Method for sectional regulation and control for continuous strain culture

A technology for cultivating strains and segmented regulation, applied in microorganism-based methods, biochemical equipment and methods, bacteria, etc., can solve problems such as restricting downstream applications, fluctuations in fermentation broth components, and changes in bacterial activity. The effect of improving the utilization rate of raw materials, simplifying the production process, and high batch stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

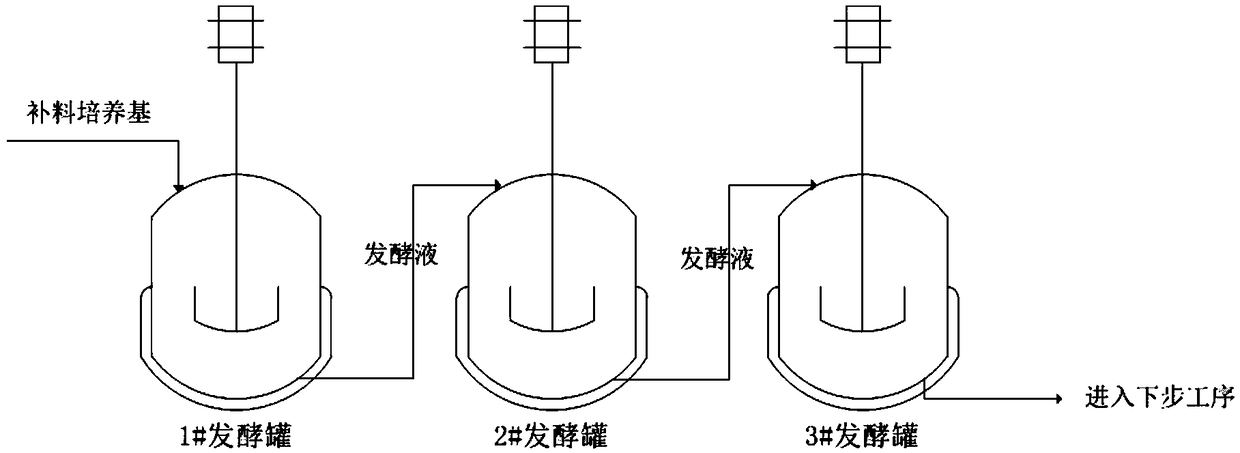

[0037] Using Pseudomonas aeruginosa as the strain, it was inoculated into three 3L fermenters connected in series after activation and shake flask culture, with a liquid volume of 70%. The fermentation medium contains glycerol 60g / L, yeast extract 10g / L, potassium dihydrogen sulfate 1g / L, disodium hydrogen phosphate 1g / L, ferrous sulfate 0.2g / L, magnesium sulfate 0.1g / L, and calcium chloride 0.1g / L, sodium chloride 0.1g / L, defoamer 1%. The fermentation temperature was controlled to 35°C, the pH of the fermentation broth was 7, the aeration volume of the fermentation broth was 1.0 vvm, and the stirring speed was 300 rpm, and stage I fermentation was carried out. After 20h, enter the second stage, and continuously add fresh feed medium to the 1# fermentor at a rate of 8mL / L / h. The glycerol content in the medium is increased to 72g / L, other components remain unchanged, and the aeration rate is 2.0 vvm, stirring speed 500rpm, fed fermentation for a total of 10h; then enters stage ...

Embodiment 2

[0039] Using Pseudomonas putida as the strain, it was inoculated into three 3L fermenters connected in series after activation and shake flask culture, with a liquid volume of 70%. The fermentation medium contains glucose 20g / L, rapeseed oil 20g / L, peptone 7g / L, sodium nitrate 8g / L, potassium dihydrogen sulfate 1g / L, disodium hydrogen phosphate 1g / L, ferrous sulfate 0.2g / L, magnesium sulfate 0.1g / L, calcium chloride 0.1g / L, sodium chloride 0.1g / L, defoamer 3%. The fermentation temperature was controlled to 30°C, the pH of the fermentation broth was 8, the aeration rate of the fermentation broth was 2.0 vvm, and the stirring speed was 600 rpm, and stage I fermentation was carried out. After 50h, enter the second stage, and continuously add fresh feed medium to the 1# fermentor at a rate of 16mL / L / h. The glucose and rapeseed oil content in the medium is increased to 30g / L and 30g / L, respectively. Other components remain unchanged, the aeration volume is 3.0vvm, the stirring spe...

Embodiment 3

[0041] Using Pseudomonas aeruginosa as the strain, it was inoculated into three 7L fermenters connected in series after activation and shake flask culture, with a liquid volume of 70%. The fermentation medium contains glycerol 30g / L, cottonseed oil 50g / L, yeast powder 2g / L, ammonium sulfate 3g / L, potassium dihydrogen sulfate 1g / L, disodium hydrogen phosphate 1g / L, and ferrous sulfate 0.2g / L, magnesium sulfate 0.1g / L, calcium chloride 0.1g / L, sodium chloride 0.1g / L, defoamer 2%. The fermentation temperature was controlled to 32°C, the pH of the fermentation broth was 7.5, the aeration volume of the fermentation broth was 1.5 vvm, and the stirring speed was 500 rpm, and stage I fermentation was carried out. After 30h, enter the second stage, and continuously add fresh feed medium to the 1# fermentor at a rate of 12mL / L / h. The glycerin and cottonseed oil content in the medium are increased to 54g / L and 90g / L, respectively. The composition is unchanged, the aeration rate is 2.5vv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com