Detection method for concentration of demulsifying agent in crude oil

A detection method and demulsifier technology, which are applied in the direction of material analysis, measurement device, and test sample preparation through observation of the influence of chemical indicators, and can solve the problems of unstable measurement methods, difficult spectral analysis, and interference with quantitative analysis. issues such as low standard deviation, wide coverage and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] In this embodiment, the Yanyi Joint Station is selected as the test target, in order to provide a detection method for the concentration of polyoxyethylene in crude oil, and the detection method includes the following steps:

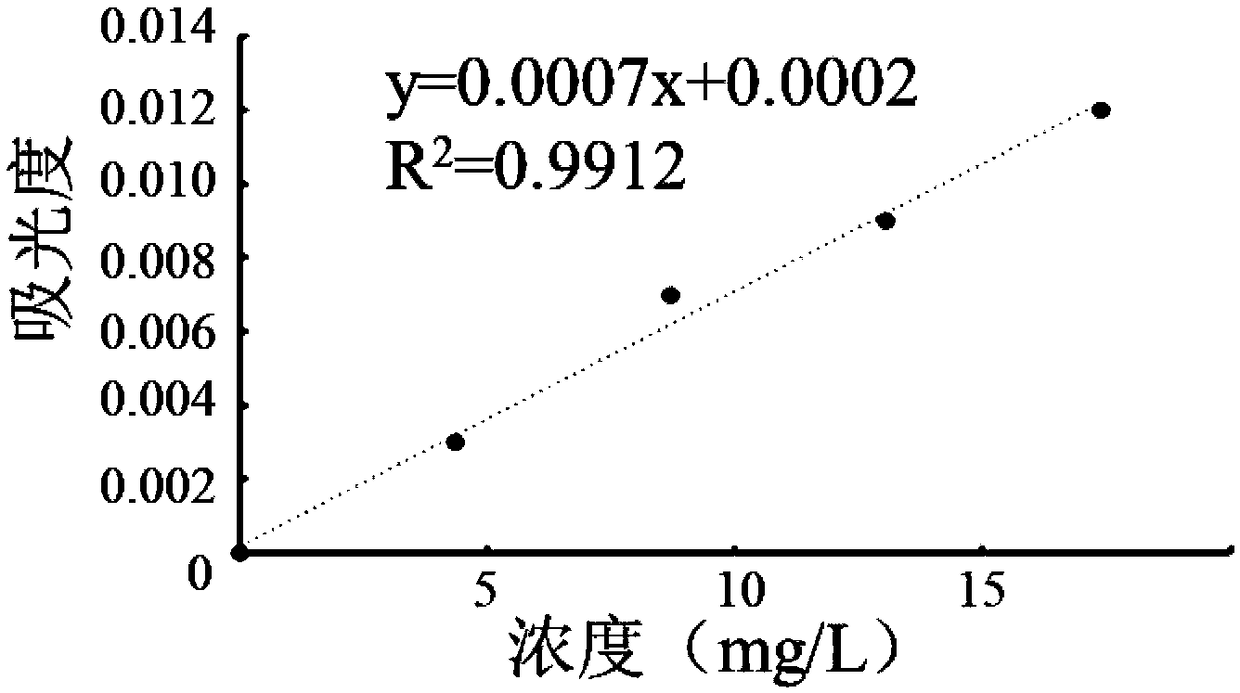

[0089] (1) Take by weighing 3g cobalt nitrate, 20g ammonium thiocyanate and 20g potassium chloride and dissolve in distilled water, stir evenly, transfer to 100mL volumetric flask, constant volume with distilled water, shake up, obtain cobalt thiocyanate salt solution; Use demulsifier to prepare standard solutions with concentration gradients of 0 mg / L, 5 mg / L, 10 mg / L, 15 mg / L, and 20 mg / L, and add 10 mL of dichloromethane or trichloromethane with a concentration of 99.5% to extract for 10 min. Then add the cobalt thiocyanate solution that the step (1) of 5mL obtains and develop color 10min at 25 DEG C, benefit ultraviolet spectrophotometer to measure standard solution organic layer by ultraviolet spectrophotometry when test temperature is 25 DEG ...

Embodiment 2

[0101] This embodiment selects any combination station as the test target, and is to provide a detection method for polyoxyethylene group concentration in crude oil, and the detection method includes the following steps:

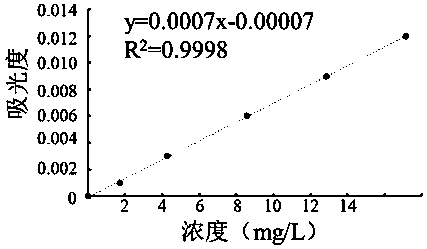

[0102] (1) Take by weighing 3g cobalt nitrate, 20g ammonium thiocyanate and 20g potassium chloride and dissolve in distilled water, stir evenly, transfer to 100mL volumetric flask, constant volume with distilled water, shake up, obtain cobalt thiocyanate salt solution; Use a demulsifier to prepare standard solutions with concentration gradients of 2mg / L, 4mg / L, 9mg / L, 13mg / L, and 18mg / L, and add a volume of 10mL of dichloromethane or trichloromethane with a concentration of 99.5% for 10min. Then add the cobalt thiocyanate solution that the step (1) of 5mL obtains and develop color 10min at 25 DEG C, benefit ultraviolet spectrophotometer to measure standard solution organic layer by ultraviolet spectrophotometry when test temperature is 25 DEG C at a wavelengt...

Embodiment 3

[0110] The present embodiment chooses the Ma-Yi joint station as the test target, is to provide a kind of detection method of polyoxyethylene group concentration in crude oil, and described detection method comprises the following steps:

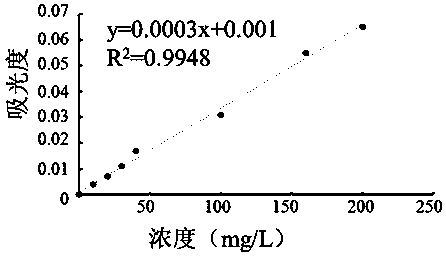

[0111] (1) Take by weighing 3g cobalt nitrate, 20g ammonium thiocyanate and 20g potassium chloride and dissolve in distilled water, stir evenly, transfer to 100mL volumetric flask, constant volume with distilled water, shake up, obtain cobalt thiocyanate salt solution; Use demulsifier to prepare standard solutions with concentration gradients of 12mg / L, 25mg / L, 35mg / L, 50mg / L, 100mg / L, 170mg / L, and 220mg / L, and add a volume of 10mL of 99.5% dichloro Extract with methane or chloroform for 10min, then add the cobalt thiocyanate salt solution obtained in step (1) with a volume of 5mL and develop color for 10min at 25°C, which is beneficial for the ultraviolet spectrophotometer to pass the ultraviolet spectrophotometric method when the test tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com