A natural corn cotton cup

A technology of corn and cotton cups, applied in the field of bras and underwear, can solve problems such as mastitis, environmental pollution, and health damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

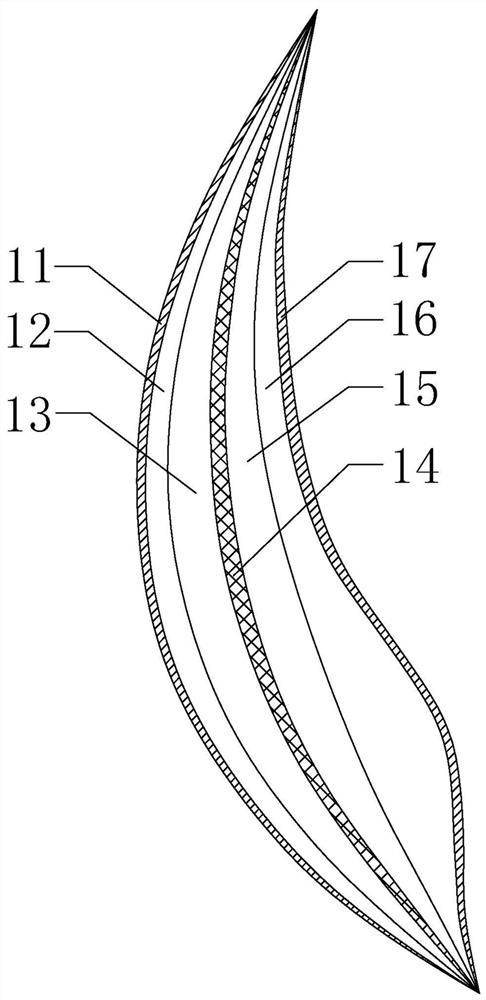

[0051] See figure 1 , a natural corn cotton cup, comprising two symmetrically arranged cups 1, characterized in that: said cup 1 comprises a first cotton cloth layer 11, a first corn cotton layer 12, a second corn cotton layer connected sequentially from outside to inside Layer 13, rubber mesh layer 14, the third corn cotton layer 15, the fourth corn cotton layer 16 and the second cotton cloth layer 17; the first corn cotton layer 12, the second corn cotton layer 13, the third corn cotton layer 15 And the 4th corn cotton layer 16 all is made by weaving of corn fiber.

[0052] The thickness of the first corn cotton layer 12 is 3.5-4.5mm, the thickness of the second corn cotton layer 13 is 7-9mm, the thickness of the third corn cotton layer 15 is 9-11mm, and the fourth The thickness of the corn cotton layer 16 is 5-7mm, the thickness of the first cotton layer 11 and the second cotton layer 17 is 0.8-1.2mm, the thickness of the glue net layer 14 is 1.2-1.8mm, the glue The mesh ...

Embodiment 2

[0054] The difference between this embodiment and above-mentioned embodiment 1 is:

[0055] The corn fiber is made from polylactic acid masterbatch, and the polylactic acid masterbatch includes the following raw materials in parts by weight:

[0056] 30 parts polylactic acid

[0057] Inorganic filler 10 parts

[0058] Antistatic agent 0.2 parts

[0059] Antioxidant 0.6 parts

[0060] 0.5 parts of coupling agent

[0061] 0.3 part of polymerization inhibitor.

[0062] The inorganic filler includes 1 part of kaolin, 1 part of cordierite powder, 3 parts of mica powder, 0.5 part of silicon dioxide, 1.0 part of calcium carbonate and 0.8 part of aluminum oxide.

[0063] The antistatic agent is a mixture of polyoxyethylene alkyl ether, alkyl dicarboxymethyl betaine and monoglyceride stearate in a weight ratio of 1:1:2.5; the antioxidant is composed of A mixture of dioctadecyl pentaerythritol diphosphite and 2,6-di-tert-butyl-p-cresol in parts by weight of 1:2.

[0064] The coupli...

Embodiment 3

[0080] The difference between this embodiment and above-mentioned embodiment 1 is:

[0081] The corn fiber is made from polylactic acid masterbatch, and the polylactic acid masterbatch includes the following raw materials in parts by weight:

[0082] Polylactic acid 32 parts

[0083] Inorganic filler 10.5 parts

[0084] Antistatic agent 0.4 parts

[0085] Antioxidant 0.7 parts

[0086] 0.8 parts of coupling agent

[0087] 0.4 part of polymerization inhibitor.

[0088] The inorganic filler includes 1.2 parts of kaolin, 1.5 parts of cordierite powder, 3.2 parts of mica powder, 0.8 part of silicon dioxide, 1.1 part of calcium carbonate and 0.9 part of aluminum oxide.

[0089] Described antistatic agent is the mixture that is 1.2:1:2.8 to form by weight ratio of polyoxyethylene alkyl ether, alkyl dicarboxymethyl betaine and monoglyceride stearate; Described antioxidant is composed of A mixture of dioctadecyl pentaerythritol diphosphite and 2,6-di-tert-butyl-p-cresol in parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com