A kind of synthetic method of sodium phenytoin

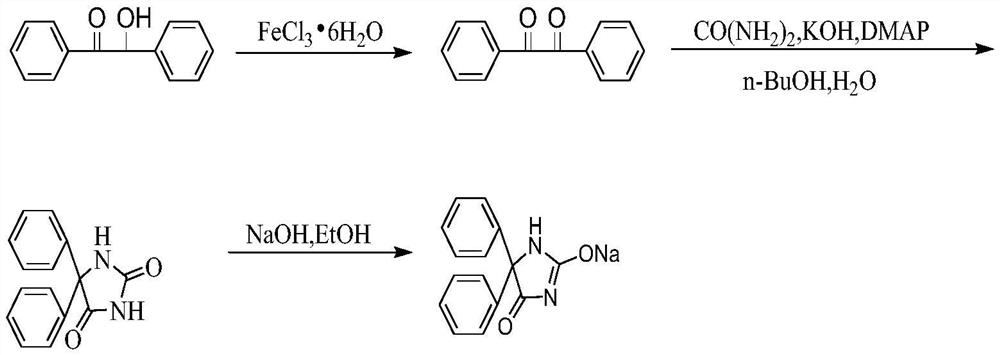

A synthesis method and a technology of phenytoin sodium, applied in the field of biomedicine, can solve the problems of the impurity diphenylacetylene diurea being difficult to remove, long reaction time, many side reactions, etc., and achieve obvious competitive advantages, shorten the reaction time, and save a lot of costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Oxidation reaction: weigh 2.18g of benzoin, 5.4g of ferric trichloride hexahydrate, measure 13mL of glacial acetic acid, and 5.2mL of distilled water, pour them into a three-necked flask in turn, stir, and heat under reflux for 50min, and the reaction stops heating completely; The reaction solution was poured into a 100 mL beaker, 40 mL of distilled water was added, and an ice-salt bath was performed for 15 min. After the yellow needle-like crystals were precipitated, suction filtration was performed, and the filter cake was washed with distilled water for several times to obtain 2.14 g of bibenzoyl;

[0033] Condensation reaction: add 2.14g bibenzoyl, 1.80g urea, 2.13g potassium hydroxide, 0.06g 4-dimethylaminopyridine, 22mL n-butanol, 22mL distilled water to a 250mL three-necked round-bottom flask, stir magnetically at 115 The reaction was refluxed for 30 min, and the reaction was completely stopped heating; the reaction solution was cooled to room temperature, poured ...

Embodiment 2

[0036] Oxidation reaction: weigh 8.67g benzoin, 24.5g ferric trichloride hexahydrate, measure 50mL glacial acetic acid and 22mL distilled water, pour them into a three-necked flask in turn, start stirring, and heat under reflux for 52min, the reaction stops heating completely; after cooling, The reaction solution was poured into a 500 mL beaker, 173 mL of distilled water was added, and after an ice-salt bath for 16 min, yellow needle-like crystals were precipitated, suction filtered, and the filter cake was washed with distilled water for several times to obtain 8.5 g of bibenzoyl;

[0037] Condensation reaction: add 8.5g bibenzoyl, 7.4g urea, 9g potassium hydroxide, 0.26g 4-dimethylaminopyridine, 71mL n-butanol, 85mL distilled water to a 250mL three-necked round bottom flask, stir magnetically, heat at 118°C and reflux 35min, stop heating after the reaction is complete. The reaction solution was cooled to room temperature, poured into a 500 mL separatory funnel, extracted thr...

Embodiment 3

[0040] Oxidation reaction: weigh 10.71g of benzoin, 28g of ferric trichloride hexahydrate, weigh 64mL of glacial acetic acid, and 25mL of distilled water, pour them into a three-necked flask in turn, start stirring, and heat under reflux for 55min, the reaction is completely stopped heating; after cooling, the reaction The liquid was poured into a 500 mL beaker, 210 mL of distilled water was added, and after an ice-salt bath for 18 min, yellow needle-like crystals were precipitated, suction filtered, and the filter cake was washed with distilled water for several times to obtain bibenzoyl;

[0041] Condensation reaction: add 10.5g bibenzoyl, 9g urea, 10.64g potassium hydroxide, 0.305g 4-dimethylaminopyridine, 105mL n-butanol, 125mL distilled water to a 500mL three-necked round bottom flask, stir magnetically, heat to 119 The temperature was refluxed for 40 min, and the heating was stopped after the reaction was completed. The reaction solution was cooled to room temperature, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com