Advanced treatment process of natural ester insulating oil, super-hydrophilic adsorbent and preparation method and application of super-hydrophilic adsorbent

An adsorbent and super-hydrophilic technology, which can be used in solid adsorbent liquid separation, petroleum industry, separation methods, etc., can solve the problem that it is difficult to guarantee the properties of natural ester insulating oil itself, and achieve simple performance recovery process, ensure stability, Promote Promising Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

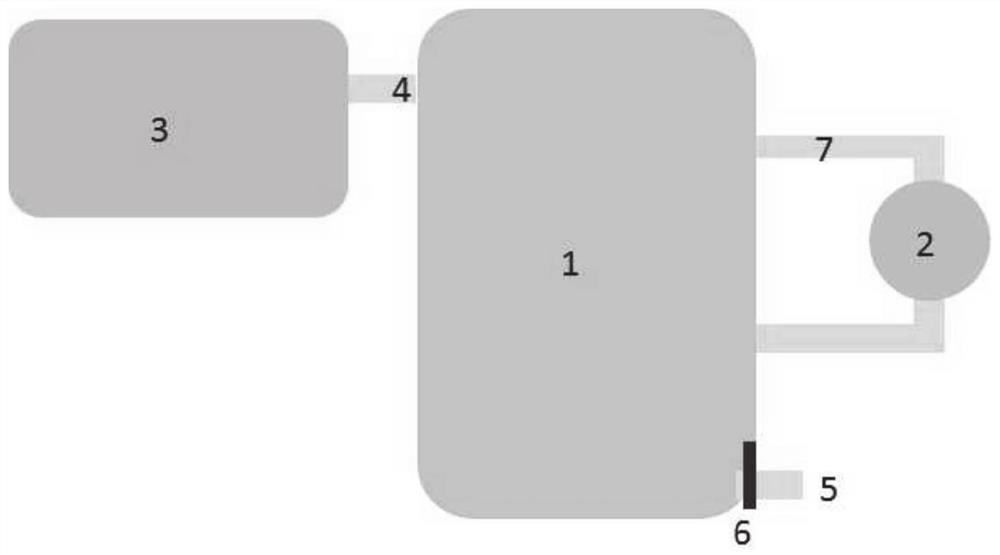

Method used

Image

Examples

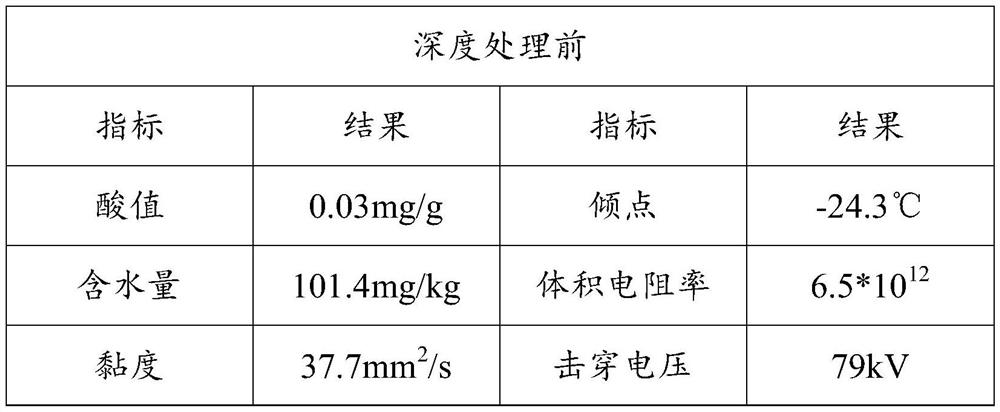

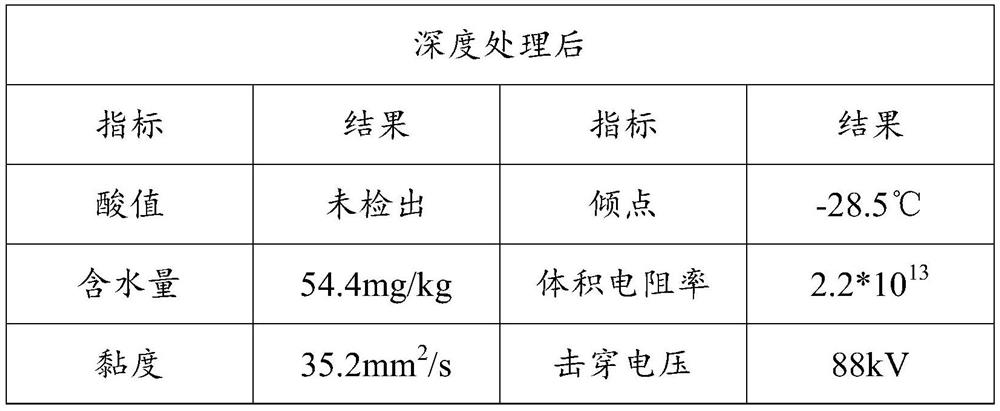

Embodiment 1

[0057] 1. Use 100-mesh and 200-mesh sieves to intercept the silica particles, soak the silica particles for 4 hours at 70°C with 5% hydrochloric acid, take them out after washing, and then wash them with sodium hydroxide, sodium carbonate, and sodium tartrate. , sodium cetyl sulfonate and disodium edetate with a total salt concentration of 5% (among them, sodium hydroxide, sodium carbonate, sodium tartrate, sodium cetyl sulfonate and ethylenediamine The mass ratio of disodium tetraacetate is 10:5:2:1:1) for heating and soaking, the heating temperature is 60°C, the soaking time is 2h, after washing, take out and dry, the drying temperature is 70°C, the drying time for 5 hours; put the soaked and dried silicon oxide into a muffle furnace for calcination, the heating rate is controlled at 5°C / min, the calcination temperature is 700°C, and the heat preservation is continued for 4h. After cooling, the superhydrophilic adsorbent is taken out and placed Store in a desiccator.

[005...

Embodiment 2

[0064] 1. The preparation and advanced treatment process steps of the superhydrophilic adsorbent are the same as in Example 1.

[0065] 2. Select a natural ester insulating oil derived from palm oil on the market as the treatment object.

[0066] 3. The processing and analysis process is the same as in Example 1, and the analysis data of the advanced processed palm insulating oil are shown in Table 2

[0067] Table 2

[0068]

Embodiment 3

[0070] 1. Adsorption process and drying process steps are the same as in Example 1.

[0071] 2. Select natural ester insulating oil from a rapeseed oil source on the market as the treatment object.

[0072] 3. The processing and analysis process is the same as in Example 1, and the analysis data of the rapeseed insulating oil after advanced treatment are shown in Table 3.

[0073] table 3

[0074]

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com