Polyester resin with high levelling property and preparation method thereof

A technology of polyester resin and performance, applied in the field of polyester resin with high leveling performance and its preparation, can solve the problems of high cost and unsuitability for large-scale production, etc., and achieve the effect of reducing cost and high leveling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

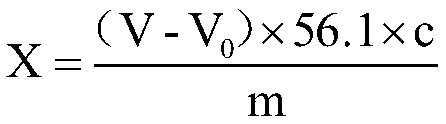

Method used

Image

Examples

Embodiment 1

[0030] The preparation of embodiment 1 polyester resin

[0031] In this embodiment, 5 repeated experiments were set up, and the amounts of raw materials are shown in Table 1 below, and the following steps were used to prepare the polyester resin.

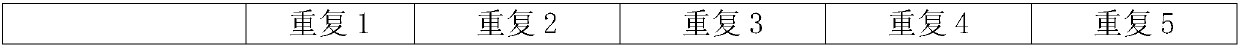

[0032] Table 1 raw material consumption

[0033] raw material

[0034] Note: Among the above raw materials, polyester chips are high molecular weight polyester chips K2100.

[0035] The preparation steps are:

[0036] (1) Accurately weigh the raw materials in Table 1, add neopentyl glycol, diethylene glycol, ethylene glycol, propylene glycol and trimethylolpropane in sequence in the reactor, and heat to a temperature of 60°C; The volume of the reaction kettle is selected according to the amount of raw materials;

[0037] (2) After the heating is completed, continue to add terephthalic acid, silicon oxide, monobutyltin oxide and polyester chips to the reaction kettle successively, heat up and continue to stir, and contin...

Embodiment 2

[0073] The preparation of embodiment 2 powder coatings

[0074] In this example, the polyester resins prepared from the five formulations in Example 1 were used to prepare powder coatings, and the amounts of raw materials are shown in Table 7 below.

[0075] Table 7 raw material consumption

[0076]

[0077] The steps of preparation are:

[0078] (1) Accurately weigh the raw materials in Table 7, add titanium dioxide, precipitant, leveling agent, brightener, benzoin and wax into the mixing tank, and mix well;

[0079] (2) Pour the mixed material into a twin-screw extruder, and melt and extrude it at 200°C;

[0080] (3) Cool the extruded material to room temperature, remove the material at the beginning of extrusion, and avoid the last remaining solid in the twin-screw extruder;

[0081] (4) Put the cooled material into a pulverizer to pulverize 3 to 4 times, and pass the pulverized material through a 500-mesh sieve;

[0082] (5) Take a part of the sieved fine pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com