Preparation method and application of a xonotlite and sodium-doped xonotlite and regeneration thereof

A technology of xonotlite and sodium chloride, which is applied in the field of preparation of xonotlite and sodium-doped xonotlite, which can solve the problems of limited reserves of natural xonotlite, achieve excellent adsorption capacity, and improve adsorption performance , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Preparation of xonotlite:

[0043] (1) Collect discarded egg shells, wash, remove the film, dry, crush, place in a muffle furnace for calcination at 800-900°C for 3.5-5 hours, then cool to room temperature in a desiccator to obtain CaO powder, pass through a 200-mesh sieve Back sealed for use;

[0044] (2) Weigh the CaO in step (1) and place it in a beaker, add deionized water, stir and react for 20-40 minutes, and then statically age for 4-6 hours to obtain Ca(OH) 2 ;

[0045] (3) Ca(OH) obtained in step (2) 2 and SiO 2 Mix evenly with a molar ratio of Ca / Si of 1:1, put it into a conical flask, add deionized water, seal it, and sonicate for 50-70 minutes to obtain a mixed solution;

[0046] (4) Move the mixed solution prepared in step (3) into an autoclave, place it in a muffle furnace at 220-250°C for 8-10 hours, and then age it statically for 5-7 hours, then filter it with suction, pickle, Wash with water and dry at 65-75°C for 3-4 hours to obtain xonotlite, den...

Embodiment 2

[0048] Preparation of sodium xonotlite:

[0049] (1) Collect discarded egg shells, wash, remove the film, dry, crush, place in a muffle furnace for calcination at 800-900°C for 3.5-5 hours, then cool to room temperature in a desiccator to obtain CaO powder, pass through a 200-mesh sieve Back sealed for use;

[0050] (2) Weigh the CaO in step (1) and place it in a beaker, add deionized water, stir and react for 20-40 minutes, and then statically age for 4-6 hours to obtain Ca(OH) 2 ;

[0051] (3) Ca(OH) obtained in step (2) 2 and SiO 2 Mix evenly with a molar ratio of Ca / Si of 1:1 and put it into an Erlenmeyer flask, add deionized water and sodium chloride with a weight-to-solid-liquid ratio of 30:1 in sequence, seal it, and sonicate for 50-70 minutes to obtain a mixed solution;

[0052] (4) Move the mixed solution prepared in step (3) into an autoclave, place it in a muffle furnace at 220-250°C for 8-10 hours, and then age it statically for 5-7 hours, then filter it with s...

Embodiment 3

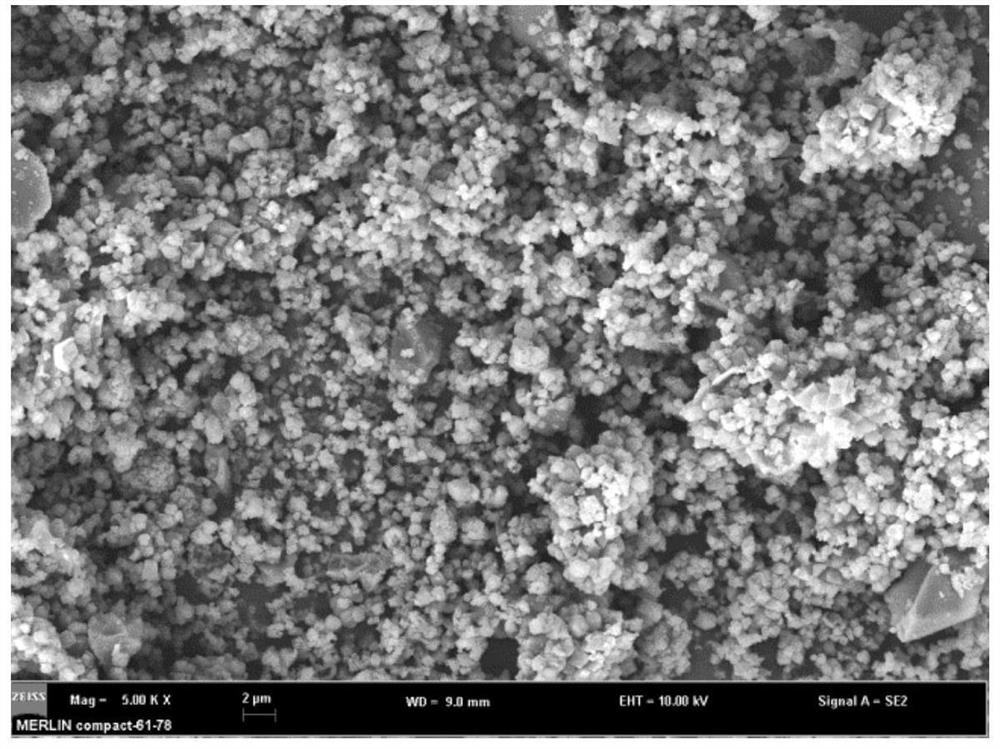

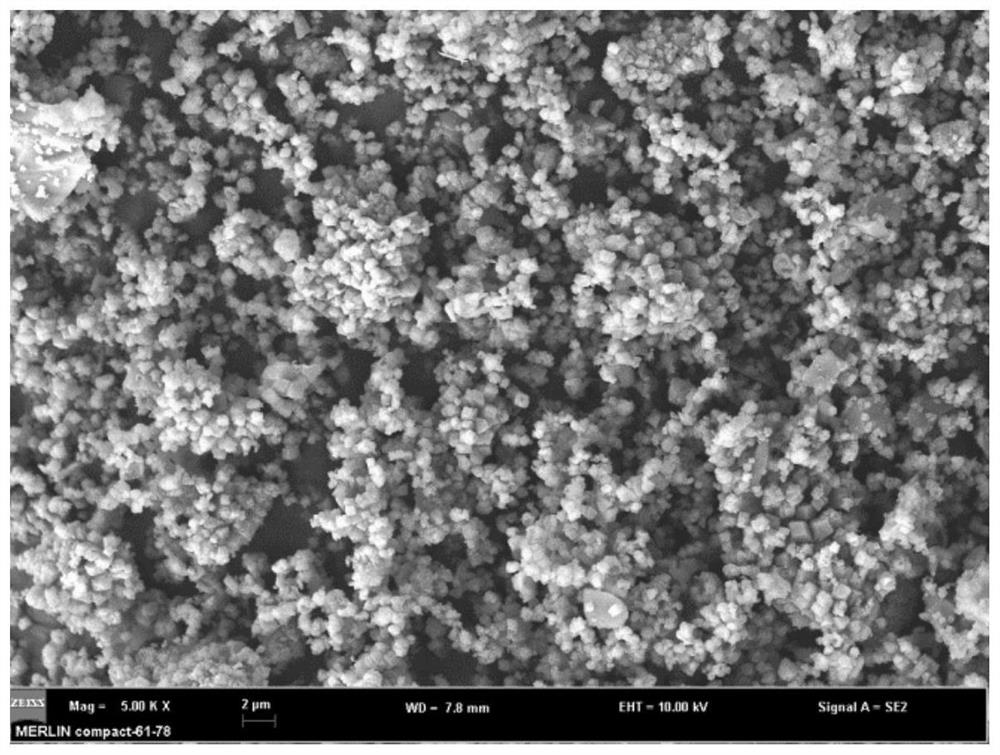

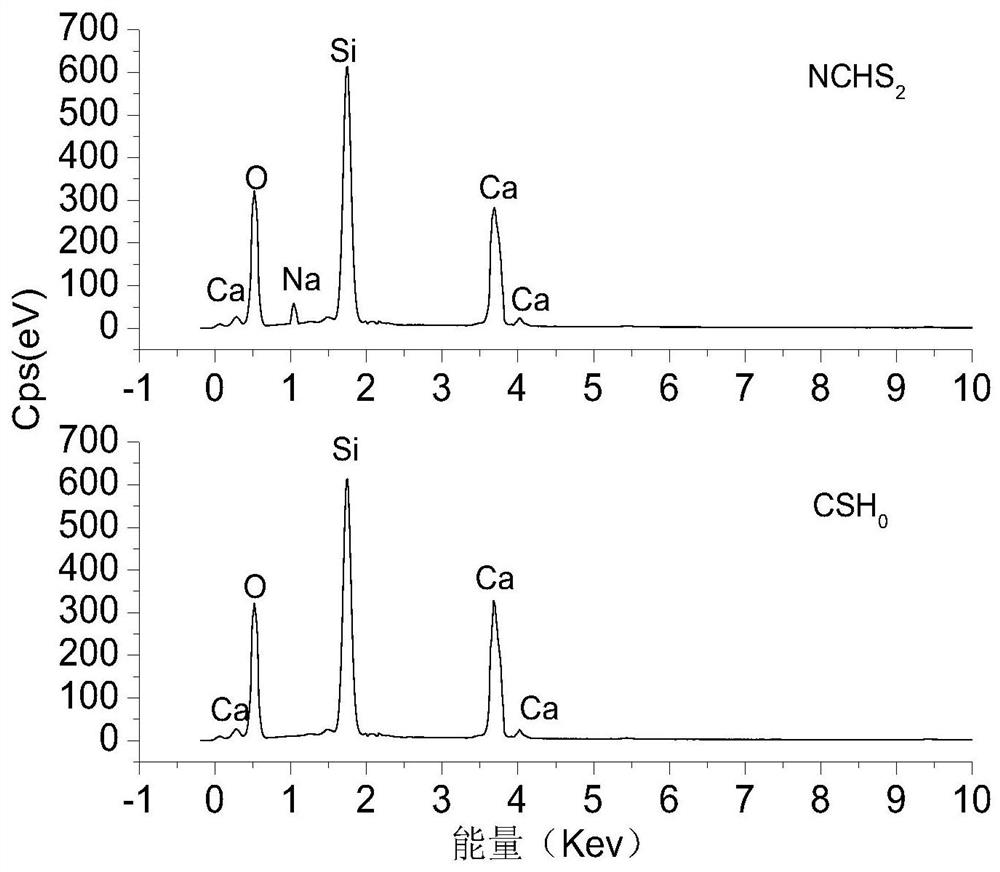

[0055] CSH 0 and NCSH performance measurements:

[0056] 1. Determination of physical properties of materials

[0057] CSH was analyzed by nitrogen adsorption method (BET). 0 、NCSH 1 、NCSH 2 、NCSH 3 and NCSH 4 The specific surface area and pore structure of several samples were characterized, and the results are shown in Table 1.

[0058] Table 1 BET determination data of different types of xonotlite

[0059]

[0060] As can be seen from Table 1, sodium-doped xonotlite (NCSH 1 、NCSH 2 、NCSH 3 and NCSH 4 ) specific surface area is larger than that of pure xonotlite, indicating that xonotlite can properly increase its specific surface area and improve the inter-particle pore structure by adding sodium. When the amount of sodium is added too much, the specific surface area of xonotlite will not increase but will decrease. The reason is that the calcium of xonotlite is saturated by sodium replacement and is limited. At the same time, too much sodium will also prope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com