Preparation method of functional cellulose aerogel composite material loaded with TiO2 nanoparticles

A technology of cellulose airgel and nanofibers, which is applied in the direction of airgel preparation, separation methods, chemical instruments and methods, etc., and can solve the problems of easily damaged cellulose nanofiber crosslinking, poor mechanical stability, and limited application effects, etc. problem, achieve the effect of reducing cracking, enhancing compression performance, and achieving thorough treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] CNFs-NH 2 Preparation of:

[0047] Take 100g of cellulose nanofiber aqueous dispersion with a mass content of 0.8% of cellulose nanofibers, add 0.6g to 1.2g 3,3'-dithiodipropionyl hydrazide, 137.8mg to 275.5mg EDC and 83mg ~165.4mg NHS, the pH of the system was adjusted to 6.5 with 0.1mol / L hydrochloric acid and did not change. After stirring at room temperature for 24 hours, the reaction was completed, and the cellulose nanofibers with amino groups were obtained by dialysis for 3-5 days.

Embodiment 2

[0049] Preparation of CNFs-CHO:

[0050] Weigh 1g to 5g of shredded filter paper and put it into a sulfuric acid solution with a mass fraction of 64%. The dispersion system is placed in an environment of 45°C for 30 to 60 minutes of hydrolysis reaction, and then washed with ultrapure water until the pH does not change to obtain fibers cellulose nanofibril crystals, dispersing cellulose nanofibril crystals in water to obtain a cellulose nanofibril crystal dispersion liquid with a mass content of 0.5-2%, adding sodium periodate to the dispersion system and oxidizing at room temperature to obtain a cellulose nanofibril crystal with two CNCs-CHO with an aldehyde group; the mass ratio of filter paper to sulfuric acid solution is 1:10, and the mass ratio of cellulose nanofibril crystals to sodium periodate is 1:2.

Embodiment 3

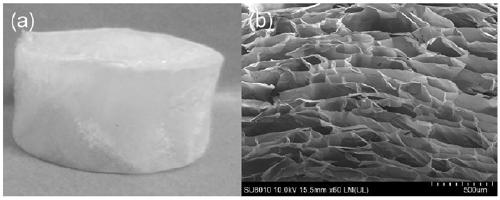

[0052] A method for preparing functional cellulose airgel, dispersing cellulose nanofibers with amino groups and CNCs-CHO with two aldehyde groups in water to obtain CNFs-NH 2 dispersion and CNFs-CHO dispersion; 5mL CNFs-NH 2 Stir mechanically with 5mL CNFs-CHO under the same mass fraction (2wt%) to make it evenly mixed. After mixing evenly, let it stand for 5 hours to increase the degree of chemical cross-linking in the airgel and age it, and then freeze-dry for 48 Hours, the functional cellulose airgel was obtained.

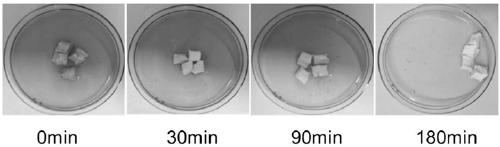

[0053] The adsorption and degradation performance of the composite material on organic pollutants in the air was determined, and the functional cellulose airgel was placed in an atmosphere of formaldehyde to make it absorb formaldehyde in the air, and the mass change of the cellulose airgel was used to characterize the gas For the adsorption capacity of the gel to formaldehyde, the mass of the functional cellulose airgel is 0.1228g, and after the adsorption ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

| Quality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com