Preparation methods of radix curcumae wenyujin agglutinin crude product, radix curcumae wenyujin agglutinin pure product and PGRP bacterial strain mixture, and radix curcumae wenyujin fertilizer

A strain mixture and the technology of warming turmeric, applied to the preparation method of peptides, organic fertilizers, chemical instruments and methods, etc., can solve the problems of less lectin and unfavorable production utilization, etc., and achieve simple preparation process, convenient industrial production, and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

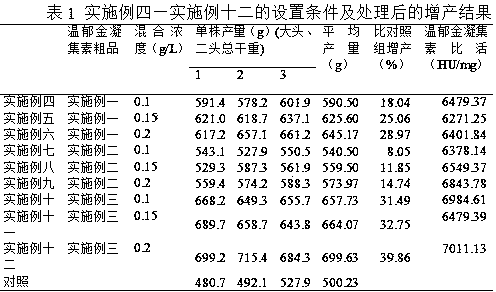

Examples

Embodiment 1

[0022] (1) Take 1 kg of fresh turmeric, slice it, crush it and beat it to get the slurry raw material, centrifuge it at 4°C and 9500r / min for 35min, discard the supernatant, and get the first sediment;

[0023] (2) Add 1~3% compound enzyme solution to the phosphate buffer solution with pH of 5.5~6.5, the compound enzyme solution is cellulase: pectinase=2.5:1, and the first sediment Mix at a volume ratio of 6:1, stir at room temperature for 5 hours at low speed after mixing, then centrifuge at 4°C and 2000 r / min for 10 minutes, take the supernatant, and then centrifuge at 4°C and 9500 r / min for 35 minutes. Discard the supernatant to obtain the second precipitate;

[0024] (3) Add pre-cooled petroleum ether to the second sediment at a volume ratio of 1:1, stir at a low speed for 25 minutes at 4°C, filter with suction, add pre-cooled acetone at a volume ratio of 1:0.7, and let stand for 1 -2min, suction filtration, and air-dried to obtain the third precipitate;

[0025] (4) Add...

Embodiment 2

[0029] (1) Take 1 kg of fresh turmeric, slice it, crush it and beat it to get a pulpy raw material, centrifuge it at 4°C and 8000r / min for 40min, discard the supernatant, and get the first sediment;

[0030] (2) Add 1~3% compound enzyme solution to the phosphate buffer solution with pH of 5.5~6.5, the compound enzyme solution is cellulase: pectinase=2:1, and the first sediment Mix at a volume ratio of 5:1. After mixing, stir at a low speed for 5.5 hours at room temperature, then centrifuge at 4°C and 2000 r / min for 10 minutes, take the supernatant, and then centrifuge at 4°C and 8000 r / min for 40 minutes. Discard the supernatant to obtain the second precipitate;

[0031] (3) Add pre-cooled petroleum ether to the second sediment at a volume ratio of 1:2, stir at a low speed for 20 minutes at 4°C, filter with suction, add pre-cooled acetone at a volume ratio of 1:0.7, and let stand for 1 -2min, suction filtration, and air-dried to obtain the third precipitate;

[0032] (4) Add...

Embodiment 3

[0036] (1) Take 10kg of fresh curcuma, slice, crush and beat to obtain slurry raw material, centrifuge at 4°C and 10000r / min for 45min, discard the supernatant, and obtain the first sediment;

[0037] (2) Add 1~3% compound enzyme solution to the phosphate buffer solution with pH of 5.5~6.5, the compound enzyme solution is cellulase: pectinase=3:1, and the first sediment Mix at a volume ratio of 7:1, stir at room temperature for 5.5 hours at low speed after mixing, then centrifuge at 4°C and 2000 r / min for 10 minutes, take the supernatant, and then centrifuge at 4°C and 10000 r / min for 45 minutes. Discard the supernatant to obtain the second precipitate;

[0038] (3) Add pre-cooled petroleum ether to the second sediment at a volume ratio of 1:2, stir at a low speed for 20 minutes at 4°C, filter with suction, add pre-cooled acetone at a volume ratio of 1:0.7, and let stand for 1 -2min, suction filtration, and air-dried to obtain the third precipitate;

[0039] (4) Add phosphat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com