Method for preparing graphene under coupling effect of electric field and ultrasonic field

A technology of ultrasonic field and graphene, applied in the field of carbon nanomaterials, can solve the problems of danger and high energy consumption, and achieve the effect of low cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

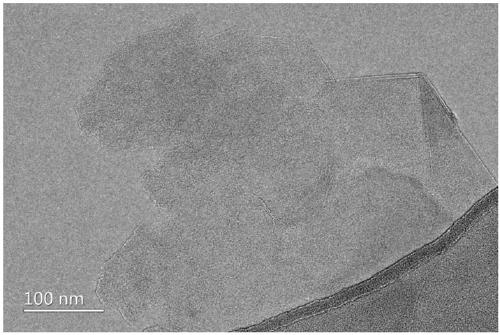

Image

Examples

Embodiment 1

[0018] In this example, see figure 1 , a method for preparing graphene under the coupled action of an electric field and an ultrasonic field, comprising the steps of:

[0019] a. Dissolve 7.584g of triethylmethylammonium chloride in 500mL of deionized water to prepare an electrolyte with a concentration of 0.1mol / L;

[0020] b. the electrolytic solution prepared in the step a is placed in the electrolytic cell, and two graphite sheets with a purity of 99.9% are used as electrodes, inserted in parallel in the electrolytic solution, so that the distance between the two graphite electrodes is 3cm, and the assembled electrochemical Reaction device, and use graphite electrode as carbon source raw material;

[0021] c. put the electrolytic cell in the step b into the ultrasonic pool, set the reaction voltage to 10V, set the frequency to 0.1Hz, and the ultrasonic power to 30W, turn on the electric field and the ultrasonic field at the same time, and apply the electric field and the ...

Embodiment 2

[0026] This embodiment is basically the same as Embodiment 1, especially in that:

[0027] In this embodiment, a method for preparing graphene under the coupling effect of an electric field and an ultrasonic field comprises the following steps:

[0028] a. Dissolve 5.48g of tetramethylammonium chloride in 500mL of deionized water to prepare an electrolyte with a concentration of 0.1mol / L;

[0029] b. the electrolytic solution prepared in the step a is placed in the electrolytic cell, and two graphite sheets with a purity of 99.9% are used as electrodes, inserted in parallel in the electrolytic solution, so that the distance between the two graphite electrodes is 3cm, and the assembled electrochemical Reaction device, and use graphite electrode as carbon source raw material;

[0030] c. put the electrolytic cell in the step b into the ultrasonic pool, set the reaction voltage to 10V, set the frequency to 0.1Hz, and the ultrasonic power to 30W, turn on the electric field and th...

Embodiment 3

[0035] This embodiment is basically the same as the previous embodiment, and the special features are:

[0036] In this embodiment, a method for preparing graphene under the coupling effect of an electric field and an ultrasonic field comprises the following steps:

[0037] a. Dissolve 9.285g of benzyltrimethylammonium chloride in 500mL of deionized water to prepare an electrolyte with a concentration of 0.1mol / L;

[0038] b. the electrolytic solution prepared in the step a is placed in the electrolytic cell, and two graphite sheets with a purity of 99.9% are used as electrodes, inserted in parallel in the electrolytic solution, so that the distance between the two graphite electrodes is 3cm, and the assembled electrochemical Reaction device, and use graphite electrode as carbon source raw material;

[0039] c. put the electrolytic cell in the step b into the ultrasonic pool, set the reaction voltage to 10V, set the frequency to 0.1Hz, and the ultrasonic power to 30W, turn on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| carrier mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com