High-dielectricity three-phase polypropylene composite material, preparation method and application thereof

A composite material, polypropylene technology, applied in the field of polymers, can solve the problems such as the inability to effectively improve the compatibility of carbon nanotubes and polypropylene, and achieve the effect of improving the agglomeration problem, good strength and toughness, and good physical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

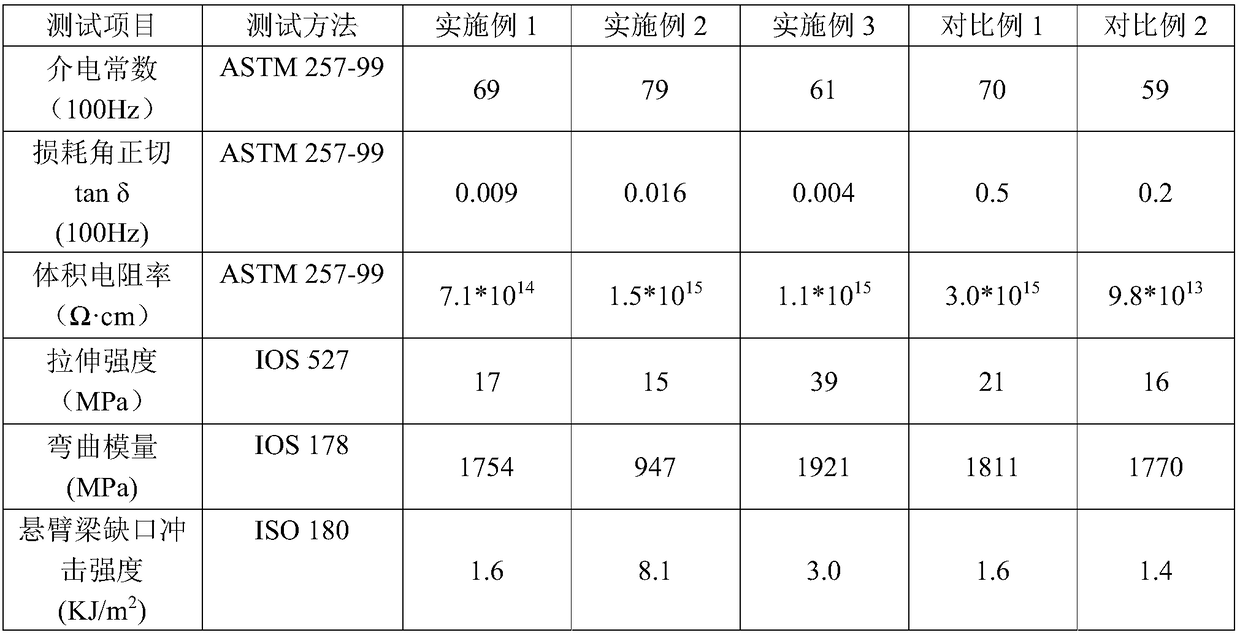

Examples

preparation example 1

[0045] 20 g of carbon nanotubes, 200 mL of concentrated sulfuric acid and 60 g of potassium permanganate were sequentially added to the reaction kettle, and after stirring at room temperature for 0.5 hours, the temperature was raised to 100° C. and stirred for 12 hours. After the reaction was completed, it was cooled to room temperature, an equal volume of deionized water was added to the reaction solution and suction filtration was carried out. After the filtered product was washed and filtered for three times, the filtered product was added to 200 ml of hydrazine hydrate and stirred for 1 hour, and the reaction solution was suction filtered. , washed three times and dried to obtain carbon oxide nanotubes. In the high-temperature reaction kettle, 10 g of carbon oxide nanotubes, 4-bromobutyryl chloride and 10 times the amount of 4-bromobutyryl chloride and 10 times the amount of carbon oxide nanotubes were added successively, and the reaction was carried out at 80 ° C for 12 A...

preparation example 2

[0047] The preparation method of the modified nano-ceramic: the surface of the copper-calcium titanate nano-ceramic particles is treated by atmospheric cold pressure plasma, the plasma gas is argon, the gas flow rate is 10L / min, the power is 600W, the treatment voltage is 4000V, and the treatment distance is 1cm. Processing time 5min. The treated nano-ceramic 500g was added to the reactor containing 600g of 1-dodecylsulfonyl chloride, 1000g of potassium carbonate, 2L of N,N-dimethylformamide, cooled to room temperature after 8 hours of reaction at 60°C and pumped. Filtering, washing the suction filtration product three times, suction filtration each three times, and drying to obtain the modified nano-ceramic.

preparation example 3

[0049] The preparation method of the modified nano-ceramic: the surface of the copper-calcium titanate nano-ceramic wire is treated by atmospheric cold pressure plasma. Processing time 5min. The treated nano-ceramic 500g was added to the reactor containing 600g of 1-dodecylsulfonyl chloride, 1000g of potassium carbonate, 2L of N,N-dimethylformamide, cooled to room temperature after 8 hours of reaction at 60°C and pumped. Filtering, washing the suction filtration product three times, suction filtration each three times, and drying to obtain the modified nano-ceramic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com