Multi-strain fermentation process for improving flavor of soy sauce

A multi-strain fermentation and process technology, applied in the direction of bacteria, micrococcus, yeast-containing food ingredients used in food preparation, etc., can solve the problems affecting the quality of sauce mash, slow absorption of salt water by koji, and less aroma substances, etc. The effect of improving the utilization rate of raw materials and the conversion rate of amino acid nitrogen, the use of less strains, and the high utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

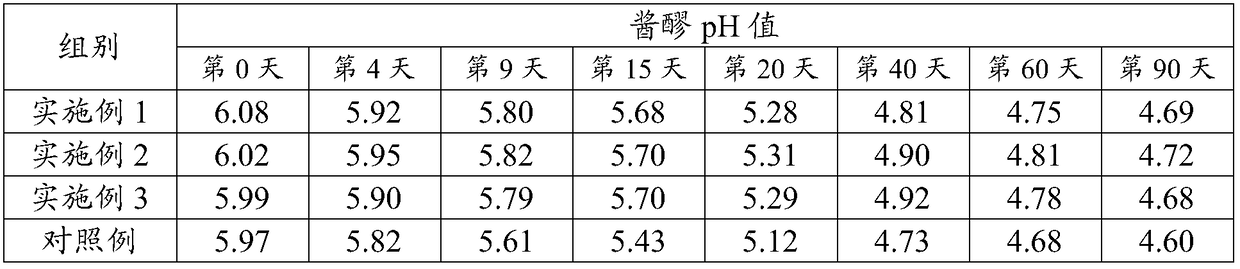

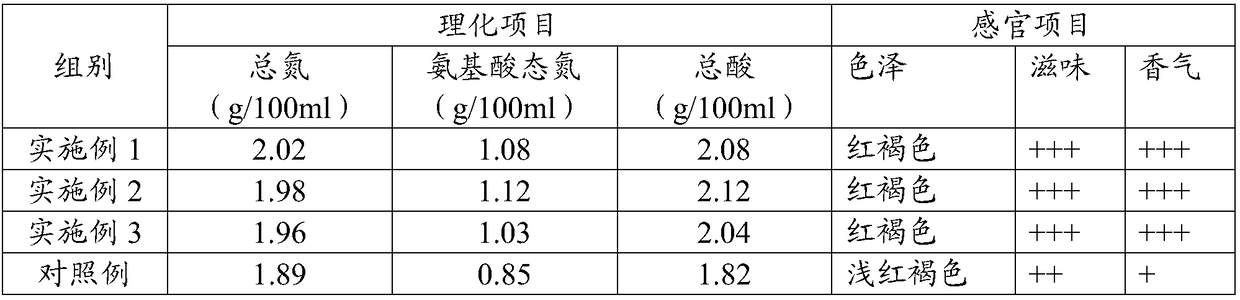

Examples

Embodiment 1

[0047] The multi-strain fermentation process for improving the flavor of soy sauce comprises the following steps:

[0048] 1), make soy sauce mature koji material by conventional soy sauce koji making method;

[0049] 2) Mix the mature koji with soy sauce and 15Bé brine in a weight ratio of 1:1.2 to obtain moromi, and stir until the materials are evenly mixed;

[0050] 3), pump the mixed material in step 2) into a closed fermenter, raise the temperature of the mixed material to 42°C, let it stand for 5 days, and measure the protease activity in the material to be 3210U / g; Bacteria were evenly inoculated into the mash for pre-fermentation. During the fermentation period, nitrogen gas was introduced for intermittent stirring for 20 minutes, aeration and stirring every 5 days. The temperature of the mash was controlled at 10°C; the pre-fermentation time was 18 days, and the nitrogen pressure was 0.5 MPa; the amount of Weissella added to each gram of moromi is 4 × 10 5 CFU / g.

...

Embodiment 2

[0055] The multi-strain fermentation process for improving the flavor of soy sauce comprises the following steps:

[0056] 1), make soy sauce mature koji material by conventional soy sauce koji making method;

[0057] 2) Mix the mature koji with soy sauce and 18Bé brine in a weight ratio of 1:1.4 to obtain moromi, and stir until the materials are evenly mixed;

[0058] 3), pump the mixed material in step 2) into a closed fermenter, raise the temperature of the mixed material to 43°C, let it stand for 6 days, and measure the protease activity in the material to be 3400U / g; Bacteria were uniformly inoculated into the soy mash for pre-fermentation. During the fermentation period, nitrogen gas was introduced for intermittent stirring for 25 minutes, aeration and stirring every 6 days. The temperature of the mash was controlled at 13°C; the pre-fermentation time was 15 days, and the nitrogen pressure was 0.7 MPa; the amount of Weissella added to each gram of moromi is 4 × 10 6 CF...

Embodiment 3

[0063] The multi-strain fermentation process for improving the flavor of soy sauce comprises the following steps:

[0064] 1), make soy sauce mature koji material by conventional soy sauce koji making method;

[0065] 2), the soy sauce mature koji material and 20Bé brine are mixed in a weight ratio of 1:1.5 to obtain moromi, and fully stirred until the materials are evenly mixed;

[0066] 3), pump the mixed material in step 2) into a closed fermenter, raise the temperature of the mixed material to 45°C, let it stand for 7 days, and measure the protease activity in the material to be 3050U / g; Bacteria were uniformly inoculated into the soy mash for pre-fermentation. During the fermentation period, nitrogen gas was introduced for intermittent stirring for 30 minutes, and aeration and stirring was performed every 7 days. The temperature of the mash was controlled at 15°C; the pre-fermentation time was 20 days, and the nitrogen pressure was 1MPa ; Weissella is 4.5 × 10 per gram o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com