Inorganic-organic composite polymer phosphorus removal flocculating agent and preparation method thereof

A composite polymer and flocculant technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water pollutants, etc., can solve the problems of efficient removal of phosphorus in wastewater, achieve large molecular weight, reduce turbidity, The effect of fast settling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

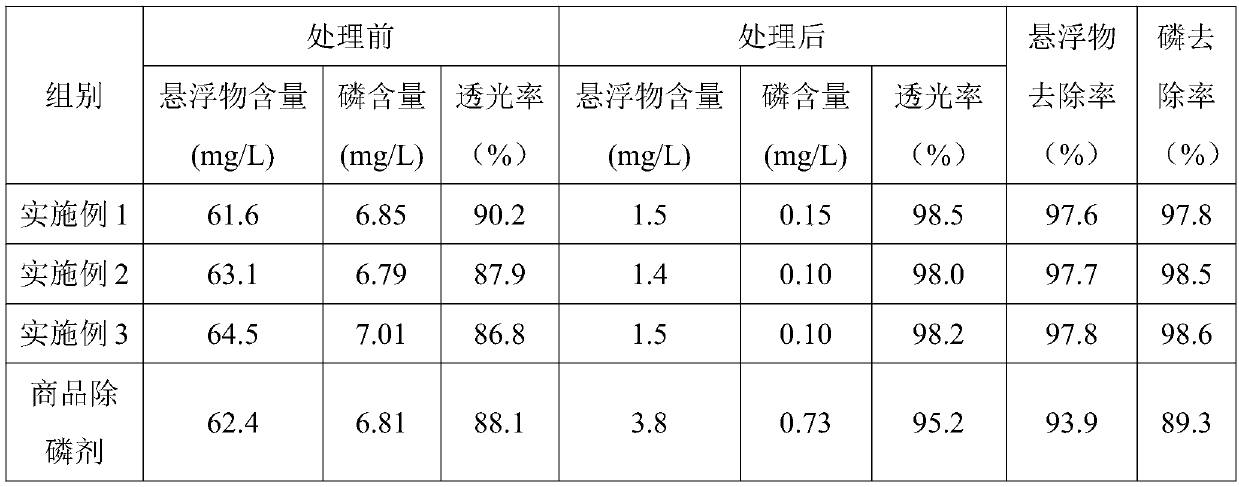

Embodiment 1

[0020] Take 10g of polyaluminum chloride with a balance, dissolve it in 200mL of distilled water, and make an aqueous solution with a mass concentration of 5%, then add 2g of silane coupling agent 3-(methacryloyloxy)propyltrimethoxysilane, in The reaction was stirred at room temperature for 4 hours. Then add 16g of acrylamide, 8g of 2-acrylamide-2-methylpropanesulfonic acid and 2g of urea, after the polymer monomer is fully stirred and dissolved, adjust the pH to 7.0 with 0.1mol / L hydrochloric acid, and pass nitrogen gas Deoxidize for 15 minutes, heat up to 55-60°C, add 2 mL of 10% initiator ammonium persulfate solution dropwise under stirring, and react at constant temperature for 4 hours to obtain the target product. The average molecular weight of the target product is measured to be 5.5 million. The target product is granulated and dried to obtain an inorganic-organic composite polymer phosphorus removal flocculant.

Embodiment 2

[0022] Take 10g of polyaluminum chloride with a balance, dissolve it in 200mL of distilled water, and make an aqueous solution with a mass concentration of 5%, then add 2.6g of silane coupling agent 3-(methacryloyloxy)propyltrimethoxysilane, The reaction was stirred at room temperature for 5 hours. Then add 25g of acrylamide, 8.4g of 2-acrylamide-2-methylpropanesulfonic acid and 2.1g of urea, after the polymer monomer is fully stirred and dissolved, adjust the pH to 7.0 with 0.1mol / L hydrochloric acid, and Nitrogen was used to remove oxygen for 15 minutes, the temperature was raised to 60-65°C, 4.8mL of 10% initiator ammonium persulfate solution was added dropwise under stirring, and the target product was obtained after constant temperature reaction for 4.5 hours. The average molecular weight of the target product was measured to be 7 million. The target product is granulated and dried to obtain an inorganic-organic composite polymer phosphorus removal flocculant.

Embodiment 3

[0024] Take 10g of polyaluminum chloride with a balance, dissolve it in 200mL of distilled water, and make an aqueous solution with a mass concentration of 5%, then add 3.2g of silane coupling agent 3-(methacryloyloxy)propyltrimethoxysilane, The reaction was stirred at room temperature for 6 hours. Then add 32.5g of acrylamide, 8.8g of 2-acrylamide-2-methylpropanesulfonic acid and 2.2g of urea, and adjust the pH to 7.0 with 0.1mol / L hydrochloric acid after the polymer monomer is fully stirred and dissolved. And pass nitrogen gas to remove oxygen for 15 minutes, heat up to 60-65 °C, add 5.6 mL of 10% initiator ammonium persulfate solution dropwise under stirring, and react at constant temperature for 4.5 hours to obtain the target product, and the average molecular weight of the target product is measured to be 9.5 million . The target product is granulated and dried to obtain an inorganic-organic composite polymer phosphorus removal flocculant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com