Halosulfuron methyl-containing herbicide composition and application thereof

A technology of chlorpyrazosulfuron-methyl and herbicidal composition, which is applied in the field of herbicidal composition containing chlorpyrazosulfuron-methyl, can solve problems such as poor control effect, achieve the effects of reducing costs, timely control, and improving crop quality and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

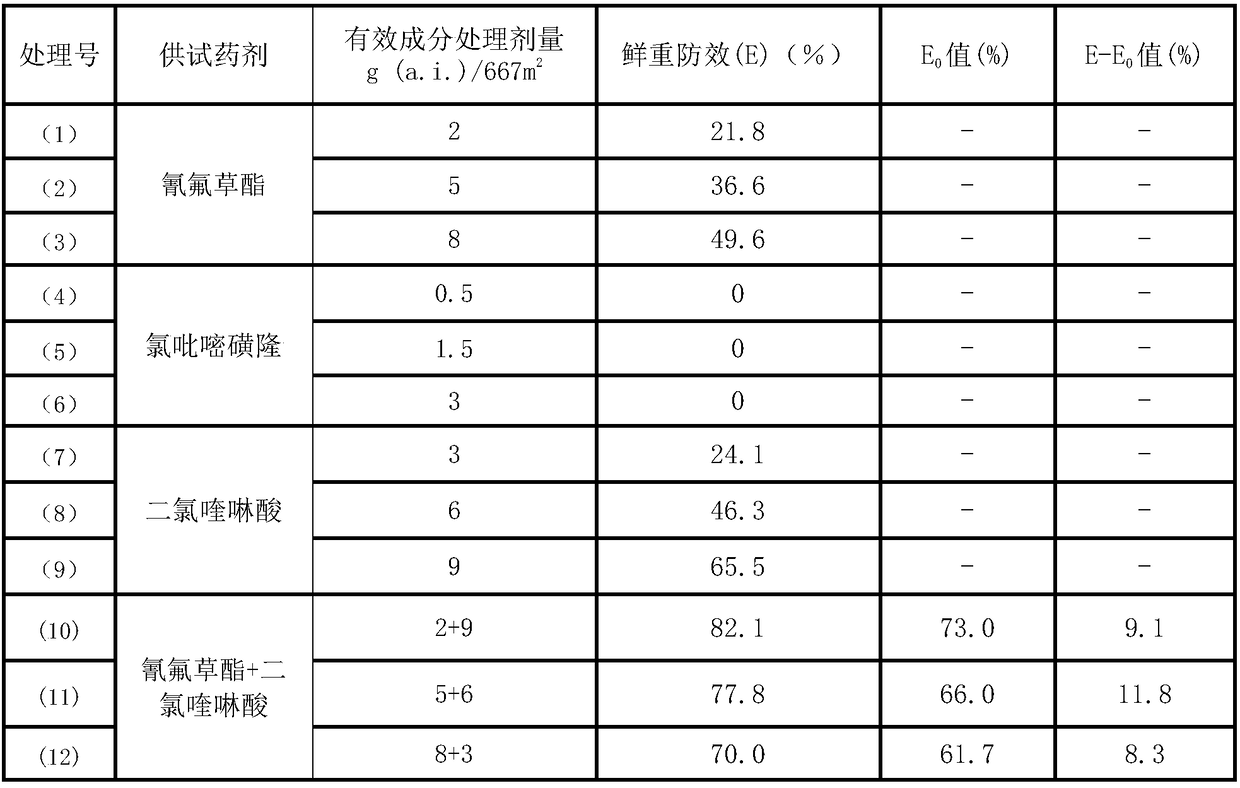

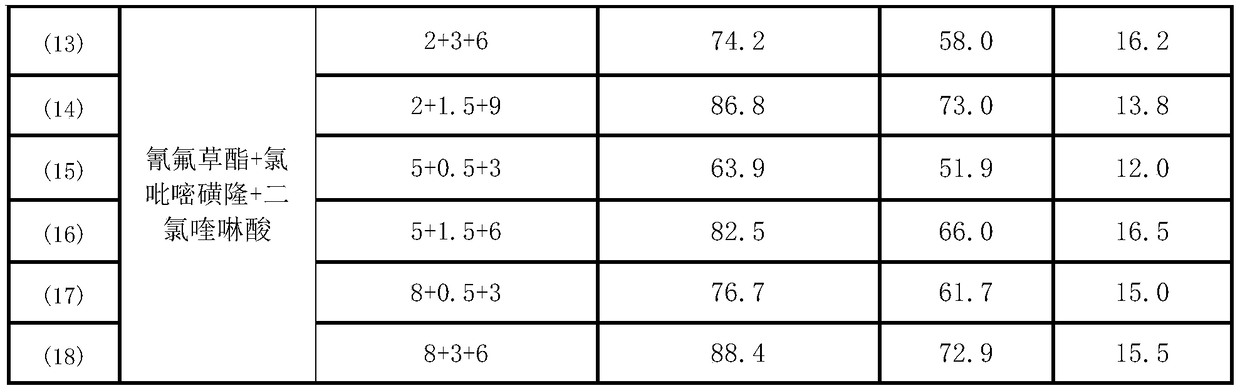

Method used

Image

Examples

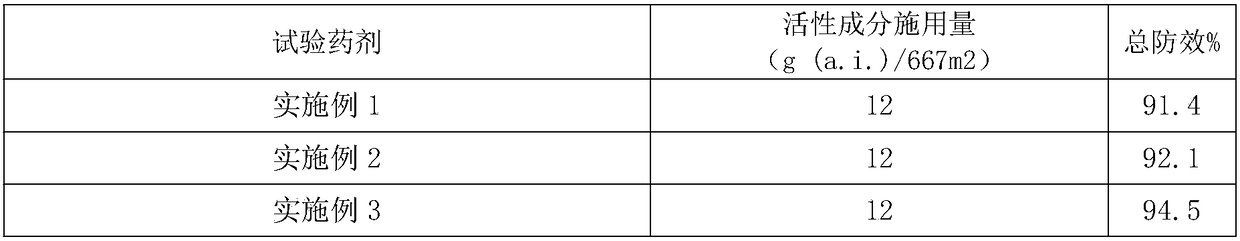

Embodiment 1

[0021] 25wt% water dispersible granules

[0022] The formula is composed of: 10wt% of cyhalofop-ethyl, 3wt% of clopyrazosulfuron-methyl, 12wt% of quinclorac, 8wt% of sodium methylnaphthalenesulfonate formaldehyde condensate, 3wt% of polycarboxylate, and 2wt% of urea , xanthan gum 1wt%, kaolin supplemented to 100wt%.

[0023] The preparation method is as follows: after all the materials are mixed uniformly, pulverized by an airflow mill, mixed uniformly again, and then a certain amount of water is added to knead the mixture, extruded and granulated, and dried and sieved to obtain the water-dispersible granules.

Embodiment 2

[0025] 14% dispersible oil suspension concentrate

[0026] The formula is composed of: 5wt% of cyhalofop-ethyl, 3wt% of clopyrazosulfuron-methyl, 6wt% of quinclorac, 4wt% of castor oil polyoxyethylene ether, 6wt% of nonylphenol polyoxyethylene ether, triphenylethyl ether Base phenol polyoxyethylene ether phosphate 3wt%, bentonite 2%, soybean oil supplemented to 100%.

[0027] The preparation method is as follows: put the active ingredient, emulsifier, dispersant and dispersion medium into the stirring tank, after fully stirring, pump it into a high-speed shearing machine for high-speed shearing, and then pump it into a sand mill for full sanding, After the sand mill is qualified, add a thickener and stir evenly to obtain a dispersible oil suspension.

Embodiment 3

[0029] 20% EC

[0030] The formula is composed of: 10wt% of cyhalofop-ethyl, 2wt% of chlorpyrazosulfuron-methyl, 8wt% of quinclorac, 4wt% of tristyrylphenol polyoxyethylene ether, 5wt% of agricultural milk, sorbitan ester 4wt%, make up to 100% with xylene.

[0031] The preparation method is as follows: put all the materials into the batching kettle, stir and dissolve until completely transparent, and transfer to the storage tank for filling after passing the test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com