Porous carbon material with high specific surface area prepared by virtue of fungal pretreatment as well as method and application thereof

A high specific surface area, porous carbon technology, applied in the field of porous carbon materials, can solve the problems of complex process conditions, secondary pollution and high cost, and achieve the effects of simple process, no secondary pollution and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

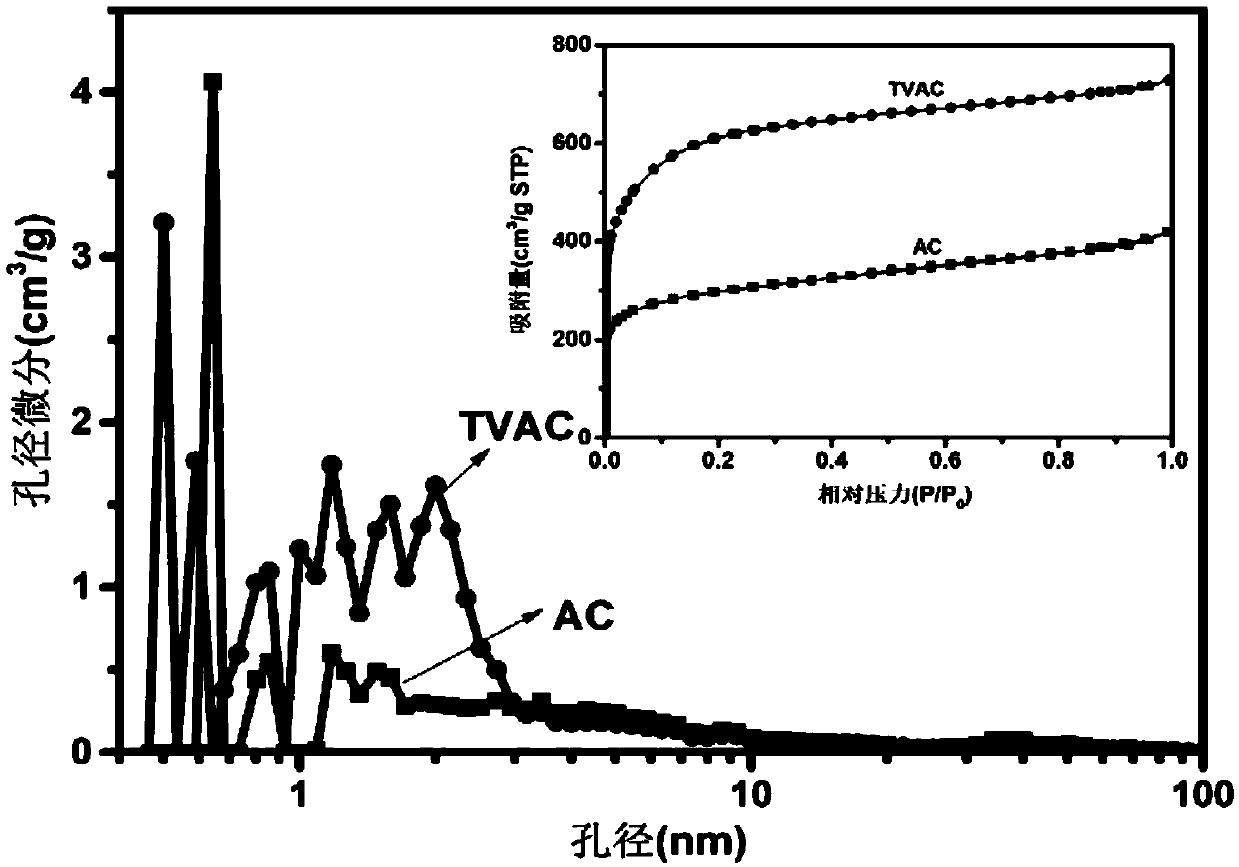

Embodiment 1

[0036] A method for preparing microporous high specific surface area porous carbon by treating cellulose degrading bacteria, comprising the following steps:

[0037] (1) Dilute the freeze-dried powder of Trichodermaviride 10000 times with sterilized deionized water, draw 0.2mL of the dissolved dry powder bacteria liquid with a pipette gun and inoculate it on the solid potato medium, spread it evenly, and put it into the culture medium Cultivate in the box at 30°C for 6 days; then drop sterilized deionized water into the culture plate, stir gently with an inoculation needle, and filter with gauze to obtain T.viride spore suspension, which is sealed and stored in a refrigerator at 6°C for future ;

[0038](2) cleaning lotus leaf biomass, drying at 90°C, and cutting into 0.5-1.5cm fragments to obtain pretreated raw materials;

[0039] (3) Take 200g of peeled potatoes, wash, cut into small pieces, add 1L of deionized water and boil for 30min to obtain the filtrate; make up the fi...

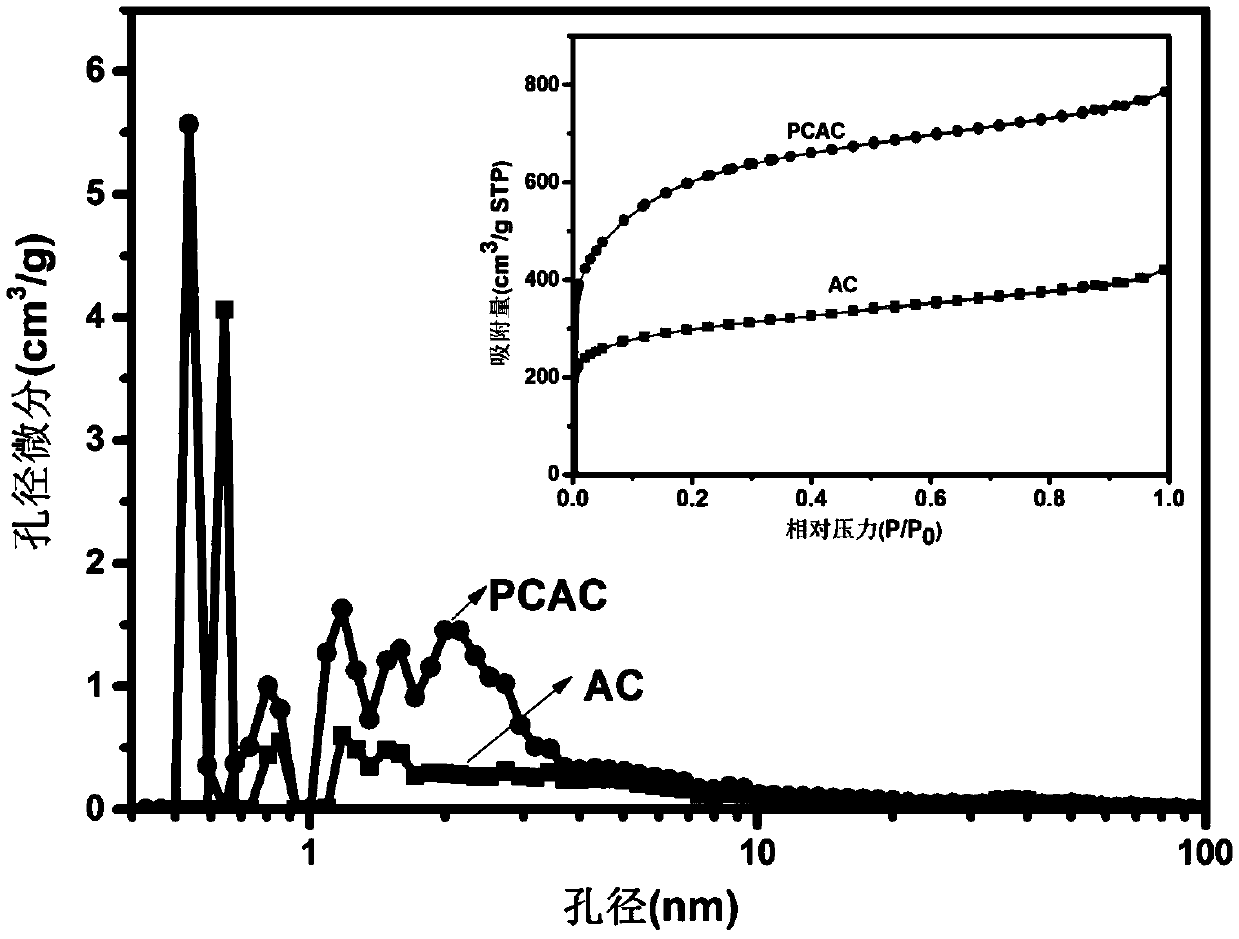

Embodiment 2

[0045] The method for preparing mesoporous high specific surface area porous carbon by processing lignin degrading bacteria comprises the following steps:

[0046] (1) Dilute the freeze-dried powder of Phanerochaetechrysosporium chrysosporium 10000 times with sterilized deionized water, draw 0.2mL of the dissolved dry powder bacteria liquid with a pipette gun and inoculate it on the PDA medium, spread it evenly, and put it in Cultivate in an incubator at 30°C for 6 days; then drop sterilized deionized water into the culture plate, gently stir it with an inoculation needle, and filter it with gauze to obtain a spore suspension of Phanerochaete chrysosporium, that is, a suspension of P. liquid, sealed and stored in a refrigerator at 6°C, and set aside;

[0047] (2) cleaning lotus leaf biomass, drying at 90°C, and cutting into 0.5-1.5cm fragments to obtain pretreated raw materials;

[0048] (3) Take 200g of peeled potatoes, wash, cut into small pieces, add 1L of deionized water ...

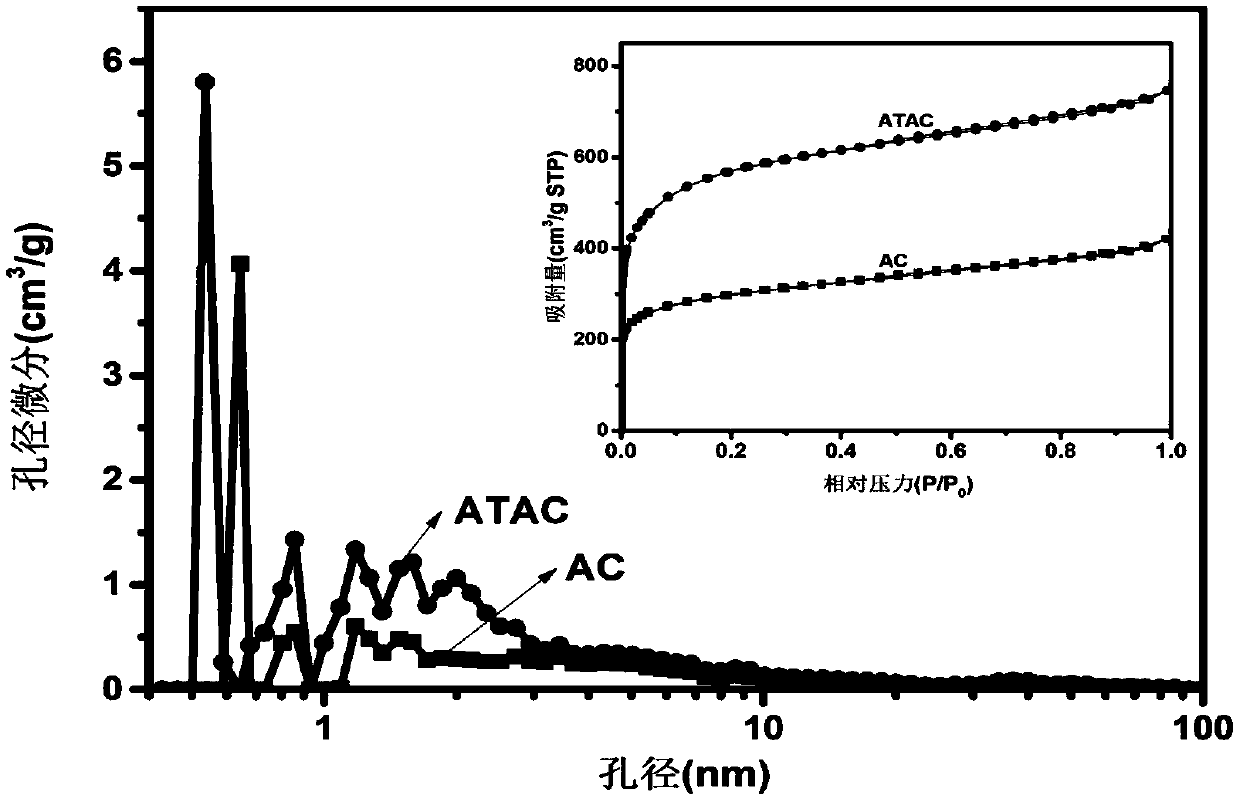

Embodiment 3

[0054] A method for preparing a micro-mesoporous high specific surface area porous carbon material by treating hemicellulose degrading bacteria, comprising the following steps:

[0055] (1) Dilute the freeze-dried powder of Aspergillus tubingensis 10000 times with sterilized deionized water, draw 0.4mL of the dissolved dry powder bacteria liquid with a pipette gun and inoculate it on the Chapeau agar medium, spread it evenly, and put it into the culture medium Cultivate in the box at 30°C for 6 days, then drop sterilized deionized water into the cultured plate, gently stir with an inoculation needle, and filter with gauze to obtain A. tubingensis spore suspension, which is sealed and stored in a 6°C refrigerator for later ;

[0056] (2) cleaning lotus leaf biomass, drying at 90°C, and cutting into 0.5-1.5cm fragments to obtain pretreated raw materials;

[0057] (3) Take 30g of Cha's liquid medium and add it to 1L of deionized water, dissolve, sterilize, cool to room temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Micropore specific surface area | aaaaa | aaaaa |

| Mesopore specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com