Solvent-free template preparation method of porous carbon-coated nanometer metal particle

A technology of nano-metal particles and porous carbon, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of increasing the preparation cost of porous carbon-based materials, complex reaction process, and incompatible with green energy and other problems, to achieve the effect of improving limitations, high carbonization yield, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

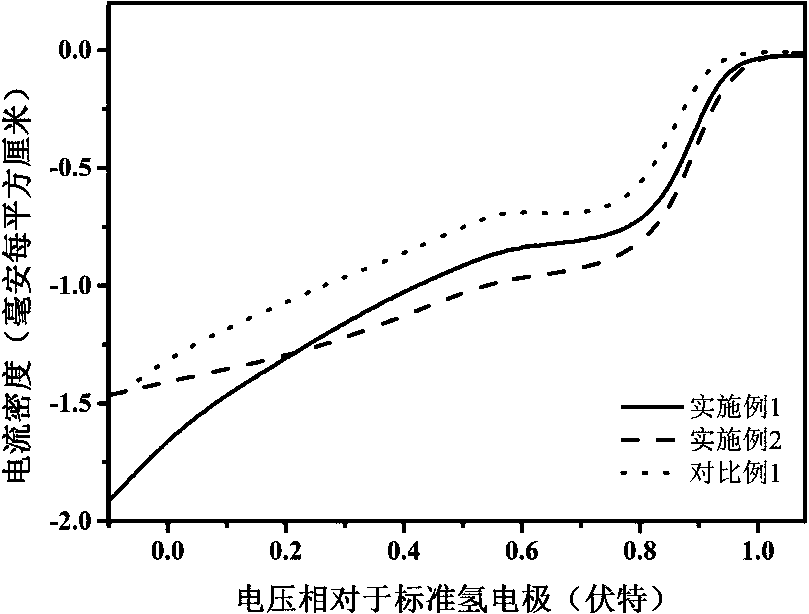

Embodiment 1

[0014] 1 g triblock polymer Pluronic F127, 0.22 g resorcinol, 0.4 g terephthalaldehyde, a certain amount of sodium sulfate (Na 2 SO 4 ) Grinding and mixing to form a viscous polymer, which is placed in a quartz boat at 100 degrees for 8 hours to heat and solidify, and then in a tube furnace in an inert atmosphere N 2 (100mL / min) at 600°C for 3 h (1°C / min heating rate). The obtained product is washed with water, dried and ground into powder in a mortar to obtain a porous carbon material.

Embodiment 2

[0016] 1 g triblock polymer Pluronic F127, 0.146 g cobalt nitrate (Co(NO 3 )·6H 2 O), 0.22 g resorcinol, and 0.4 g terephthalaldehyde were mixed, and the mixture was vigorously ground for 5 min to form a viscous polymer (adding a certain amount of sodium sulfate (Na 2 SO 4 )), ground and mixed, put it in a quartz boat at 100 degrees for 8 h to heat and solidify, and then in a tube furnace in an inert atmosphere N 2 (100 mL / min) at 600 °C for 3 h (1 °C / min heating rate). The powder was ground in a mortar, washed with water, and air-dried at 80°C for 6 hours to obtain porous carbon-coated cobalt nanoparticles (Co@C).

Embodiment 3

[0018] 1 g of triblock polymer Pluronic F127 was ground into powder in a mortar, 0.22 g of resorcinol was added, 0.4 g of terephthalaldehyde was added in three batches, and the mixture was vigorously ground for 5 min to form a viscous polymer (in A certain amount of sodium sulfate (Na 2 SO 4 ),, 0.3 g nickel chloride (NiCl 2 ·6H 2 O)), grind and mix, put it in a quartz boat at 100 degrees for 8 h to heat and solidify, then inert atmosphere N in a tube furnace 2 (100 mL / min) at 800 °C for 3 h (5 °C / min heating rate). The powder was ground in a mortar, washed with water, and air-dried at 80°C for 6 hours to obtain porous carbon-coated nickel nanoparticles (Ni@C).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com