Fe3O4@bacterial cellulose/graphene oxide composite aerogel as well as preparation method and application thereof

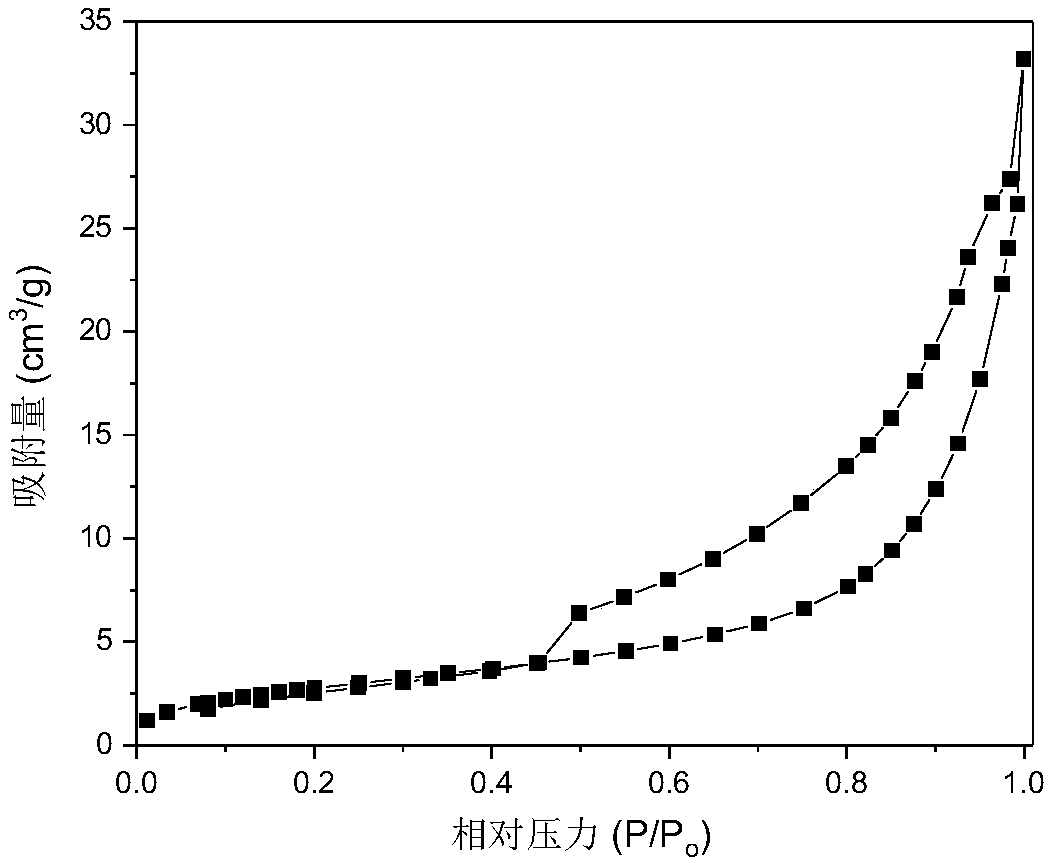

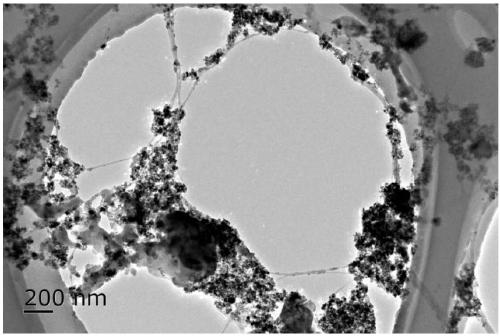

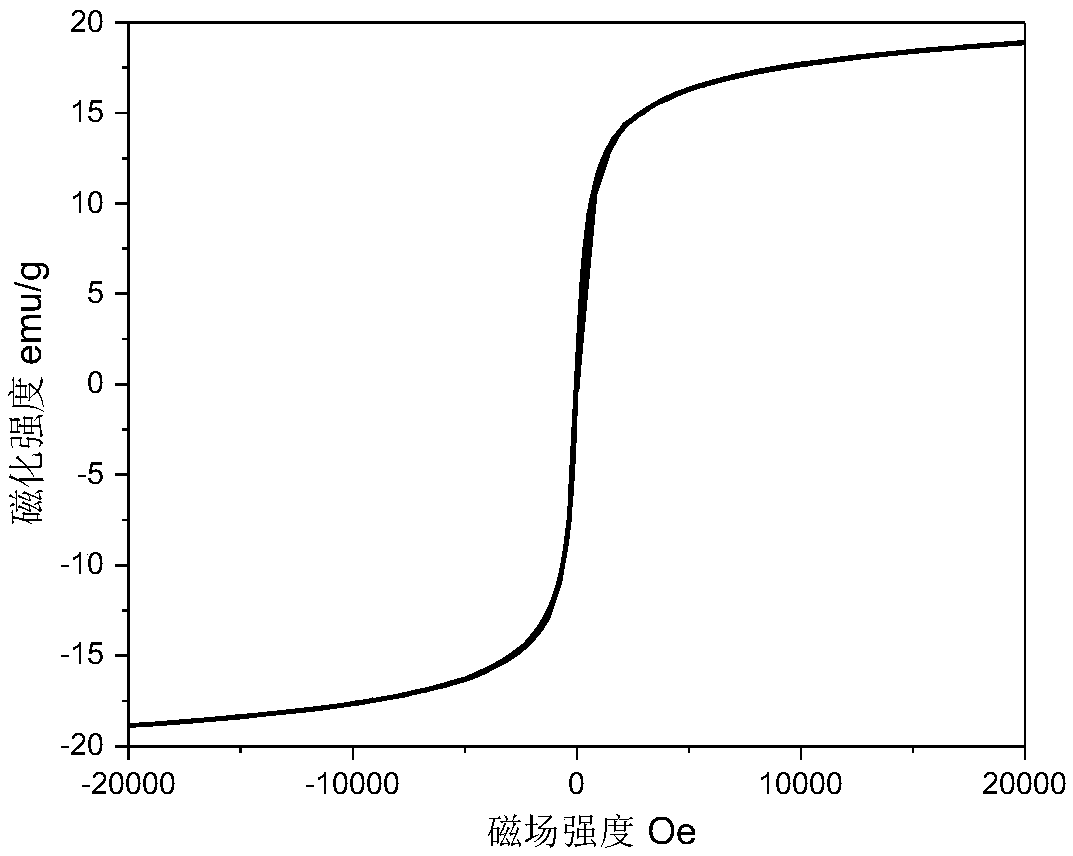

A composite technology of bacterial cellulose and graphene, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve problems such as high cost, complicated separation process, and unfavorable quantitative production, etc. Achieve the effect of low cost, complex separation process and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Desugaring treatment of bacterial cellulose: take 100g of bacterial cellulose, wash it three times with tap water, wash it once with deionized water, 4mol / L NaOH solution, soak at 75°C for 6h. Wash with tap water after soaking to pH=7.

[0048] Preparation of graphene oxide aqueous solution: Mix 0.1 g of multilayer graphene oxide (available from Suzhou Hengqiu Technology Co., Ltd.) with 100 mL of deionized water, and ultrasonically disperse at 45° C. for 1 h to prepare a graphene oxide solution.

[0049] Preparation of bacterial cellulose / graphene oxide composite hydrogel: Stir the desugared bacterial cellulose into a slurry, add 400mL graphene oxide aqueous solution to the bacterial cellulose slurry, stir evenly for 20min, 30°C, Under 80Hz, ultrasonic vibration for 2h, and after standing for 1d, the bacterial cellulose / graphene oxide composite hydrogel material was obtained.

[0050] In bacterial cellulose / graphene oxide composite hydrogel material, add 5.56g FeSO 4 ...

Embodiment 2

[0060] Desugaring treatment of bacterial cellulose: take 100g of bacterial cellulose and wash it three times with tap water and once with deionized water, 4mol / L NaOH solution, soaking time at 70°C for 2h. Wash with tap water after soaking to pH=9.

[0061] Preparation of graphene oxide aqueous solution: Mix 0.4 g of multilayer graphene oxide with 100 mL of deionized water, and ultrasonically disperse at 60° C. for 2 h to prepare a graphene oxide solution.

[0062] Preparation of bacterial cellulose / graphene oxide composite hydrogel: Stir the desugared bacterial cellulose into a slurry, add 50mL graphene oxide aqueous solution to the bacterial cellulose slurry, stir evenly for 10min, 60°C, Under 60Hz, ultrasonic vibration for 1h, and after standing for 3d, the bacterial cellulose / graphene oxide composite hydrogel material was obtained.

[0063] In bacterial cellulose / graphene oxide composite hydrogel material, add 5.56g FeSO 4 ·7H 2 O and 2.71 g FeCl 3 ·6H 2 O(FeSO 4 ·7H...

Embodiment 3

[0073] Desugaring treatment of bacterial cellulose: take 100g of bacterial cellulose, wash it three times with tap water, wash it once with deionized water, and soak it in 2.5mol / L NaOH solution at 60°C for 1h. Wash with tap water after soaking to pH=10.

[0074] Preparation of graphene oxide aqueous solution: Mix 0.01 g of multilayer graphene oxide with 100 mL of deionized water, and ultrasonically disperse at 30° C. for 3 h to prepare a graphene oxide solution.

[0075] Preparation of bacterial cellulose / graphene oxide composite hydrogel: Stir the desugared bacterial cellulose into a slurry, add 200mL graphene oxide aqueous solution to the bacterial cellulose slurry, stir evenly for 30min, and heat at 45°C After ultrasonic vibration for 3 hours and standing for 2 days, bacterial cellulose / graphene oxide composite hydrogel material was obtained

[0076] In bacterial cellulose / graphene oxide composite hydrogel material, add 0.556g FeSO 4 ·7H 2 O and 21.64 g FeCl 3 ·6H 2 O...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com