Method for preparing hybrid integrated fiber optic gyroscope optical chip

A technology of optical chips and fiber optic gyroscopes, which is applied in gyroscope/steering sensing equipment, Sagnac effect gyroscopes, measuring devices, etc., can solve the problem of poor integration of semiconductor photonic devices, limitations of manufacturing process and semiconductor process compatibility Problems such as integration and miniaturization of the fiber optic gyroscope, poor system environmental adaptability and reliability, etc., to meet the requirements of reciprocity, low cost and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] In addition, the present invention also provides a preparation method for preparing the above-mentioned hybrid integrated fiber optic gyro optical chip, the method comprising the following steps:

[0065] Step 1: Design and cut out the substrate 1, the substrate of the lithium niobate Y-branch phase modulator 4 and the silicon substrate of the 3dB coupling 3 according to the above-mentioned chip size;

[0066] Step 2: Deposit a layer of SiO2 thin film on the silicon substrate by PECVD and ICP etching as a buffer layer; grow a germanium-doped SiO2 thin film on the SiO2 thin film, the thickness of which is the thickness of the waveguide core layer; Engraving and etching process forms a core layer waveguide pattern on the SiO2:Ge film; then deposits a layer of SiO2 film on it, and anneals to obtain a 3dB coupler;

[0067] Step 3: According to the graphic design of the above-mentioned lithium niobate Y-branch phase modulator 4, the Y-branch waveguide is fabricated on the li...

Embodiment 1

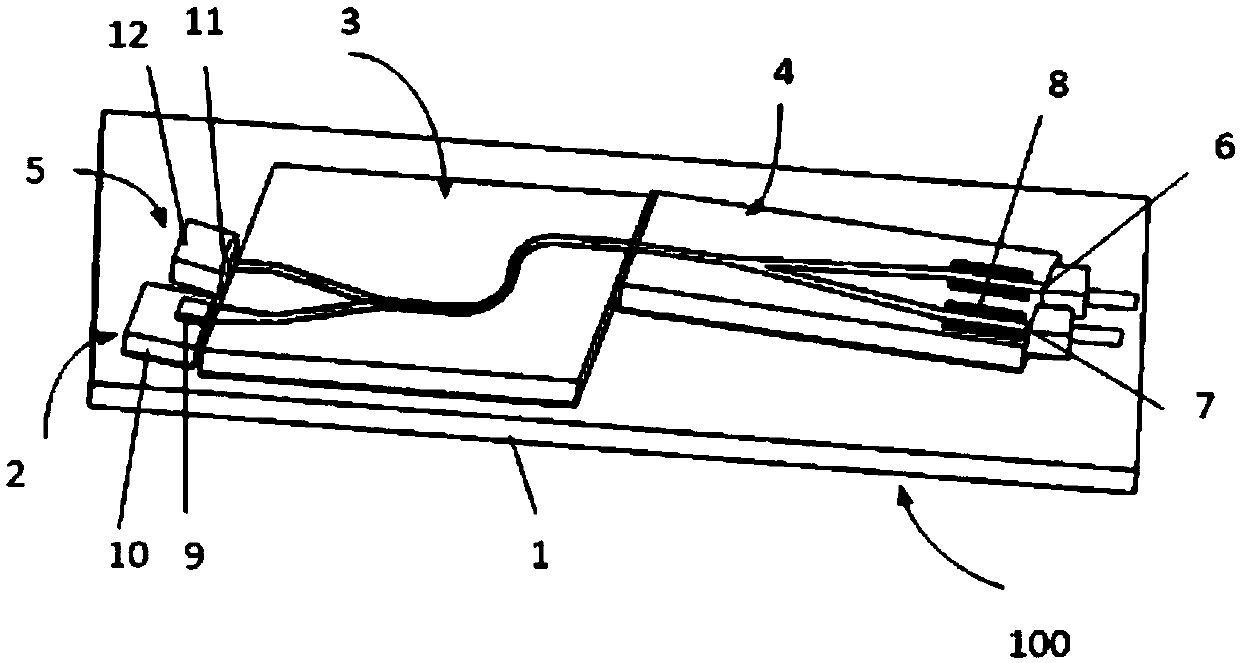

[0077] This example refers to Figure 1-3 , the hybrid integrated fiber optic gyroscope optical chip 100 of the present invention has a substrate 1, a light source 2, a 3dB coupler 3, a lithium niobate Y branch phase modulator 4, and a signal detector 5; the light source 2, the 3dB coupler 3, niobate The lithium Y-branch phase modulator 4 and the photodetector 5 are mixed and integrated on the substrate 1;

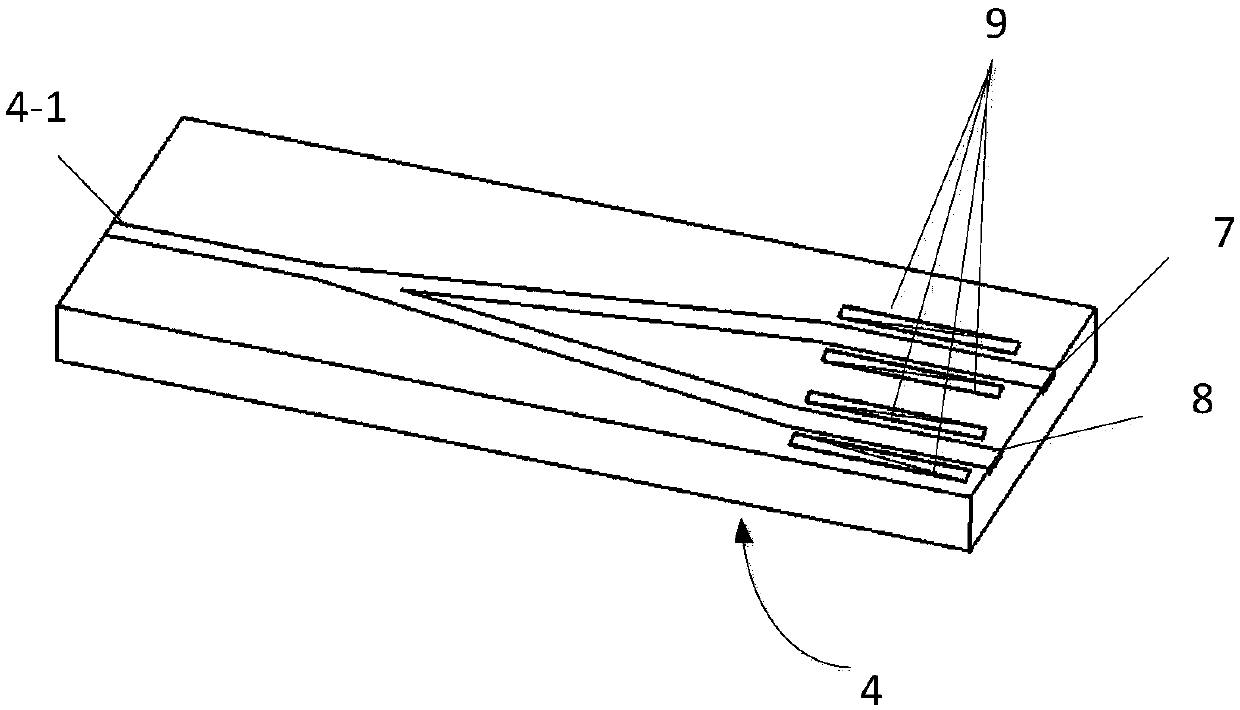

[0078] The lithium niobate Y-branch phase modulator 4 is a lithium niobate-based proton exchange waveguide. Taking the transmission wavelength of 1310nm as an example, the width of the single-mode waveguide is usually 5.5-6 μm;

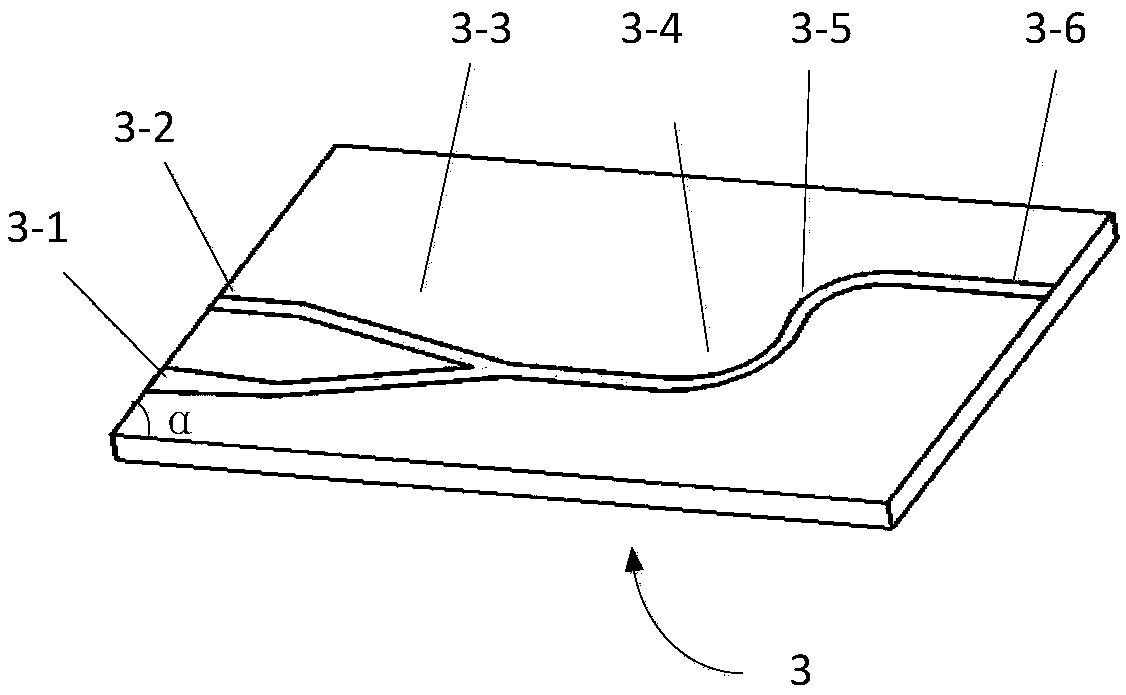

[0079] Silicon-based 3dB coupler 3 is based on the mature silicon-based silicon dioxide optical waveguide manufacturing technology, usually using ion-enhanced chemical vapor deposition PECVD technology for SiO2 lower cladding and core film growth, and then using photolithography and inductively coupled plasma etching ICP technology forms a silicon-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com