Preparation method of antibacterial and hemostatic microballoon containing berberine and application of antibacterial hemostatic microballoon

A technology of berberine and microspheres, applied in the application, pharmaceutical formulation, pharmaceutical science and other directions, can solve the problems of unsuitable hemostatic powder, difficult to degrade and absorb, and achieve the effects of shortening hemostasis time, convenient use and long storage time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Preparation of matrix solution: 15 g sodium alginate, 5 g carboxymethyl chitosan, 0.25 g collagen and 2 g berberine were added to 1000 ml water and dissolved respectively to make 4 parts of matrix solution.

[0040] 2. Material mixing: Mix 2500 ml liquid paraffin dispersant with 180 ml Tween 80 emulsifier, add sodium alginate, carboxymethyl chitosan and collagen mixed matrix solution to emulsify and stir for 1 hour, then add 2% w / w chlorine Calcium chloride 100 ml was added dropwise to the mixed material as a cross-linking agent with rapid stirring to carry out cross-linking reaction to prepare microspheres.

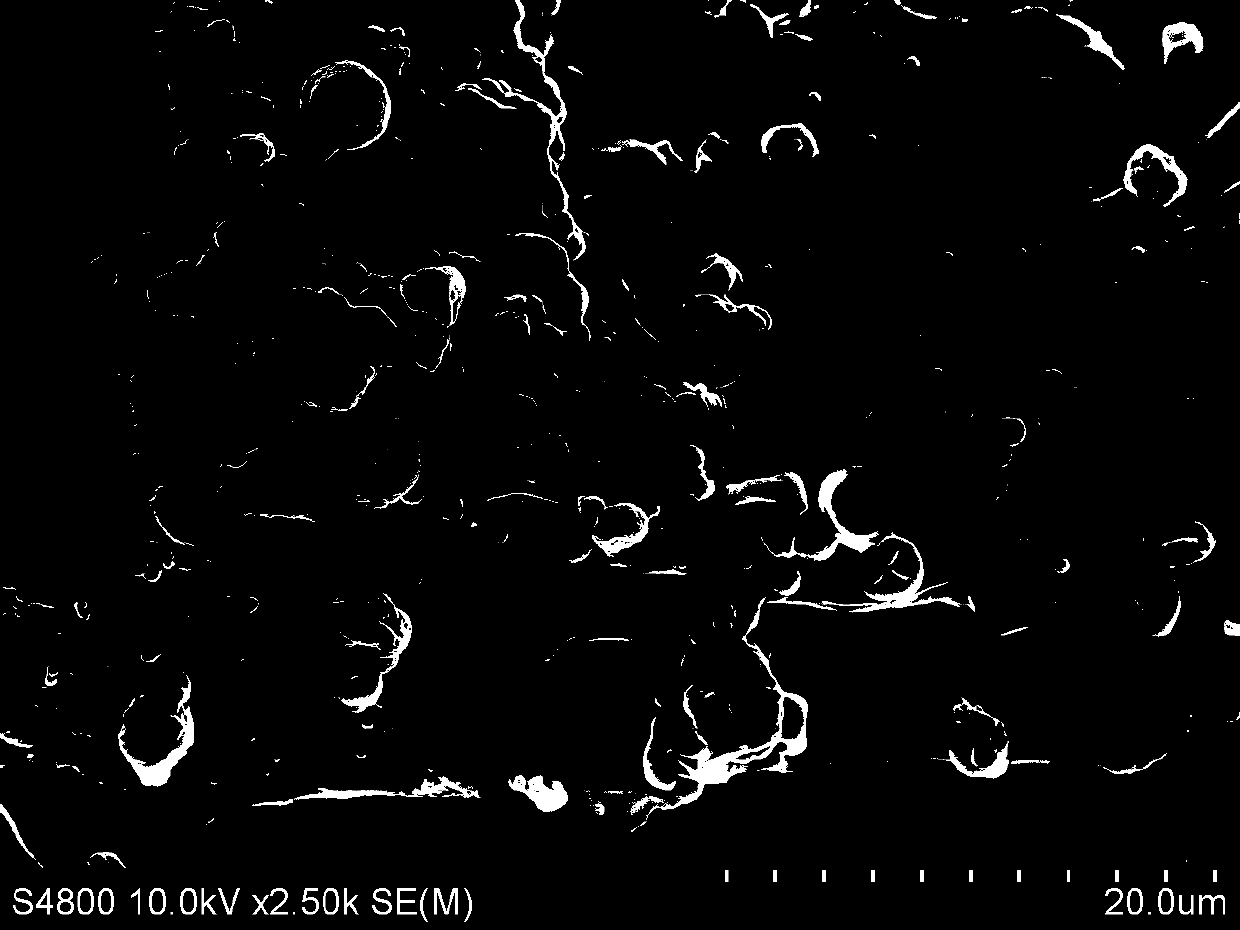

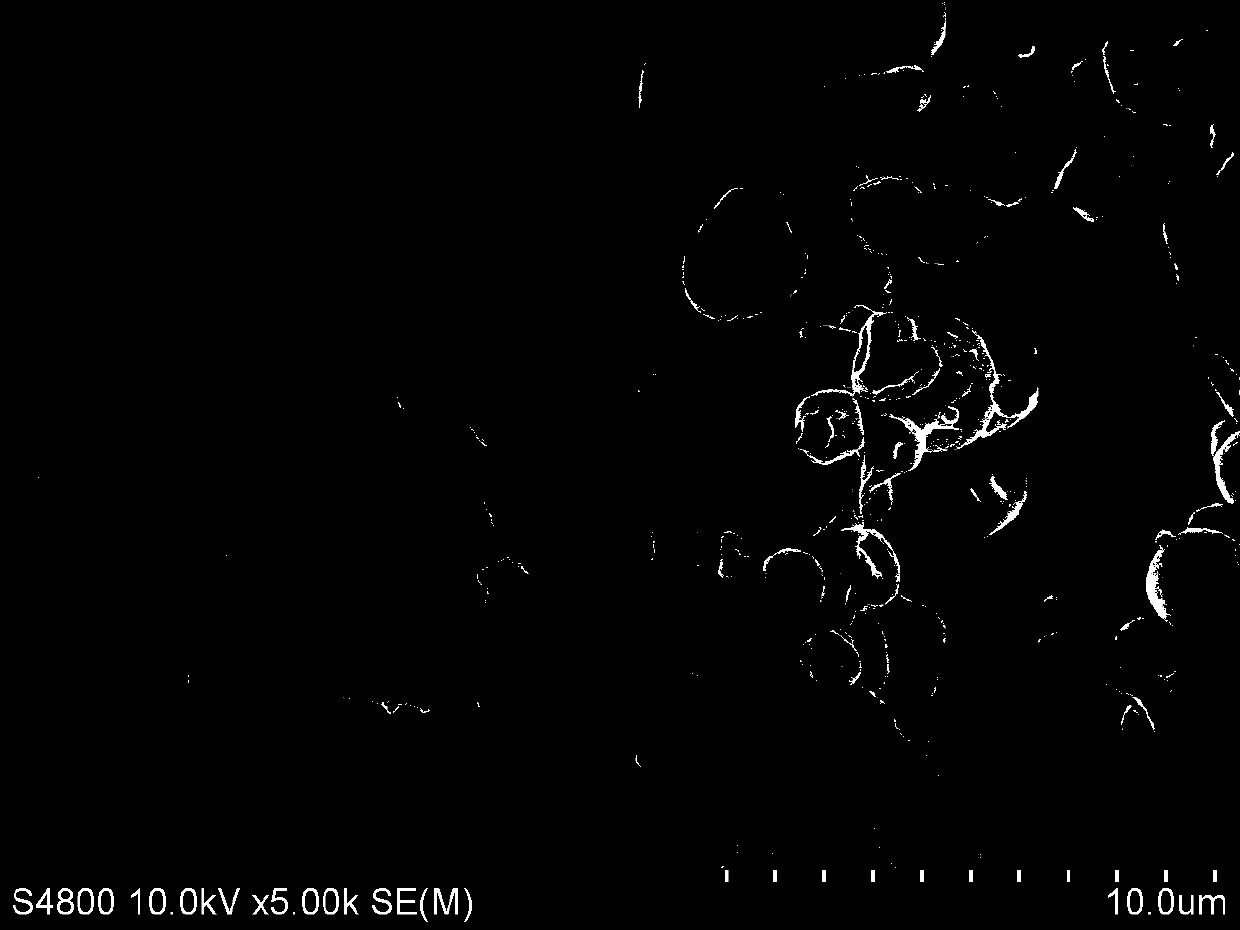

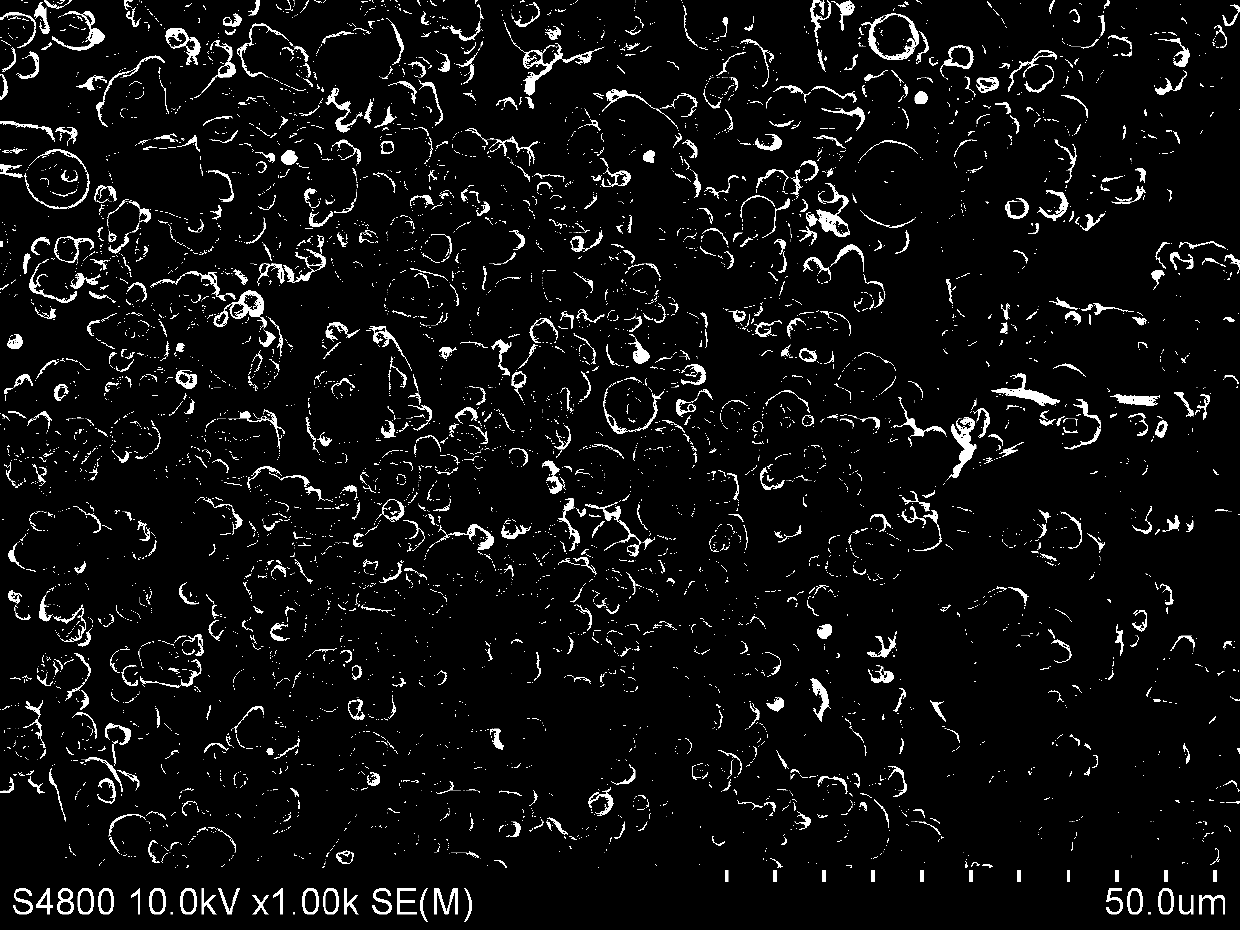

[0041] 3. Refining: After the material liquid is separated, pour out the upper oil phase, discard it, add 5000ml of absolute ethanol to the lower liquid, stir, discard the supernatant, and repeat washing 3 to 5 times. Suction filtration, add 1000 ml of berberine matrix solution to dilute, then spray dry to obtain microspheres of about 1-60 μm. The microspheres...

Embodiment 2

[0043] 1. Preparation of matrix solution: 15 g of sodium alginate, 5 g of carboxymethyl chitosan, and 0.25 g of collagen were respectively dissolved in 1000 ml of water to prepare 3 parts of matrix solution.

[0044] 2. Material mixing: Mix 2500 ml liquid paraffin with 180 ml Tween 80, add sodium alginate, carboxymethyl chitosan and collagen mixed matrix solution to emulsify and stir for 1 hour, add 2% w / w calcium chloride 100 ml Add it dropwise to the mixed material with rapid stirring to carry out cross-linking reaction to prepare microspheres.

[0045] 3. Refining: After the material liquid is separated, pour out the upper oil phase, discard it, add 5000 ml of absolute ethanol to the lower liquid, stir, discard the supernatant, and repeat washing 3 to 5 times. Filter with suction, add 1000 ml of aqueous solution to dilute, and then spray dry to obtain microspheres of about 1-60 μm. The microspheres were further vacuum-dried, aseptically processed, and then sealed and packa...

Embodiment 3

[0047] 1. Preparation of matrix solution: Add 15 g of sodium alginate, 5 g of carboxymethyl chitosan, 0.25 g of collagen and 1 g of berberine into 1000 ml of water and dissolve to prepare 4 parts of matrix solution.

[0048] 2. Material mixing: Mix 2500 ml liquid paraffin dispersant with 180 ml Tween 80 emulsifier, add sodium alginate, carboxymethyl chitosan and collagen mixed matrix solution to emulsify and stir for 1 hour, then add 2% w / w chlorine Calcium chloride 100 ml was added dropwise to the mixed material as a cross-linking agent with rapid stirring to carry out cross-linking reaction to prepare microspheres.

[0049] 3. Refining: After the material liquid is separated, pour out the upper oil phase, discard it, add 5000 ml of absolute ethanol to the lower liquid, stir, discard the supernatant, and repeat washing 3 to 5 times. Suction filtration, add 1000 ml of berberine matrix solution to dilute, then spray dry to obtain microspheres of about 1-60 μm. The microspheres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com