Method of catalytically hydrating alkylene oxide to produce ethylene glycol

A technology for catalyzing water and alkylene oxide with alkylene oxide, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc. It can solve the difficulties of separation and purification of functional monomers, affect the performance of final polymers, and harsh operating conditions and other problems, to achieve the effect of increasing the glass transition temperature, good heat resistance, and high swelling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

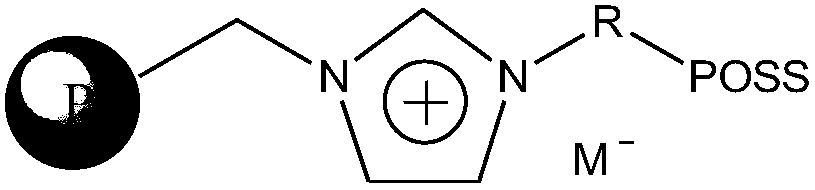

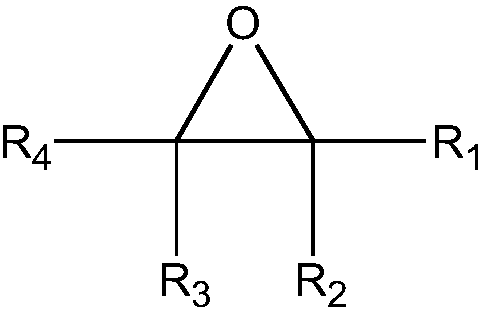

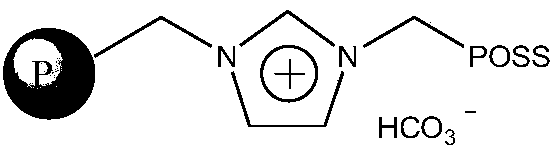

Method used

Image

Examples

Embodiment 1

[0035] [Example 1] Preparation of ion exchange resin catalyst

[0036] Add 47.0 g of styrene, 2.3 g of divinylbenzene, 30 g of polystyrene and 1.6 g of benzoyl peroxide initiator into a 500 ml three-necked flask, stir and react at 60°C for 1.5 hours; then add 0.6 g of multilayer Graphene, continue to stir for 1 hour for pre-polymerization. Add 260 ml of deionized water solution in which 2.0 g of gelatin has been dissolved. Adjust the stirring speed while gradually raising the temperature to 80°C and reacting for 5 hours; then raising the temperature to 90°C and reacting for 5 hours, and finally raising the temperature to 98°C and reacting for 8 hours. After the reaction, the upper liquid was poured out, washed with hot water at 85°C, then washed with cold water, then filtered, dried in an oven at 80°C, sieved, and collected composite macropores with a particle size in the range of 0.35~0.60mm Microsphere A1.

[0037] Chloromethylation of composite macroporous microspheres: In a ...

Embodiment 2

[0042] [Example 2] Preparation of ion exchange resin catalyst

[0043] Add the monomer mixture solution (60.0 g styrene, 1.0 g divinylbenzene, 60 g polystyrene, 1.6 g multilayer graphene and 1.0 g benzoyl peroxide) containing the initiator to a 500 ml three-necked flask. The solution was stirred and reacted at 70°C for 0.5 hours), started the stirrer, added a mixed solution of 200ml deionized water and 4g polyvinyl alcohol, heated to 85°C, reacted for 3 hours, then heated to 90°C, reacted for 9 hours, Finally, the temperature was raised to 100°C and reacted for 10 hours. After the reaction, the upper liquid was poured out, washed with hot water at 85°C, then washed with cold water, then filtered, dried in an oven at 80°C, sieved, and collected composite macropores with a particle size in the range of 0.35~0.60 mm Microsphere B1.

[0044] Chloromethylation of composite microspheres: In a 500 ml three-necked flask, add 50 grams of composite microspheres B1 and 200 ml of chloroethyl...

Embodiment 3

[0049] [Example 3] Preparation of ion exchange resin catalyst

[0050] Add the monomer mixture solution containing initiator (42.5 g styrene, 2.5 g divinylbenzene, 10 g polystyrene, 0.1 g multilayer graphene and 2.0 g benzoyl peroxide) into a 500 ml three-necked flask. The solution was first stirred and reacted at 70°C for 1.5 hours), added 200ml of deionized water and 4g of polyvinyl alcohol mixed solution, heated to 85°C, reacted for 3 hours, then heated to 90°C, reacted for 9 hours, and finally heated to 100 ℃, react for 10 hours. After the reaction, the upper liquid was poured out, washed with hot water at 85°C, then washed with cold water, then filtered, dried in an oven at 80°C, sieved, and collected composite macropores with a particle size in the range of 0.35~0.60 mm Microsphere C1.

[0051] Chloromethylation of composite microspheres: In a 250 ml three-necked flask, add 20 grams of composite microspheres C1 and 100 ml of 1,4-dichloromethoxybutane, let stand at room temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com