Nickel-free hole sealing agent for aluminum alloy anode oxide film and preparation method

An anodized film, aluminum alloy technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of high temperature required for the process, increased production costs, and inability to achieve completeness, so as to avoid human body and Environmental hazards, energy saving, improved flatness and brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

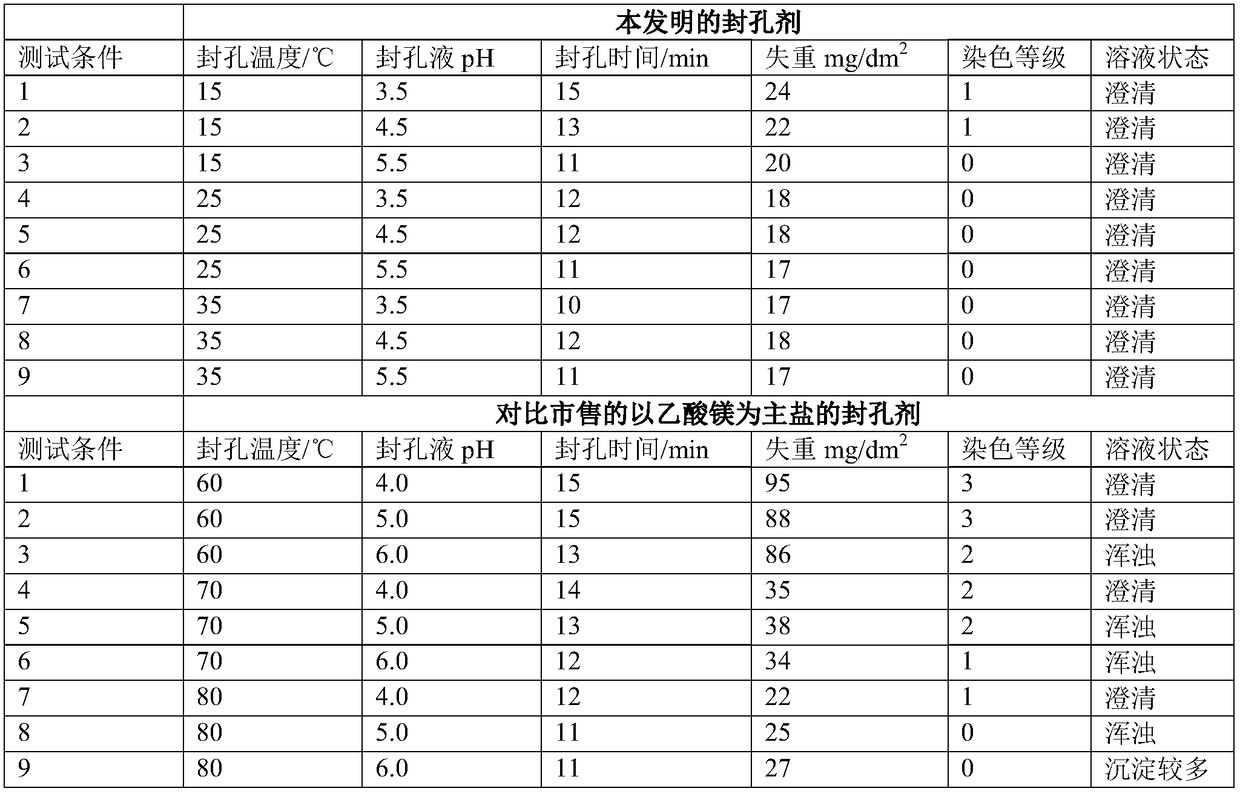

Examples

Embodiment 1

[0032] A nickel-free sealing agent for aluminum alloy anodic oxidation film, which is composed of the following raw materials in terms of mass percentage: 3.0% zinc-based main salt compound, 3.0% complexing agent, 3.0% sealing accelerator, 10.0% Stabilizer, 12.5% gray suppressant brightener, 68.5% water.

[0033] The preparation method of the above-mentioned aluminum alloy anodized film nickel-free sealing agent is:

[0034] Weigh zinc nitrate: 30 parts, sodium gluconate: 30 parts, ammonium bifluoride: 30 parts, polyvinylpyrrolidone: 25 parts, polyethylene glycol: 100 parts, polydimethylsiloxane: 100 parts respectively by weight percentage . Water: 685 parts. Add the above-mentioned raw materials in order in all parts of the water under stirring. After one raw material is completely dissolved, add the next raw material. After adding all the raw materials, stir until the solution is clear and transparent.

Embodiment 2

[0036] A nickel-free sealing agent for aluminum alloy anodized film, which is composed of the following raw materials in terms of mass percentage: 3.0% zinc-based main salt compound, 4.0% complexing agent, 4.0% sealing accelerator, 9.0% Stabilizer, 11.0% gray suppression brightener, 69.0% water.

[0037] The preparation method of the above-mentioned aluminum alloy anodized film nickel-free sealing agent is:

[0038] Weigh respectively zinc nitrate: 30 parts, EDTA: 40 parts, potassium fluoride: 40 parts, polyvinylpyrrolidone: 20 parts, polyethylene glycol: 90 parts, polydimethylsiloxane: 90 parts, Water: 690 parts, add the above raw materials in order in all parts of the water under stirring, add the next raw material after one raw material is completely dissolved, and stir until the solution is clear and transparent.

Embodiment 3

[0040] A nickel-free sealing agent for aluminum alloy anodized film, which is composed of the following raw materials in terms of mass percentage: 6.0% zinc-based main salt compound, 3.0% complexing agent, 3.0% sealing accelerator, 4.0% Stabilizer, 5.0% gray suppression brightener, 79.0% water.

[0041] The preparation method of the above-mentioned aluminum alloy anodized film nickel-free sealing agent is:

[0042] Weigh zinc lactate: 60 parts, sodium oxalate: 30 parts, sodium thiosulfate: 30 parts, polyvinylpyrrolidone: 20 parts, Tween 80: 40 parts, polydimethylsiloxane: 30 parts by weight percentage . Water: 790 parts. Add the above-mentioned raw materials in order in all parts of the water under stirring. After one raw material is completely dissolved, add the next raw material. After adding all the raw materials, stir until the solution is clear and transparent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com