Pimavanserin tablet and preparation method thereof

A technology of pimavanserin and tablets, which is applied in the field of pharmaceutical preparations and can solve the problems of poor stability of common preparations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

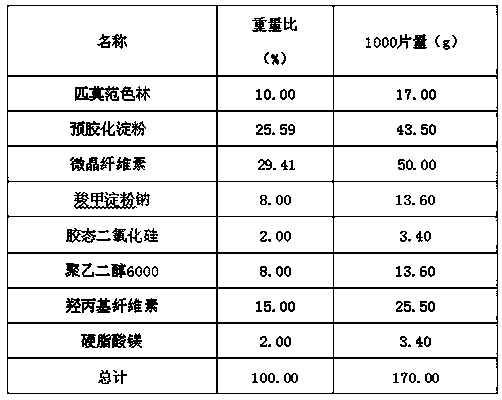

[0018] Prescription composition:

[0019]

[0020] Preparation Process:

[0021] Pass pimavanserin and all auxiliary materials through 80-mesh sieve respectively for later use; weigh the colloidal silicon dioxide, polyethylene glycol and the main drug in the prescribed amount and add them to the granulation pot, and stir at a stirring speed of 500r / min, Dry mix for 5 minutes at a shear speed of 1000r / min; then add pregelatinized starch, microcrystalline cellulose and sodium starch glycolate and mix well; slowly add 15% hydroxypropyl cellulose aqueous solution to make a soft material; granulate with a 24-mesh sieve , dried at 55°C for 1 hour, sieved with a 24-mesh sieve, weighed and mixed with the prescribed amount of magnesium stearate, and pressed into tablets.

Embodiment 2

[0023] Prescription composition:

[0024]

[0025] Preparation Process:

[0026] Pass pimavanserin and all auxiliary materials through 80-mesh sieve respectively for later use; weigh the colloidal silicon dioxide, polyethylene glycol and the main drug in the prescribed amount and add them to the granulation pot, and stir at a stirring speed of 500r / min, Dry mix for 5 minutes at a shear speed of 1000r / min; then add pregelatinized starch, microcrystalline cellulose and sodium starch glycolate and mix well; slowly add 10% hydroxypropyl cellulose aqueous solution to make a soft material; granulate with a 24-mesh sieve , dried at 55°C for 1 hour, sieved with a 24-mesh sieve, weighed and mixed with the prescribed amount of magnesium stearate, and pressed into tablets.

Embodiment 3

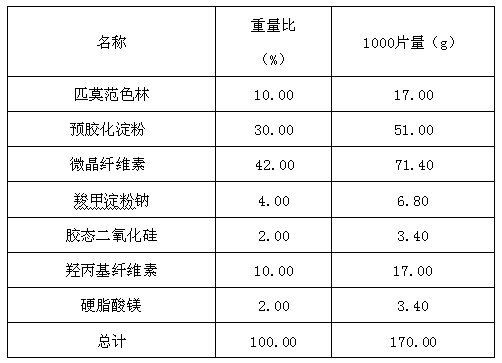

[0028] Prescription composition:

[0029]

[0030] Preparation Process:

[0031] Pass pimavanserin and all auxiliary materials through 80-mesh sieve respectively for later use; weigh the colloidal silicon dioxide, polyethylene glycol and the main drug in the prescribed amount and add them to the granulation pot, and stir at a stirring speed of 500r / min, Dry mix for 5 minutes at a shear speed of 1000r / min; then add pregelatinized starch, microcrystalline cellulose and sodium starch glycolate and mix well; slowly add 5% hydroxypropyl cellulose aqueous solution to make a soft material; granulate with a 24-mesh sieve , dried at 55°C for 1 hour, sieved with a 24-mesh sieve, weighed and mixed with the prescribed amount of magnesium stearate, and pressed into tablets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com