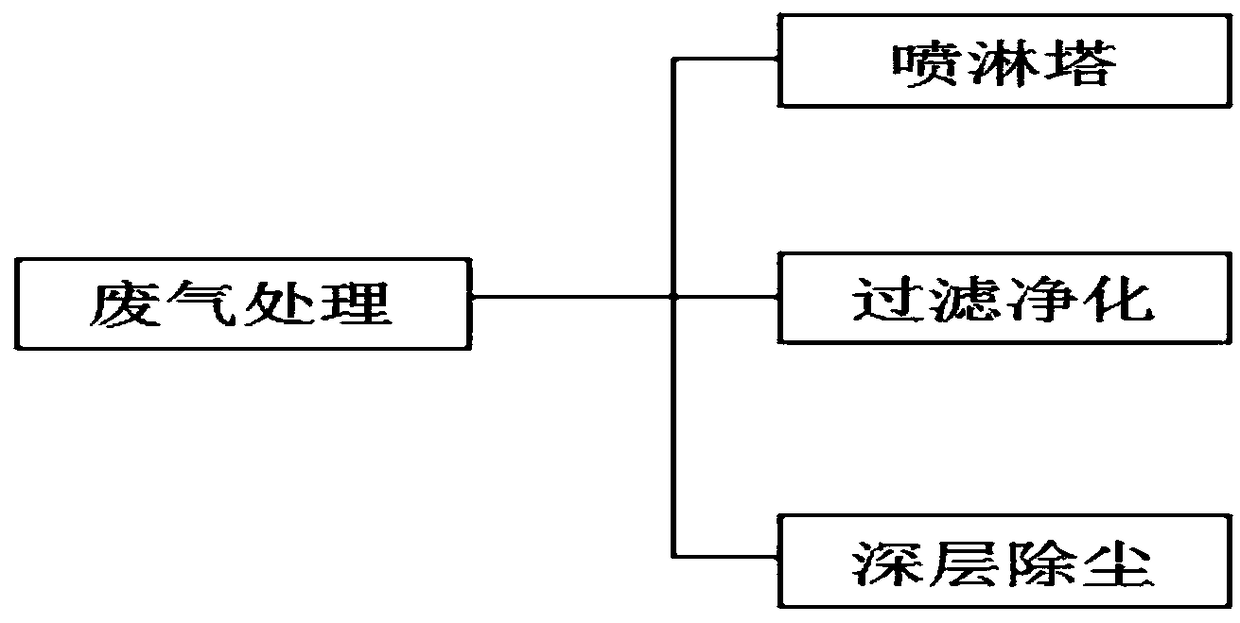

[0028] see Figure 1-2 , in an embodiment of the present invention, a silicon carbide smelting processing technology, the specific processing technology is the following steps:

[0029] 1): Material collection: The main raw materials are petroleum tar and quartz sand, which are essential materials for the manufacture of silicon carbide, which provide participants in basic chemical reactions; auxiliary materials include sawdust and salt, and auxiliary materials do not directly participate in the basic reaction process. Sawdust mainly makes the material form a porous sintered body, which is convenient for the discharge of carbon monoxide during the smelting process; table salt mainly plays a role in promoting the formation of silicon carbide; recycled materials: including roasting materials, fine crystals, adhesives, thermal insulation materials, and decomposed graphite phase Old furnace core material, etc.;

[0030] 2): Crushing: The main raw material petroleum coke and recycl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com