Composite powder of metal-metal carbide coated carbon particle and preparation method thereof

A metal carbide and composite powder technology, which is applied in metal processing equipment, carbon fiber, physical treatment, etc., can solve the problems of difficulty and uniform dispersion of carbon, poor wettability of carbon and metal interface, long process flow of metal plating technology, etc. Achieve the effects of excellent and uniform performance, improved high temperature performance, and good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

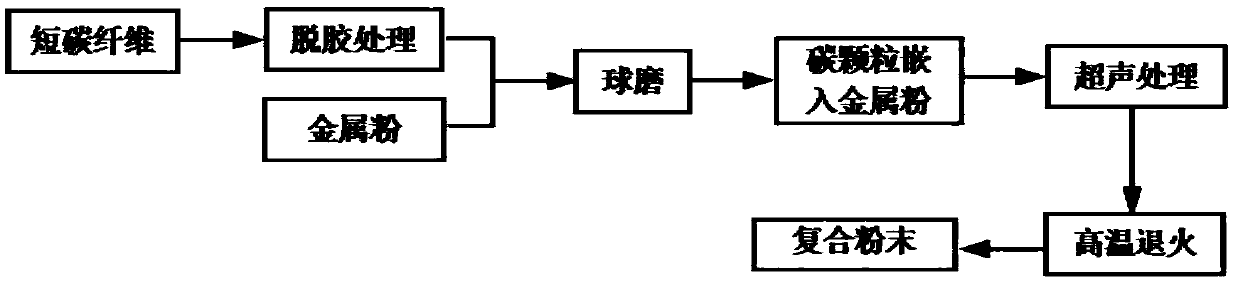

Method used

Image

Examples

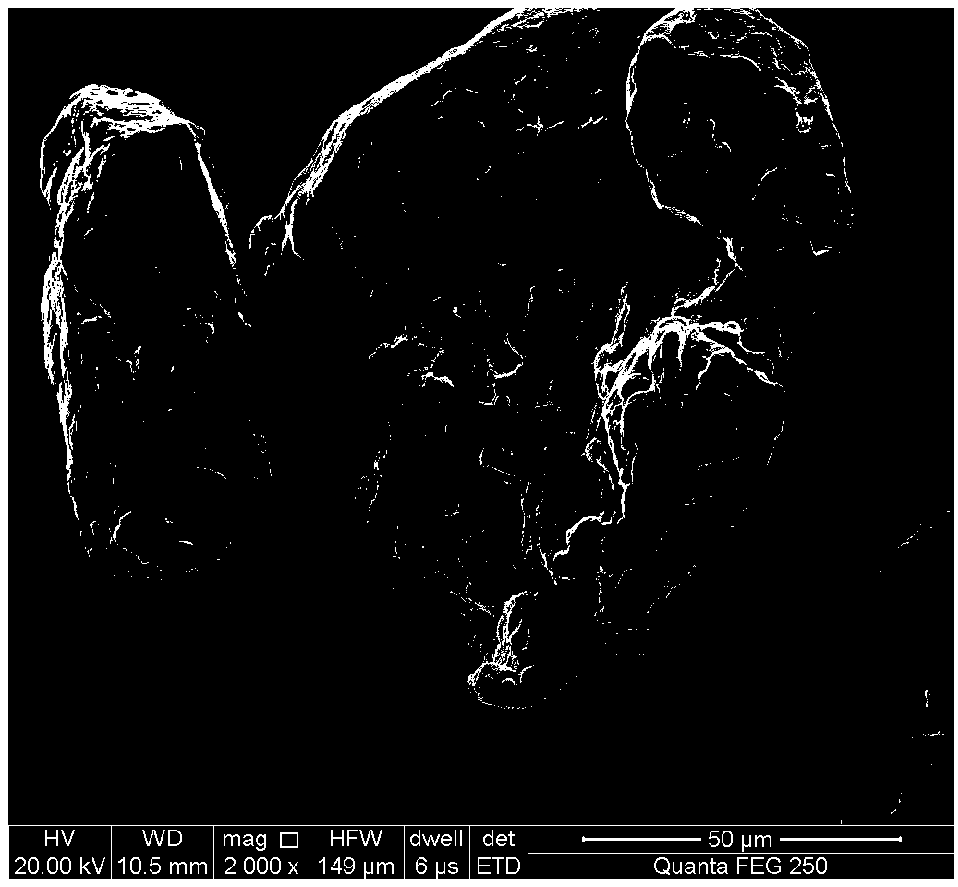

Embodiment 1

[0070] In this embodiment 1, commercially available short carbon fibers that have been degummed at 700°C for 60 minutes and reduced iron powder with a particle size of 120 μm are used as ball milling raw materials. 6μm, length 2mm, the two are added to the ball milling equipment for high-energy ball milling, the speed is 250r / min, the ball milling time is 6h, the ball-to-material ratio is 6:1, the ball milling balls are stainless steel balls and hard alloy balls, the ball diameter 3mm~10mm (mass ratio of ball milling ball diameter 3mm, 4mm, 5mm, 6mm, 7mm, 8mm, 9mm is 4:8:11:20:12:8:6:1); mixed powder after ball milling; Carry out separation process to mixed powder; The step of separation process is:

[0071]Step 1, place the mixed powder on an ultra-fine powder separation ultrasonic rotary vibrating sieve for sieving treatment, the minimum mesh size of the sieve is 2000 mesh, take the sieve and mix it with alcohol, add ultrasonic treatment for 120min (ultrasonic frequency is 2...

Embodiment 2

[0075] In Example 2, commercially available short carbon fibers that have been degummed at 750°C for 60 minutes and chromium powder with a particle size of 100 μm are used as raw materials for ball milling. The volume percentage of carbon fibers is 5%, and the volume percentage of chromium powder is 95%. , length 2mm, the two are added to the ball milling equipment for high-energy ball milling, the rotating speed is 280r / min, the ball milling time is 7h, the ball-to-material ratio is 6:1, and the mixed powder is obtained after the ball milling is completed; the mixed powder is separated; The steps of the separation process are:

[0076] Step 1, put the mixed powder on the superfine powder separation ultrasonic rotary vibrating sieve for sieving treatment, the minimum mesh size of the sieve is 2000 mesh, take the sieve and mix it with alcohol, add ultrasonic treatment for 90min (ultrasonic frequency is 25KHz), maintain The temperature of the solution is room temperature, and th...

Embodiment 3

[0079] In Example 3, commercially available short carbon fibers that have been degummed at 800°C for 60 minutes and titanium powder with a particle size of 50 μm are used as raw materials for ball milling. The volume percentage of short carbon fibers is 10%, and the volume percentage of titanium powder is 90%. The diameter of the short carbon fibers is 6μm, length 2mm, the two are added to the ball milling equipment for high-energy ball milling, the speed is 320r / min, the ball milling time is 8h, the ball-to-material ratio is 6:1, and the mixed powder is obtained after the ball milling; the mixed powder is separated. ;The steps of separation processing are:

[0080] Step 1, place the mixed powder on an ultra-fine powder separation ultrasonic rotary vibrating sieve for sieving treatment, the minimum mesh size of the sieve is 2000 mesh, take the sieve and mix it with alcohol, add ultrasonic treatment for 40min (ultrasonic frequency is 25KHz), maintain The temperature of the solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com