A kind of geomembrane for soil remediation engineering and preparation method thereof

A technology of soil remediation and geomembrane, applied in the field of soil remediation, can solve the problems of poor stability, antistatic and flame retardant performance, weak puncture resistance, corrosion resistance and tear resistance, antistatic and flame retardant performance Excellent and other issues, to achieve the effects of low equipment dependence, improved mechanical properties and weather resistance, excellent antistatic and flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

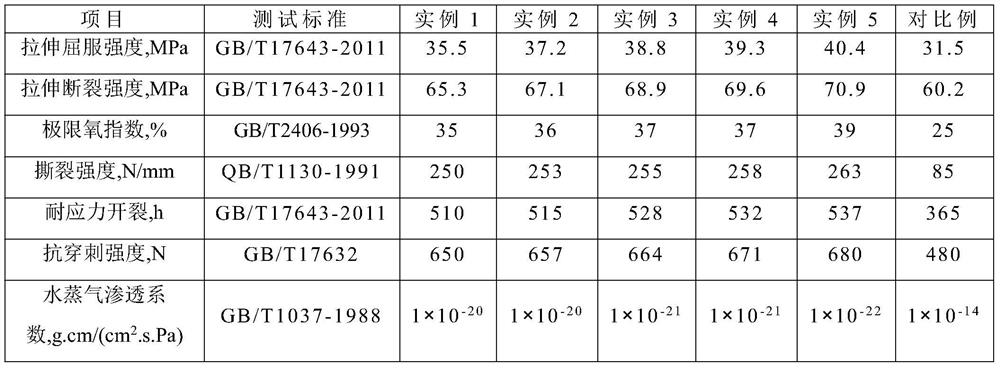

Examples

Embodiment 1

[0028] A preparation method for a geomembrane for soil restoration engineering, comprising the steps of:

[0029] Ⅰ Preparation of ferrocene-based pentafluorophenyl adamantyl copolymer: 1000g of 2,3,4,5,6-pentafluorostyrene, 1000g of 2-ethyl-2-adamantyl methacrylate, 1-(2-allyl-3,6-dihydroxyphenyl) ethane-1-one 100g, vinyl ferrocene 200g, vinyl phosphoric acid 100g, acrylonitrile 1000g were dissolved in dimethyl sulfoxide 6000g, And add 20g of azobisisobutyronitrile thereinto, stir and react at 70°C in a nitrogen atmosphere for 6 hours, then precipitate in water, wash the precipitated polymer 4 times with ethanol, and place it in a vacuum oven at 80°C Dried to constant weight, obtained based on ferrocene pentafluorophenyl adamantyl copolymer;

[0030] Ⅱ Surface modified steel fiber / nano-boron fiber composite filler: mix 100g of steel fiber and 200g of nano-boron fiber evenly, then disperse in 1000g of acetonitrile, and then add tetradecyldimethyl (3-trimethoxysilane Propyl)a...

Embodiment 2

[0034]A preparation method for a geomembrane for soil restoration engineering, comprising the steps of:

[0035] Ⅰ Preparation of ferrocene-based pentafluorophenyl adamantyl copolymer: 1000g of 2,3,4,5,6-pentafluorostyrene, 1000g of 2-ethyl-2-adamantyl methacrylate, 1-(2-allyl-3,6-dihydroxyphenyl) ethane-1-one 100g, vinyl ferrocene 200g, vinyl phosphoric acid 100g, acrylonitrile 1000g dissolved in N-methylpyrrolidone 7500g , and 25 g of azobisisoheptanonitrile was added thereto, stirred and reacted for 6.5 hours in a helium atmosphere at 73° C., and then precipitated in water. The precipitated polymer was washed with ethanol for 5 times, and then placed in a vacuum oven at 83° C. Dried to constant weight in the box, obtained based on ferrocene pentafluorophenyl adamantyl copolymer;

[0036] Ⅱ Surface modified steel fiber / nano-boron fiber composite filler: Mix 100g of steel fiber and 200g of nano-boron fiber evenly, then disperse in 1100g of chloroform, and then add tetradecyl...

Embodiment 3

[0040] A preparation method for a geomembrane for soil restoration engineering, comprising the steps of:

[0041] Ⅰ Preparation of ferrocene-based pentafluorophenyl adamantyl copolymer: 1000g of 2,3,4,5,6-pentafluorostyrene, 1000g of 2-ethyl-2-adamantyl methacrylate, 1-(2-allyl-3,6-dihydroxyphenyl) ethane-1-one 100g, vinyl ferrocene 200g, vinyl phosphoric acid 100g, acrylonitrile 1000g dissolved in N,N-dimethyl In 8500g of formamide, 30g of azobisisoheptanonitrile was added thereto, stirred and reacted for 6.5 hours at 73°C in a neon atmosphere, and then precipitated in water, and the precipitated polymer was washed 5 times with ethanol, and then placed in 83 ℃ in a vacuum drying oven to a constant weight to obtain a ferrocene-based pentafluorophenyl adamantyl copolymer;

[0042] Ⅱ Surface modified steel fiber / nano-boron fiber composite filler: Mix 100g of steel fiber and 200g of nano-boron fiber evenly, then disperse in 1300g of acetone, and then add tetradecyldimethyl (3-tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com