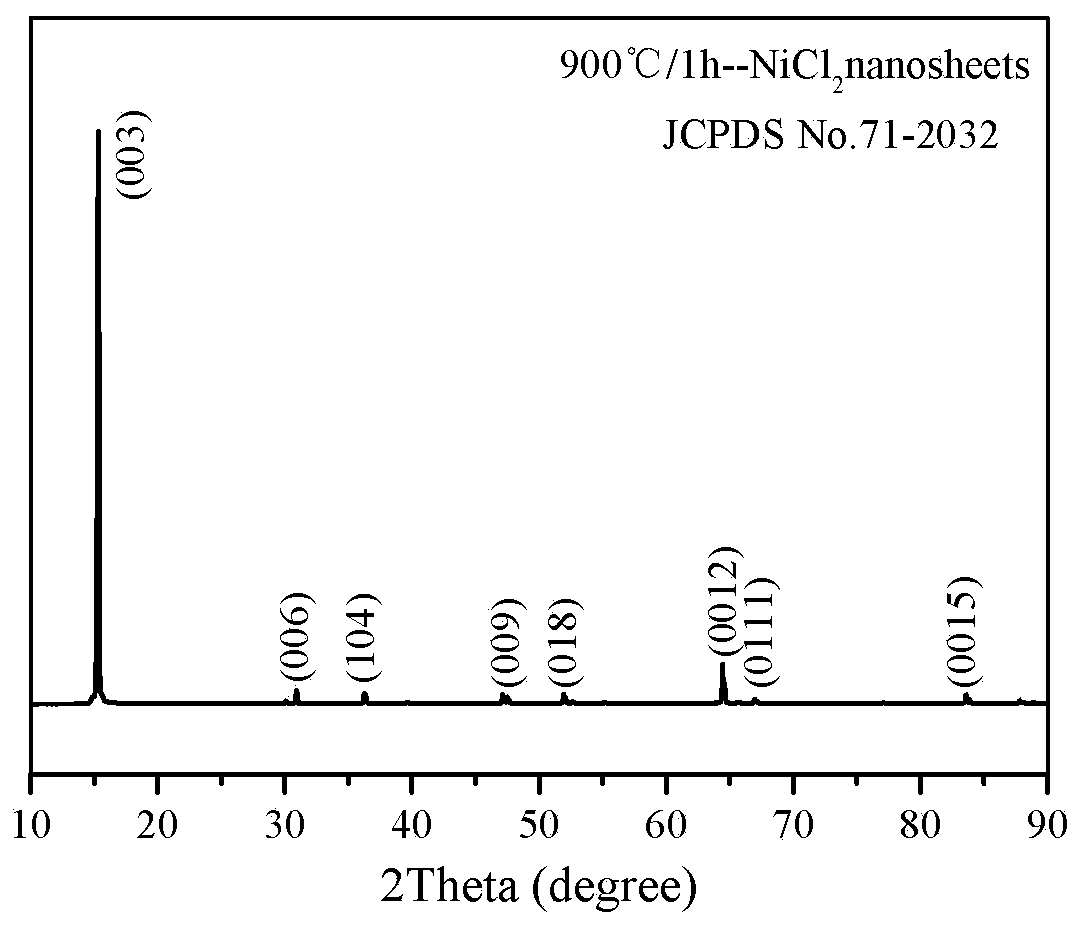

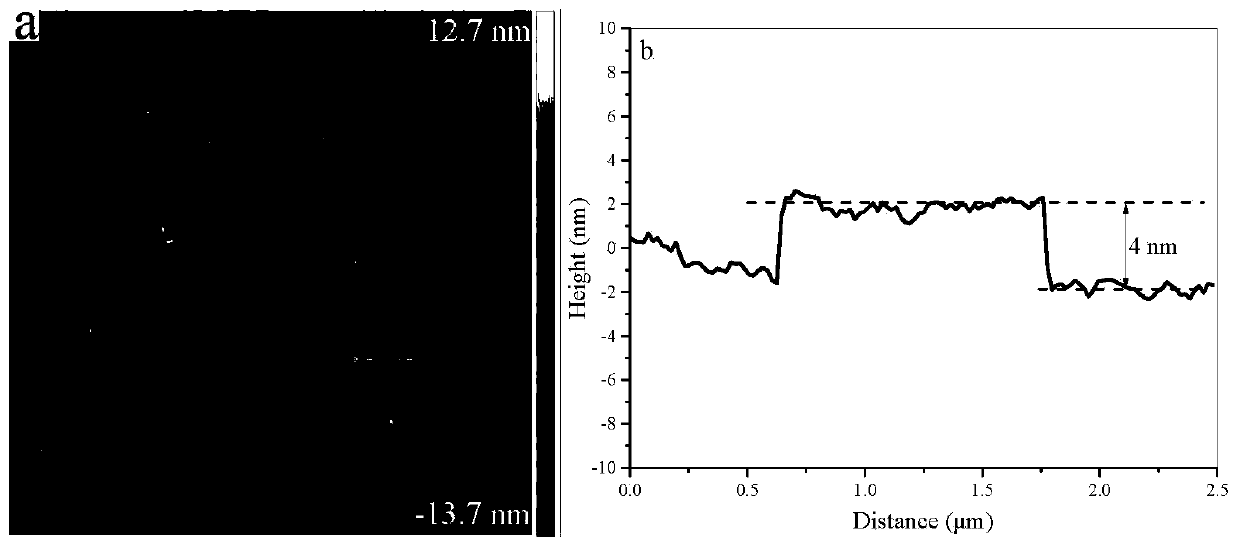

An ultrathin single crystal nicl 2 Nanosheet and its preparation method and application

A nanosheet and single crystal technology, which is applied in the field of ultra-thin single crystal material preparation, can solve the problems that nanosheets have not been reported yet, and achieve the effects of suitable batch preparation, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1 Nickel chloride hexahydrate crystal (NiCl 2 ·6H 2 O) Put it in an alumina crucible, put it into a tube furnace, and under the protection of an inert gas, raise the temperature to 270°C at a heating rate of 5°C / min, keep it warm for 2h, cool down to room temperature naturally, and take out the sintered sample; replace Clean quartz tube A,

[0046] 2. Spread the fine powder in an open ceramic crucible, and place it in the center of the clean and dry quartz tube A (the position of the effective high temperature zone of the tube furnace);

[0047] 3. Embed the quartz tube collector embedded with two perforated quartz plates (aperture 2-10 mm) in the low temperature area of the tube furnace quartz tube near the gas outlet; the flow direction of the perforated quartz plate and the protective gas is 90°.

[0048] 4. Vacuum, and then pass in Ar or N 2 Wait for protective gas; keep the gas flow at 50 sccm during the period from room temperature to 600 °C and during coolin...

Embodiment 2

[0053] 1 Nickel chloride hexahydrate crystal (NiCl 2 ·6H 2 O) Put it in an alumina crucible, put it into a tube furnace, and under the protection of an inert gas, raise the temperature to 250°C at a heating rate of 5°C / min, keep it warm for 3h, cool down to room temperature naturally, and take out the sintered sample; replace Clean quartz tube A;

[0054] 2. Spread the fine powder in an open ceramic crucible, and place it in the center of the clean and dry quartz tube A (the position of the effective high temperature zone of the tube furnace);

[0055] 3. Embed the quartz tube collector embedded with two perforated quartz plates (aperture 2-10 mm) in the low temperature area of the tube furnace quartz tube near the gas outlet; the flow direction of the perforated quartz plate and the protective gas is 90°.

[0056] 4. Vacuum, and then pass in Ar or N 2 Wait for protective gas; keep the gas flow at 50 sccm during the period from room temperature to 600 °C and during coolin...

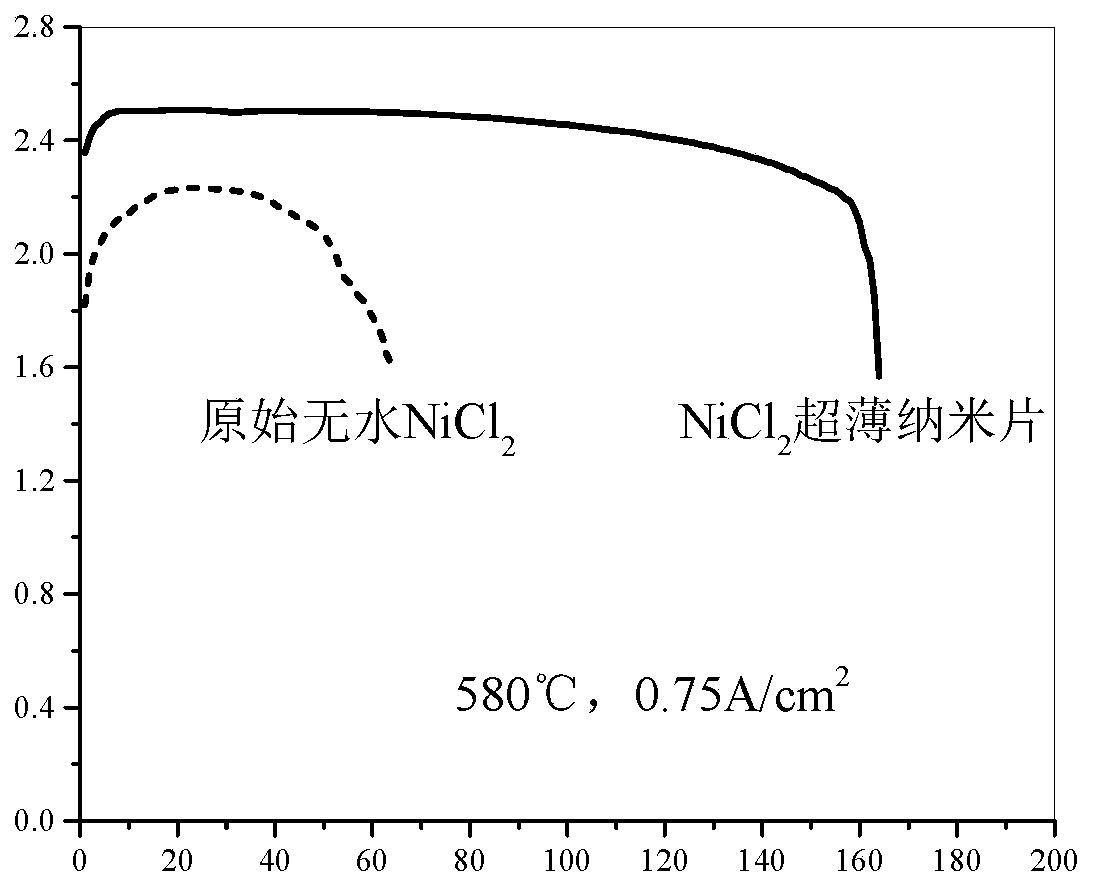

Embodiment 3

[0062] Nickel chloride hexahydrate crystals (NiCl 2 ·6H 2 O) Put it in an alumina crucible, put it into a tube furnace, and under the protection of an inert gas, raise the temperature to 250°C at a heating rate of 5°C / min, keep it warm for 3h, cool down to room temperature naturally, take out the sintered sample, and grind save.

[0063] The resulting product powder shows through FE-SEM analysis that the prepared anhydrous NiCl 2 , showing a rod shape, the end face is a square with a size of submicron, and the length is more than 3 microns; the obtained anhydrous NiCl 2 The powder is matched with LiB negative electrode and ternary electrolyte (LiF-LiCl-LiBr) to prepare a monothermal battery system and at 0.75A cm -2 --Discharge at 580°C, the maximum working voltage is only 2.17V, and there is no discharge platform, the test results show that anhydrous NiCl 2 The specific power of the powder is ~24kW kg -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com