Preparation method and application of copper sulphide/molybdenum sulfide composite

A composite material and molybdenum sulfide technology, applied in catalyst activation/preparation, chemical instruments and methods, hydrogenation hydrocarbon production, etc., can solve the problems of low purity of molybdenum disulfide, harsh reaction conditions, high economic cost, etc., to avoid post-processing The effect of simplification of steps and preparation process and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Under the protection of nitrogen, the ratio of molybdenum, copper and sulfur is 1:A:2.5 (NH 4 ) 6 Mo 7 O 24 ·4H 2 O, Cu(CH 3 COO) 2 With 1,3-two (thioacetic acid-S-n-propyl) imidazolium bromide and 50ml water join successively in volume is 100mL reactor, described (NH 4 ) 6 Mo 7 O 24 ·4H 2 The mass concentration of O was 5 mg / mL, the mixed solution was stirred for 30 minutes, then the reaction kettle was placed in an oven, and the reaction was carried out at 160 ° C for 8 hours. Centrifuge for 5 minutes, wash the powder obtained after centrifugation with methanol and distilled water for 3 times in turn, filter, and then place it in a vacuum drying box with a vacuum degree of -1Mpa and vacuum dry it at 40 ° C for 12 hours. Catalytically active copper sulfide / molybdenum sulfide composites for hydrogen production from water electrolysis.

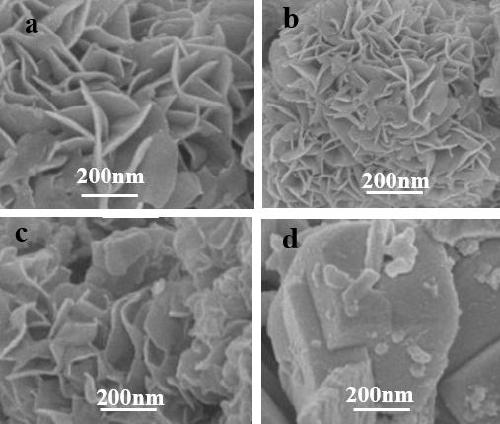

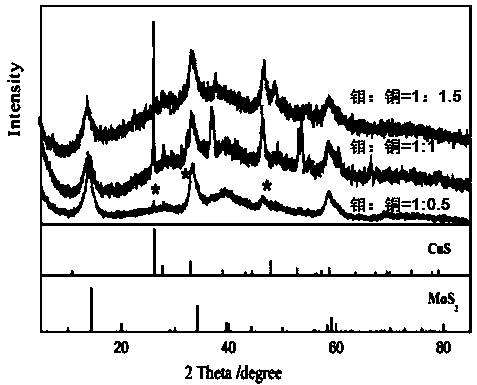

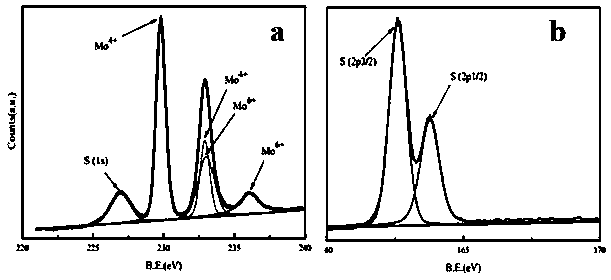

[0030] The copper sulfide / molybdenum sulfide composites prepared with different molybdenum and copper content ratios were su...

Embodiment 2

[0038] Under nitrogen protection, the ratio of molybdenum, copper, and sulfur is 1:1:2.5 (NH 4 ) 6 Mo 7 O 24 ·4H 2 O, Cu(CH 3 COO) 2 With 1,3-two (thioacetic acid-S-n-propyl) imidazolium bromide and 50ml water join successively in volume is 100mL reactor, described (NH 4 ) 6 Mo 7 O 24 ·4H 2 The mass concentration of O was 5 mg / mL, the mixed solution was stirred for 30 minutes, then the reaction kettle was placed in an oven, and the reaction was carried out at 120-200 ° C for 8 hours. centrifugation for 5 min, the powder obtained after centrifugation was washed 3 times with methanol and distilled water in turn, filtered, and then placed in a vacuum drying box with a vacuum degree of -1Mpa and vacuum-dried at 40°C for 12 hours to obtain Copper sulfide / molybdenum sulfide composites with excellent catalytic activity for hydrogen production from water electrolysis.

[0039] The copper sulfide / molybdenum sulfide composites prepared at different reaction temperatures were ...

Embodiment 3

[0045] Under nitrogen protection, the ratio of molybdenum, copper, and sulfur is 1:1:2.5 (NH 4 ) 6 Mo 7 O 24 ·4H 2 O, Cu(CH 3 COO) 2 With 1,3-two (thioacetic acid-S-n-propyl) imidazolium bromide and 50ml water join successively in volume is 100mL reactor, described (NH 4 ) 6 Mo 7 O 24 ·4H 2 The mass concentration of O was 5 mg / mL, the mixed solution was stirred for 30 minutes, then the reaction kettle was placed in an oven, and the reaction was carried out at 160 ° C for 2 to 16 hours, and then the reaction kettle was naturally cooled to room temperature, and the mixture was taken out at 8000 r centrifugation for 5 min, the powder obtained after centrifugation was washed 3 times with methanol and distilled water in turn, filtered, and then placed in a vacuum drying box with a vacuum degree of -1Mpa and vacuum-dried at 40°C for 12 hours to obtain Copper sulfide / molybdenum sulfide composites with excellent catalytic activity for hydrogen production from water electroly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com