Method for measuring content of each component in ferro-titanium by X-ray fluorescence spectrometry

A fluorescence spectrometry and titanium-iron alloy technology is applied in the field of X-ray fluorescence spectroscopy to determine the content of each component in titanium-iron alloy, which can solve the problems of large consumption of chemical reagents, cumbersome detection process and high detection cost, and achieve stable and reliable results. The effect of shortening analysis time and wide detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Making the tablet to be tested: the ferro-titanium alloy is dried, crushed, mixed, fractionated, ground, and sieved to obtain a powder sample, sample 1.5g, and make a sample on the tablet machine as the sample to be tested; The pressure in the process of making samples on the tablet press is 20t and the time is 20s. The samples described use boric acid as the substrate. The mesh number of the sieving is 150. The specifications of the sample are: diameter 25mm, thickness 5mm.

[0036] 2. Under selected working conditions, use X-ray fluorescence spectrometer to measure standard samples. According to the known content and measurement intensity of standard samples, draw calibration curves and perform matrix correction, spectral line overlap interference correction, and component content of standard samples. The following table:

[0037] Titanium iron standard sample

[0038]

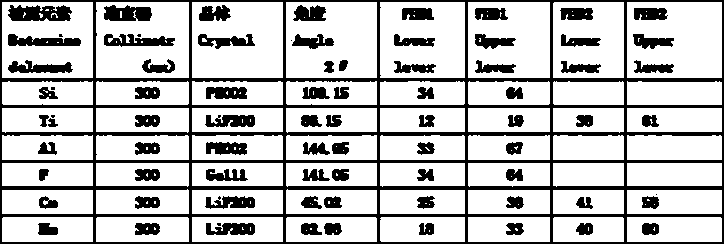

[0039] 3. Spectrometer parameter setting: select the Ka spectral line of each element as the analy...

Embodiment 2

[0048] 1. Making the tablet to be tested: the ferro-titanium alloy is dried, crushed, mixed, shrunk, ground, and sieved to obtain a powder sample, sample 1.8g, and make a sample on the tablet machine as the sample to be tested; The pressure in the process of making samples on the tablet press is 25 and the time is 30 seconds. The samples described use boric acid as the substrate. The mesh number of the sieving is 160. The specifications of the sample are: diameter 30mm, thickness 5.5mm.

[0049] 2. Spectrometer parameter setting: Calibrate the spectrometer, select the Ka spectral line of each element as the analysis line, and select the 2θ angle corresponding to the spectral line at the same time. The tube voltage is 45kV when measuring Ti, Mn, and Cu, and measuring Si, Al, P is 26 kV, the light tube current is 55mA when measuring Ti, Mn, Cu, and 120mA when measuring Si, Al, P;

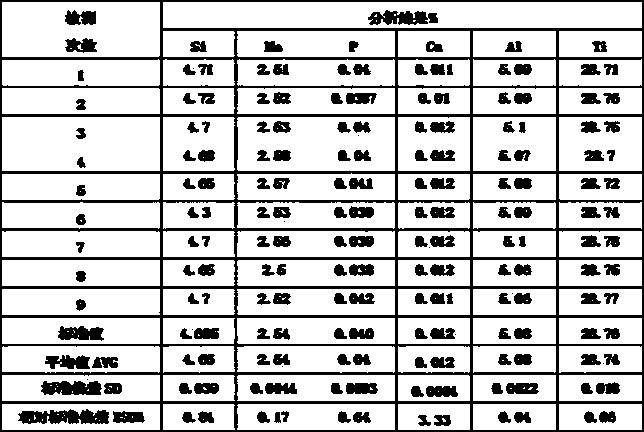

[0050] 3. According to the selected measurement conditions, use an X-ray fluorescence spectrometer t...

Embodiment 3

[0055] 1. Making the tablet to be tested: the ferro-titanium alloy is dried, crushed, mixed, shrunk, ground, and sieved to obtain a powder sample, sample 2g, and make a sample on the tablet machine as the sample to be tested; The pressure in the process of making samples on the tablet machine is 28t and the time is 35s. The samples described use boric acid as the substrate. The mesh number of the sieving is 170. The specifications of the sample are: 35mm in diameter and 5.8mm in thickness.

[0056] 2. Spectrometer parameter setting: Calibrate the spectrometer, select the Ka spectral line of each element as the analysis line, and select the 2θ angle corresponding to the spectral line at the same time. The light tube voltage is 48kV when measuring Ti, Mn, and Cu. When measuring Si, Al, P is 28kV, the light tube current is 58 mA when measuring Ti, Mn, and Cu, and when measuring Si, Al, and P, it is 123 mA;

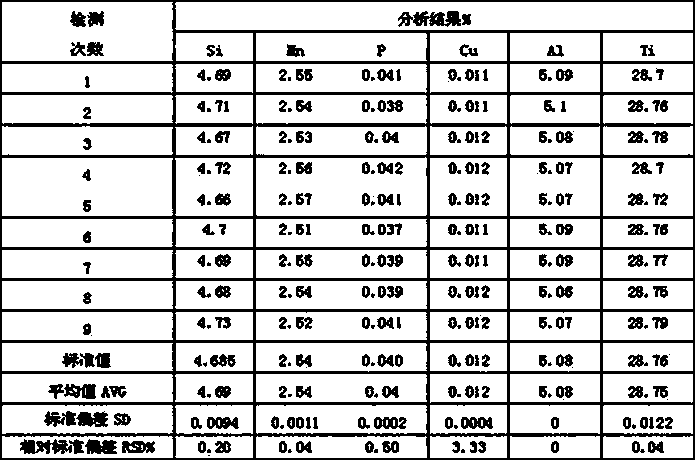

[0057] 3. According to the selected measurement conditions, use an X-ray f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com