Ultrahigh-molecular weight ethylene polymer powder and molded article using the ultrahigh-molecular weight ethylene polymer powder

An ultra-high molecular weight, ethylene-based technology, applied in the direction of single-component polyolefin artificial filaments, electrical components, electrochemical generators, etc., can solve the problems of resin extrusion molding processing difficulties, high molecular weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

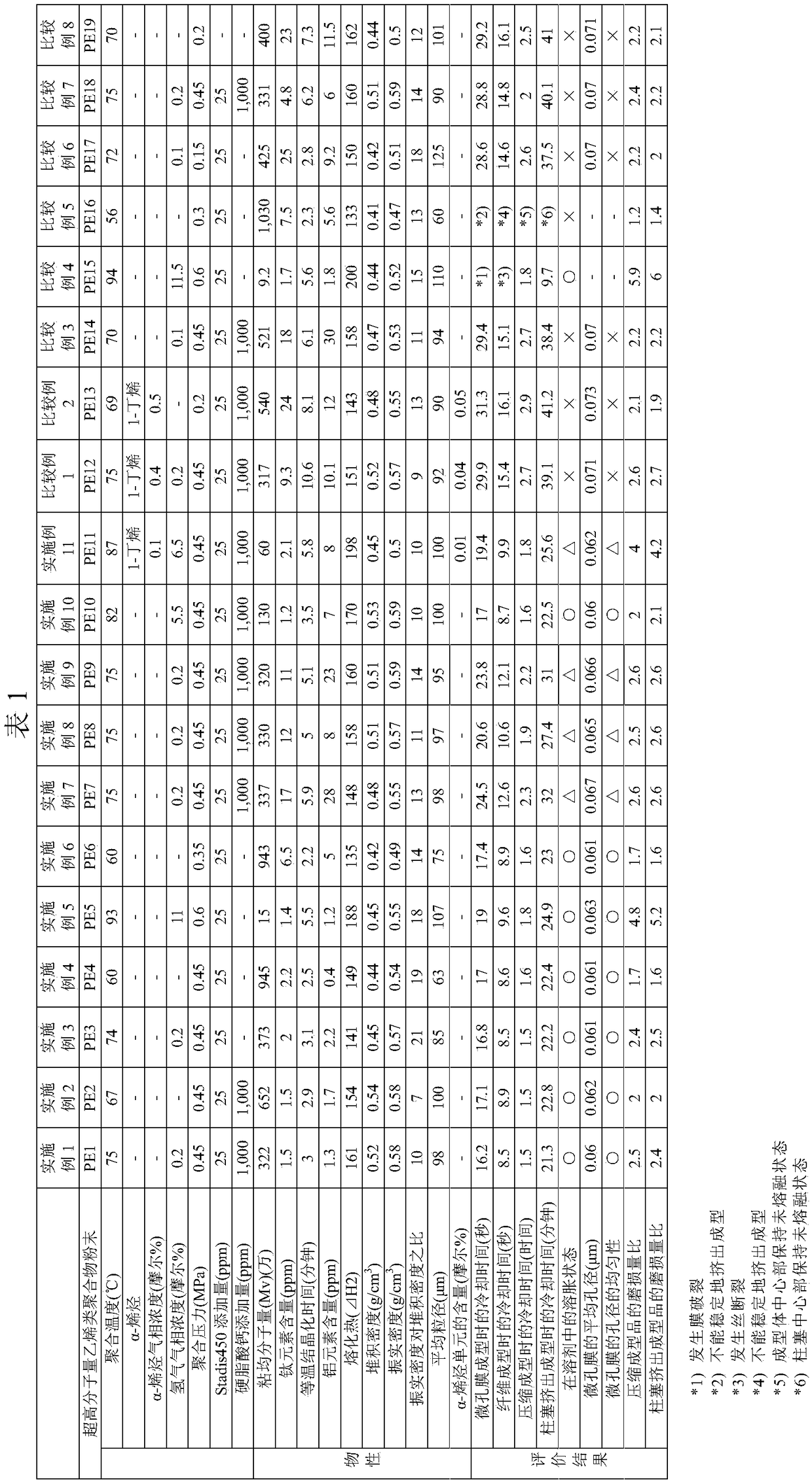

Examples

Embodiment

[0110] Hereinafter, the present invention will be described in more detail by way of examples and comparative examples, but the present invention is not limited to the following examples at all.

[0111] [Measurement method and conditions]

[0112] (1) Viscosity average molecular weight (Mv)

[0113] The viscosity-average molecular weight of the ultrahigh molecular weight ethylene-based polymer powder was determined by the method shown below in accordance with ISO1628-3 (2010). First, weigh 20 mg of ultra-high molecular weight ethylene-based polymer powder in a melting tube, replace the melting tube with nitrogen, and then add 20 mL of decahydronaphthalene (add 2,6-di-tert-butyl-4-methanol at 1 g / L Decalin based phenol) was stirred at 150° C. for 2 hours to dissolve the ultra-high molecular weight ethylene-based polymer powder. For this solution, the fall time (ts) between the marked lines was measured using a Cannon-Fenske viscometer (manufactured by Shibata Scientific Inst...

Synthetic example 1

[0182] [Catalyst Synthesis Example 1: Preparation of Solid Catalyst Component [A]]

[0183] (1) Synthesis of (A-1) vector

[0184] Into an 8 L stainless steel autoclave fully replaced with nitrogen and equipped with 8 stirring blades, 1000 mL of a hexane solution of 2 mol / L hydroxytrichlorosilane was added dropwise over 4 hours while stirring at 65°C and 120 rpm. Composed of the formula AlMg 5 (C 4 h 9 ) 11 (OC 4 h 9 ) 2 2,550 mL of a hexane solution of the indicated organomagnesium compound (corresponding to 2.68 mol of magnesium), was further stirred at 65° C. and 120 rpm for 1 hour, and the reaction was continued. After the reaction was completed, the supernatant was removed, and washed 4 times with 1800 mL of hexane. As a result of analyzing this solid ((A-1) support), the magnesium contained in 1 g of solid was 8.31 mmol.

[0185] (2) Preparation of solid catalyst component [A]

[0186] While stirring at 10°C, 110 mL of 1 mol / L titanium tetrachloride hexane solu...

Embodiment 1

[0189] (Example 1: PE1)

[0190] Hexane, ethylene, hydrogen, catalyst, and Stadis 450 (manufactured by The Associated Octel Company) were continuously supplied to a Bessel-type 300L polymerization reactor equipped with a stirring device. The polymerization temperature was maintained at 75°C using jacket cooling. Hexane was supplied at 55 L / hour. As the catalyst, a mixture of triisobutylaluminum and diisobutylaluminum hydride and a solid catalyst component [A] were used as cocatalyst components. The solid catalyst component [A] was added to the polymerizer at a rate of 0.7 g / hour, and a mixture of triisobutylaluminum and diisobutylaluminum hydride was added to the polymerizer at a rate of 9 mmol / hour. In addition, the solid catalyst component [A] and the mixture of triisobutylaluminum and diisobutylaluminum hydride were added in equal amounts each time so that the rate may become 5 L / hour. Similarly, Stadis450 was added so that the density|concentration of Stadis450 with res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com