A kind of polymer and its preparation method and application

A technology of high polymer and molecular structure, applied in the field of polymer materials, can solve the problems of air pollution, environmental damage, inability to recycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

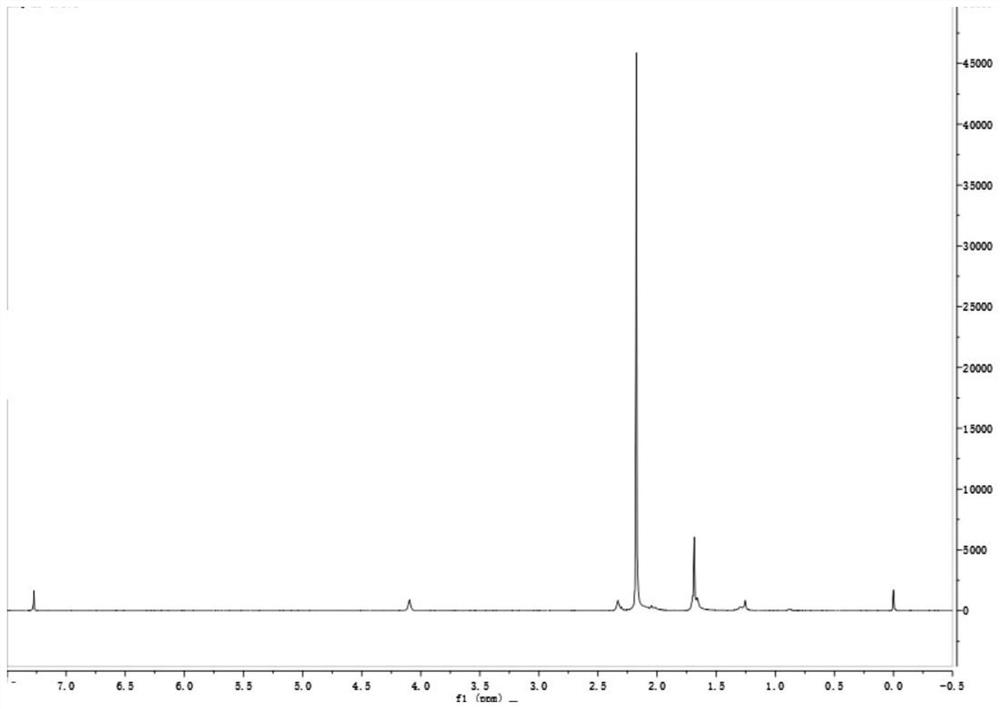

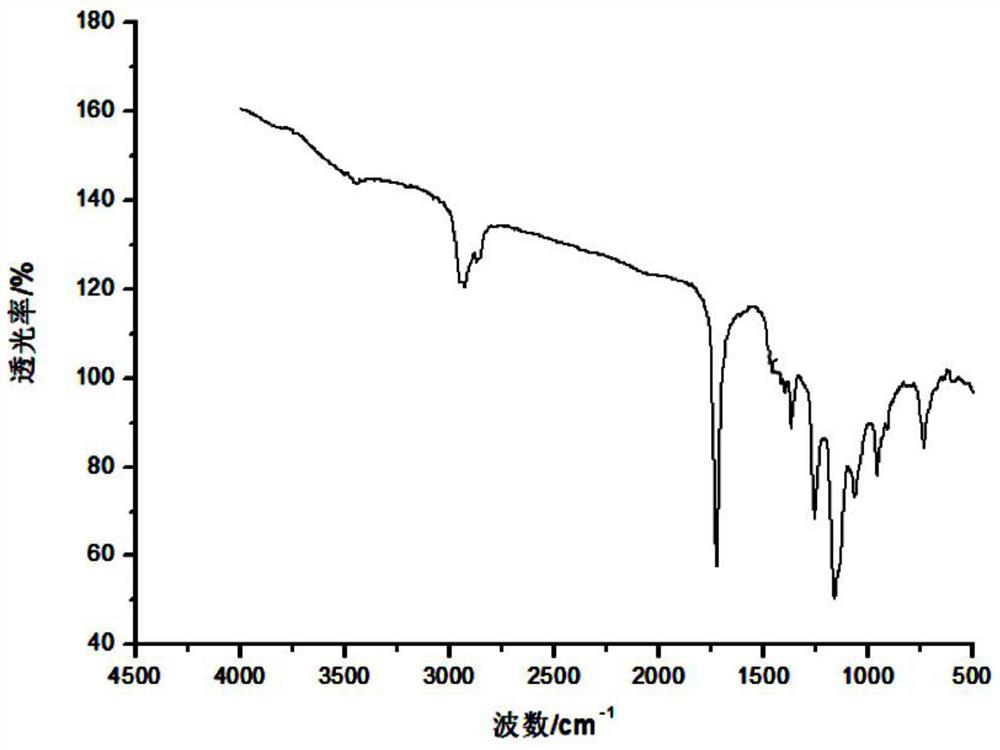

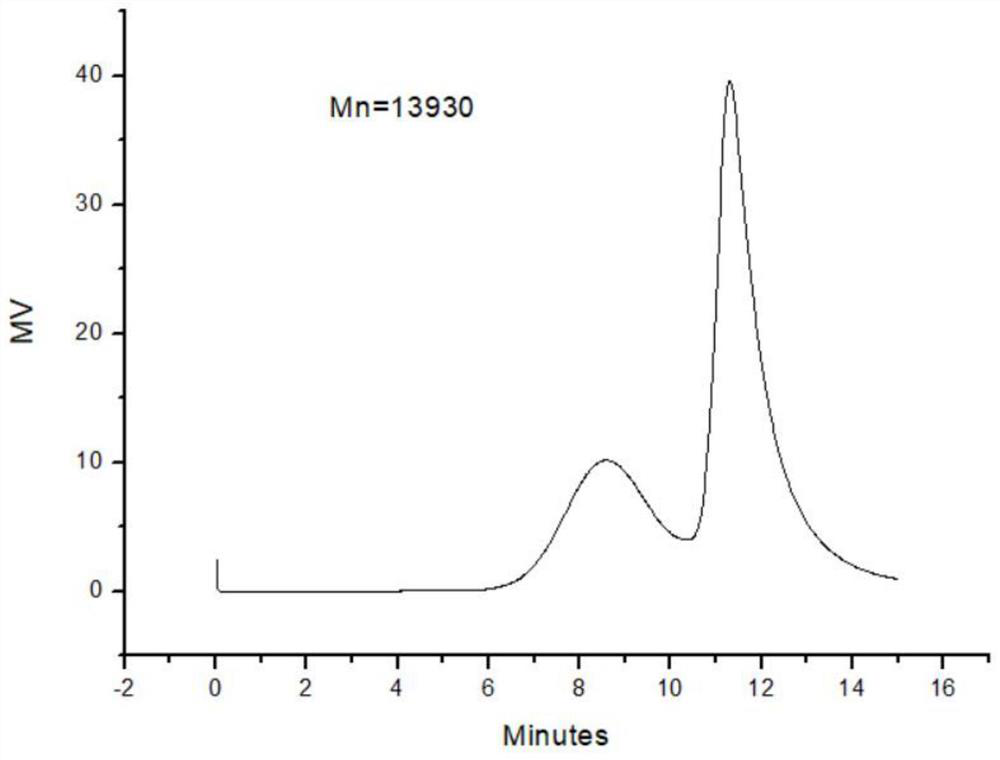

[0034] A kind of preparation method of polymer, comprises the following steps:

[0035] Step 1: Put 2.9g of castor oil, 20g of polybutylene adipate and 20ml of toluene into the reaction vessel A and mix them sequentially, and stir for 15min at 160°C and 500rad / min to obtain the mixed solution A;

[0036] Step 2: Put the mixed solution A prepared in step 1, 0.1g p-toluenesulfonic acid and 50ml tetrahydrofuran into the reaction vessel B, stir and mix, and stir for 20min at 80°C with a rotation speed of 300rad / min to obtain the mixed solution B ;

[0037] Step 3: At a temperature of 0°C and a stirring speed of 900 rad / min, add 1.6 g of diethylene glycol divinyl ether dropwise to the mixed solution B at a rate of 3 drops per 5 seconds; the addition ends Finally, raise the reaction temperature to 20°C, set the stirring speed to 1000 rad / min, and react for 5 hours; after the reaction is complete, rotate the mixed solution B to remove the solvent; then cool and solidify to obtain a ...

Embodiment 2

[0039] A kind of preparation method of polymer, comprises the following steps:

[0040] Step 1: Put 2g of castor oil, 23g of polybutylene adipate and 20ml of toluene into the reaction vessel A, stir and mix them sequentially, and stir for 15 minutes at 160° C. at a speed of 500 rad / min to obtain a mixed solution A;

[0041] Step 2: Put the mixed solution A prepared in step 1, 0.1g p-toluenesulfonic acid and 50ml tetrahydrofuran into the reaction vessel B, stir and mix, and stir for 20min at 80°C with a rotation speed of 300rad / min to obtain the mixed solution B ;

[0042] Step 3: At a temperature of 0°C and a stirring speed of 900 rad / min, add 1.5 g of diethylene glycol divinyl ether dropwise to the mixed solution B at a rate of 3 drops per 5 seconds; the addition ends Finally, raise the reaction temperature to 15°C, set the stirring speed to 1000 rad / min, and react for 6 hours; after the reaction is complete, rotate the mixed solution B to remove the solvent; then cool and s...

Embodiment 3

[0044] A kind of preparation method of polymer, comprises the following steps:

[0045] Step 1: Put 4g of castor oil, 18g of polybutylene adipate and 20ml of toluene into the reaction vessel A, stir and mix them in sequence, and stir for 15min at 160°C at a speed of 500rad / min to obtain a mixed solution A;

[0046] Step 2: Put the mixed solution A prepared in step 1, 0.1g p-toluenesulfonic acid and 50ml tetrahydrofuran into the reaction vessel B, stir and mix, and stir for 20min at 80°C with a rotation speed of 300rad / min to obtain the mixed solution B ;

[0047] Step 3: At a temperature of 0°C and a stirring speed of 900 rad / min, add 2 g of diethylene glycol divinyl ether dropwise to the mixed solution B at a rate of 3 drops per 5 seconds; , the reaction temperature was raised to 25°C, the stirring speed was set to 1000 rad / min, and the reaction was carried out for 4 hours; after the reaction was complete, the mixed solution B was rotary evaporated to remove the solvent; then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com