Oil-soluble chitosan derivative and preparation method and application thereof

A chitosan derivative and oil-soluble technology is applied in the field of oil-soluble chitosan derivatives and its preparation, which can solve the problems of reducing the adsorption of metal ions, the difficulty of chitosan molecules having both oil-solubility and adsorption properties, and the like. The effect of improving solubility, good solubility and dispersibility, and good maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

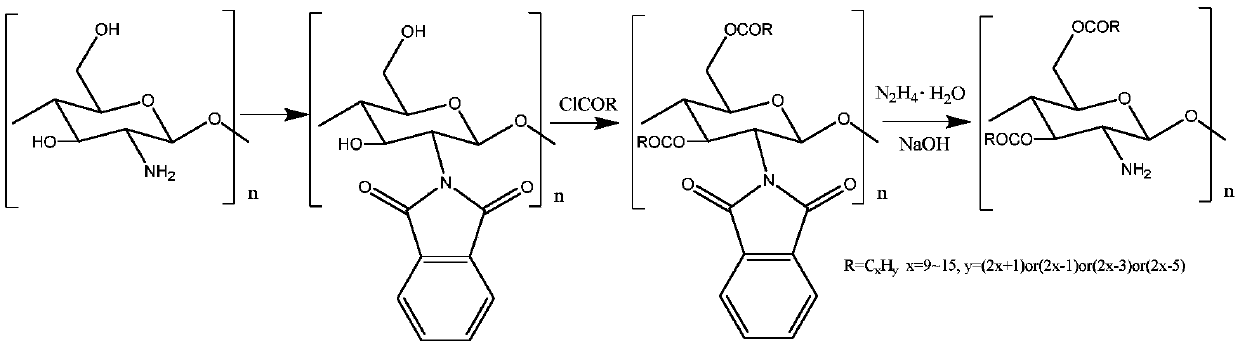

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of O-lauric acid acylated chitosan. Add chitosan to a certain amount of N,N-dimethylformamide with a volume ratio of 10% water, record the quality of chitosan as 1 part, add 3 parts of phthalic acid to react, and make the reaction at 100 °C under normal pressure React for 5 hours, filter and wash after the reaction to obtain the intermediate product; then, add the intermediate product and 1 part of lauric acid chloride to the isopropanol solvent for reaction, and stir the reaction at 70°C for 2 hours under normal pressure; then the amount of the substance used is Hydrazine monohydrate of 1.5 times of phthalic acid and concentration are 1mol / L sodium hydroxide aqueous solution (being 10 times of chitosan in terms of mass fractions) to remove phthaloyl group, and product is used after freeze-drying O-lauric acid acylated chitosan was obtained after washing with distilled water and freeze-drying again.

Embodiment 2

[0028] A preparation method of O-myristic acid acylated chitosan. Add chitosan to a certain amount of N,N-dimethylformamide with a volume ratio of 20% water, record the mass of chitosan as 1 part, add 3 parts of phthalic acid to react, and make it under normal pressure at 110 °C React for 4 hours, filter and wash the intermediate product after the reaction is completed; then, add the intermediate product and 3 parts of myristic acid chloride into isopropanol solvent for reaction, stir and react for 5 hours at 60°C under normal pressure; then use the amount of substance Hydrazine monohydrate 2 times that of phthalic acid and a concentration of 1mol / L sodium hydroxide aqueous solution (8 times that of chitosan in parts by mass) remove phthaloyl groups, and the product is freeze-dried After washing with distilled water and freeze-drying again, O-myristic acid acylated chitosan was obtained.

Embodiment 3

[0030]A preparation method of O-palmitic acid acylated chitosan. Add chitosan to a certain amount of N,N-dimethylformamide with a water volume ratio of 15%, record the quality of chitosan as 1 part, add 3 parts of phthalic acid to react, and make the reaction at 150 ° C under normal pressure React for 2 hours, filter and wash after the reaction to obtain the intermediate product; then, add the intermediate product and 2 parts of palmitic acid chloride to the isopropanol solvent for reaction, stir and react at 80°C under normal pressure for 1 hour; subsequently, the amount of the substance used is The hydrazine monohydrate of 1 time of phthalic acid and the concentration are 1mol / L sodium hydroxide aqueous solution (being 1 time of chitosan in terms of mass parts) to remove phthaloyl group, and the product is through after freeze-drying After washing with distilled water and freeze-drying again, O-palmitic acid acylated chitosan was obtained.

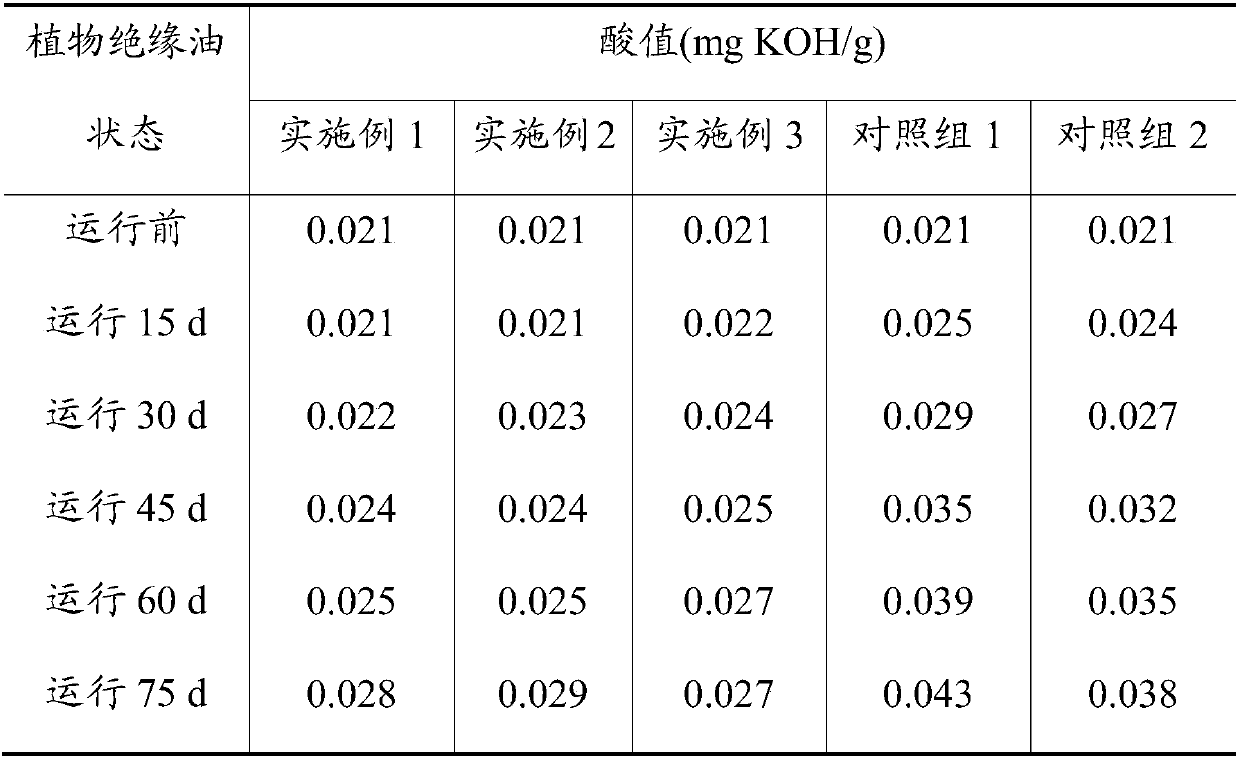

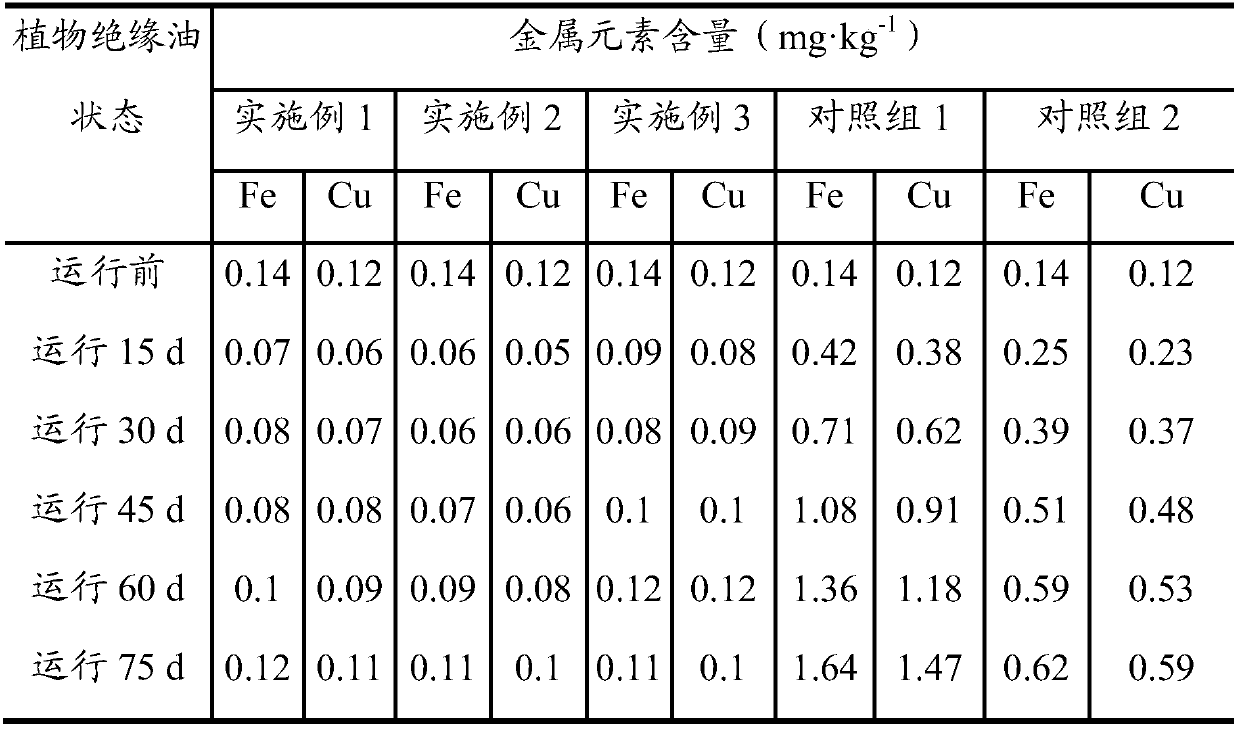

[0031] Get the prepared O-acylat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com