A method for preparing a palladium catalyst supported by chitosan-carboxymethyl cellulose composite nanoparticles

A technology of nano-microspheres and palladium catalysts, which is applied in the field of catalysis, can solve the problems of selectivity decline, etc., and achieve the effects of short reaction time, mild reaction conditions and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

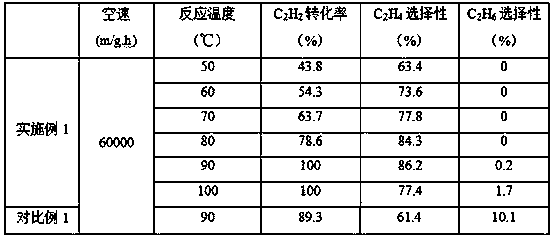

Examples

Embodiment 1

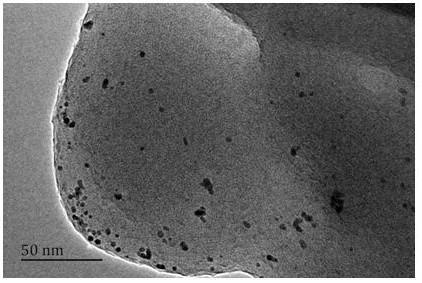

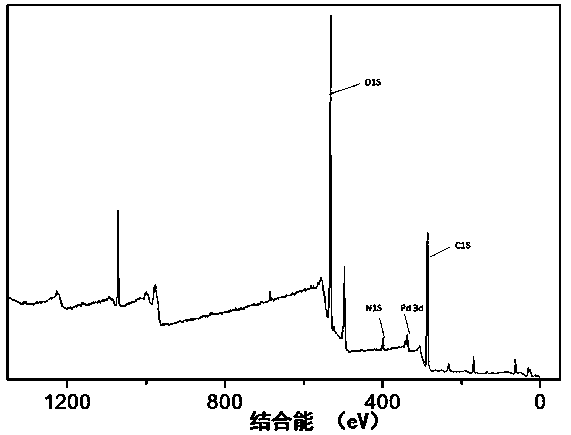

[0022] A kind of preparation method of chitosan and cellulose composite nano microsphere supported palladium catalyst, concrete steps are as follows:

[0023] (1) According to the ratio of mass volume ratio g:mL of 1:100, mix chitosan and absolute ethanol, stir magnetically for 20 minutes, and the stirring speed is 500r / min to obtain solution A; according to the mass volume ratio g:mL is The ratio of 1:100 is mixed with carboxymethyl cellulose and alkaline solution, the alkaline solution is a KOH solution with a pH value of 11, magnetically stirred for 2 hours, and the stirring speed is 500r / min to obtain solution B;

[0024] (2) According to the volume ratio of 1:1, add the solution A of step (1) into the solution B dropwise at a rate of 0.1mL / s, stir and react at room temperature for 4h, and the magnetic stirrer rotates at 500r / min. After filtering, washing with absolute ethanol for 3 times, the composite nano-microspheres of chitosan and carboxymethyl cellulose are obtained...

Embodiment 2

[0028] A kind of preparation method of chitosan and cellulose composite nano microsphere supported palladium catalyst, concrete steps are as follows:

[0029] (1) According to the ratio of mass volume ratio g:mL of 2:100, mix chitosan and absolute ethanol, stir magnetically for 25 minutes, and the stirring speed is 480r / min to obtain solution A; according to the mass volume ratio g:mL The ratio of 2:100 is mixed with carboxymethyl cellulose and alkaline solution, the alkaline solution is NaOH solution with a pH value of 12, magnetically stirred for 1.5h, and the stirring speed is 480r / min to obtain solution B;

[0030] (2) According to the volume ratio of 1:1.5, add solution A of step (1) dropwise to solution B at a rate of 0.2mL / s, stir and react at room temperature for 3h, and the magnetic stirrer rotates at 480r / min, Washing with absolute ethanol twice after filtering to obtain chitosan and carboxymethyl cellulose composite nano-microspheres;

[0031] (3) Add the nano-micr...

Embodiment 3

[0033] A kind of preparation method of chitosan and cellulose composite nano microsphere supported palladium catalyst, concrete steps are as follows:

[0034] (1) According to the ratio of mass volume ratio g:mL of 3:100, mix chitosan and absolute ethanol, stir magnetically for 30 minutes, and the stirring speed is 450r / min to obtain solution A; according to the mass volume ratio g:mL The ratio of 3:100 is mixed with carboxymethyl cellulose and alkaline solution, the alkaline solution is ammonia water with a pH value of 11, magnetically stirred for 1 hour, and the stirring speed is 450r / min to obtain solution B;

[0035] (2) According to the volume ratio of 1:2, add the solution A of step (1) into the solution B dropwise at a rate of 0.5mL / s, stir and react at room temperature for 4h, and the magnetic stirrer rotates at 450r / min. After filtering, washing with absolute ethanol for 3 times, the composite nano-microspheres of chitosan and carboxymethyl cellulose are obtained;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com