A biodiesel production system

A biodiesel and production system technology, applied in biofuels, fatty acid production, petroleum industry, etc., can solve problems such as increased waste water treatment costs, decreased product yield, low added value, etc., to avoid water pollution, prevent polymerization, The effect of avoiding air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

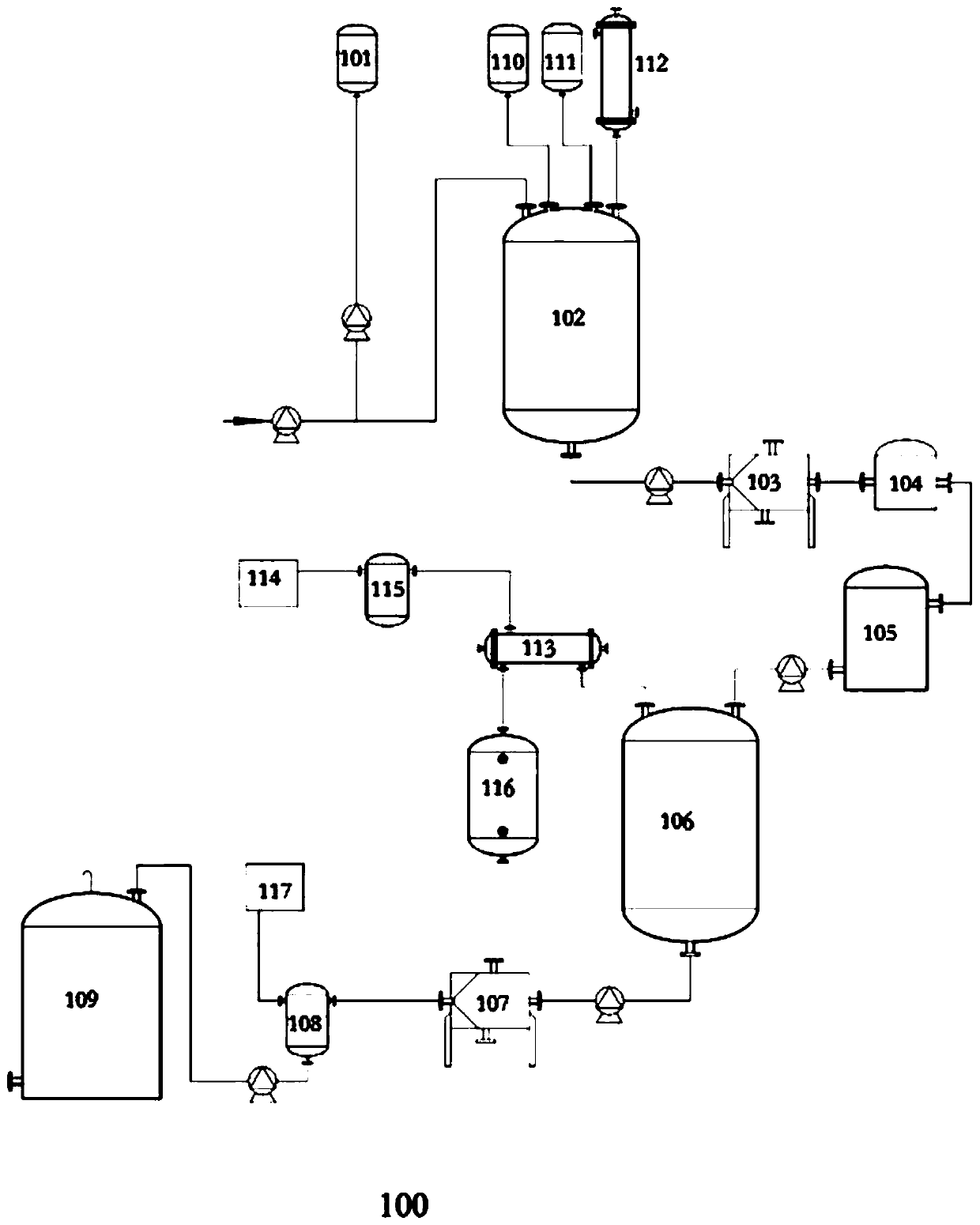

[0045] This embodiment provides a biodiesel production system, including a first production unit 100 and a refined biodiesel production unit;

[0046] Such as figure 1 As shown, the first production unit 100 includes a first esterification tank 102, a first heat exchanger 103, a first centrifuge 104, a first temporary storage tank 105, a methanol recovery tank 106, a second Heat exchanger 107, first drier 108 and second temporary storage tank 109, the first esterification tank 102 is communicated with the first methanol tank 101 and the first catalyst addition tank 110 through the pipeline, the first esterification tank 102 entrance A feed pipe is provided, and the methanol recovery tank 106 is also communicated with a first condenser 113, and the first condenser 113 is communicated with a first vacuum pump 114 and a first methanol collection tank 116; the top of the first esterification tank 102 is also communicated with a first Auxiliary material addition tank 111 and secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com