Method for quantitatively determining 3-hydroxybutanone in fermentation liquid

A technology for the quantitative determination of hydroxybutanone, which is applied in the field of analysis and detection, to achieve the effects of reducing workload, fast detection speed and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

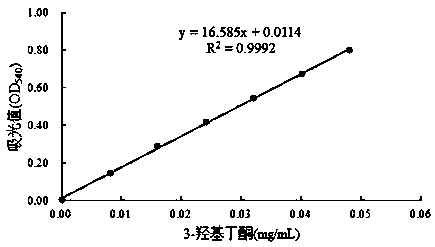

[0038] Draw 3-hydroxybutanone standard curve

[0039] ① Prepare 3-hydroxybutanone standard solution;

[0040] Accurately weigh 100 mg of 3-hydroxybutanone standard sample, 3-hydroxybutanone is pre-dried in an oven at 50°C to constant weight, placed in a small beaker, dissolved with a small amount of distilled water, quantitatively transferred to a 100mL volumetric flask, and Dilute to the mark with distilled water, shake well, and store in the refrigerator for later use.

[0041] ② Preparation of 3,5-dinitrosalicylic acid reagent;

[0042]Add 6.3g of 3,5-dinitrosalicylic acid and 262mL of 2mol / L NaOH solution to 500mL of hot water solution containing 185g of potassium sodium tartrate, add 5g of crystalline phenol and 5g of sodium sulfite, stir to dissolve; add distilled water after cooling Dilute to 1000mL to prepare 3,5-dinitrosalicylic acid reagent, store it in a brown bottle for later use;

[0043] ③Respectively take 0, 0.2, 0.4, 0.6, 0.8, 1.0, 1.2mL 3-hydroxybutanone st...

Embodiment 2

[0052] 3-Hydroxybutanone fermentation medium composition: glucose 50g / L, yeast extract 10.3 g / L, corn steep liquor 19.8g / L, manganese sulfate 0.193 g / L, ferrous sulfate 0.11 g / L, ammonium sulfate 7.0g / L, magnesium sulfate 0.2 g / L.

[0053] 3-Hydroxybutanone fermentation The fermentation conditions are: fermentation temperature 37°C, shaker rotation speed 180r / min, liquid seed inoculum amount 2-3%, adding 1% calcium carbonate to the medium to control the pH value.

[0054] When the shake flask was fermented for 72 hours, the glucose was exhausted, and the fermentation clear night was obtained by centrifugation.

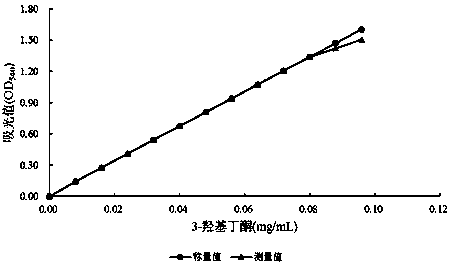

[0055] After diluting the above fermented clear liquid with distilled water 100 times, add 3,5-dinitrosalicylic acid reagent, heat and boil for 5 minutes, and measure the absorbance of the solution after the reaction is completed;

[0056] Substitute the detected absorbance value into a linear equation to obtain the concentration of 3-hydroxybutanone in the fermentati...

Embodiment 3

[0062] 3-Hydroxybutanone fermentation medium composition: glucose 100g / L, yeast extract 11.5 g / L, corn steep liquor 20.5g / L, manganese sulfate 0.193 g / L, ferrous sulfate 0.11 g / L, ammonium sulfate 9.0g / L, magnesium sulfate 0.3 g / L.

[0063] 3-Hydroxybutanone fermentation The fermentation conditions are as follows: fermentation temperature 37°C, shaker rotation speed 180r / min, liquid seed inoculation amount 2-3%, adding 1.5% calcium carbonate to the medium to control the pH value.

[0064] When the shake flask was fermented for 80 hours, the glucose was exhausted, and the fermentation clear night was obtained by centrifugation.

[0065] After diluting the above fermented clear liquid with distilled water 100 times, add 3,5-dinitrosalicylic acid reagent, heat and boil for 5 minutes, and measure the absorbance of the solution after the reaction is completed;

[0066] Substitute the detected absorbance value into a linear equation to obtain the concentration of 3-hydroxybutanone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com