Method for preparing nickel-cobalt-phosphorus integrated electrode material having core-shell structure

A core-shell structure and electrode material technology, applied in the field of materials science, can solve the problems of unsatisfactory cycle performance of nickel-cobalt phosphide and limit the application of nickel-cobalt phosphide, so as to reduce electron transfer resistance, improve cycle performance, and increase utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

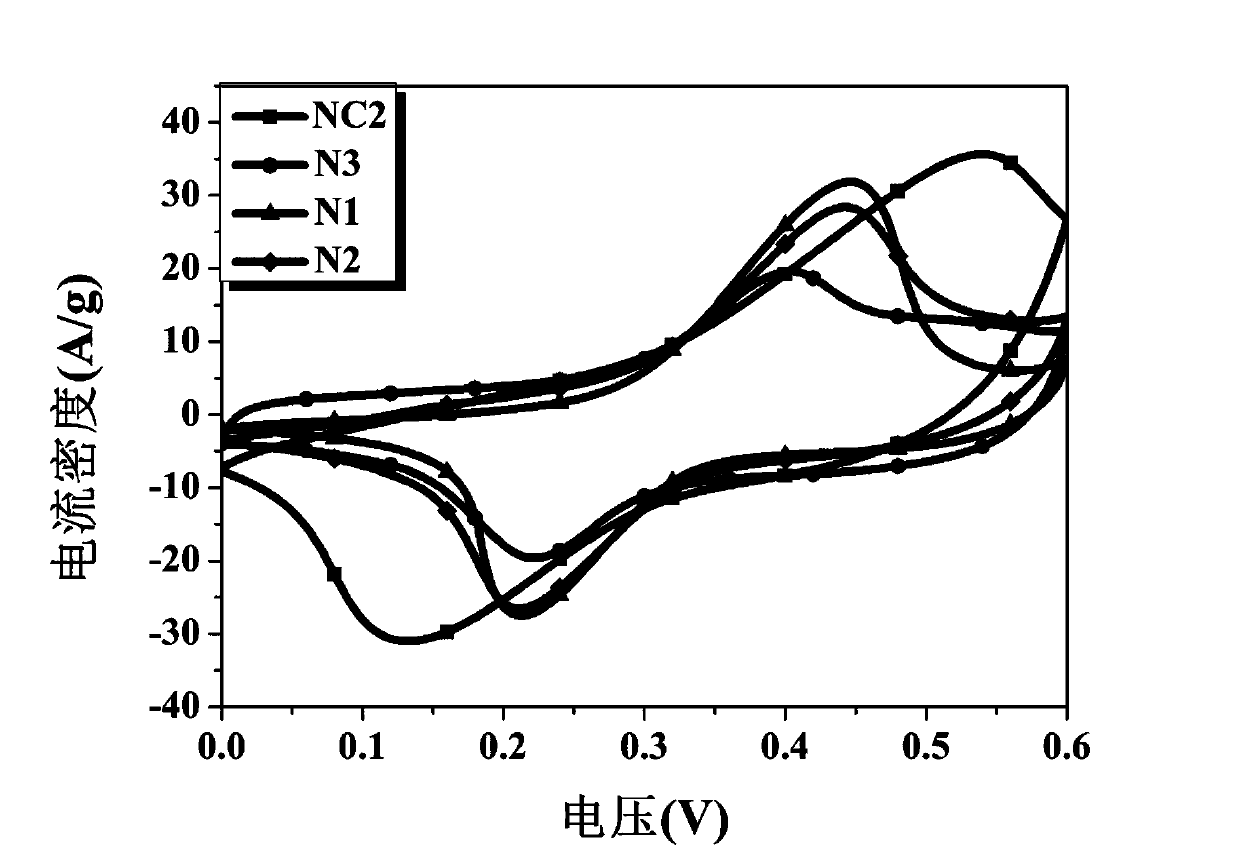

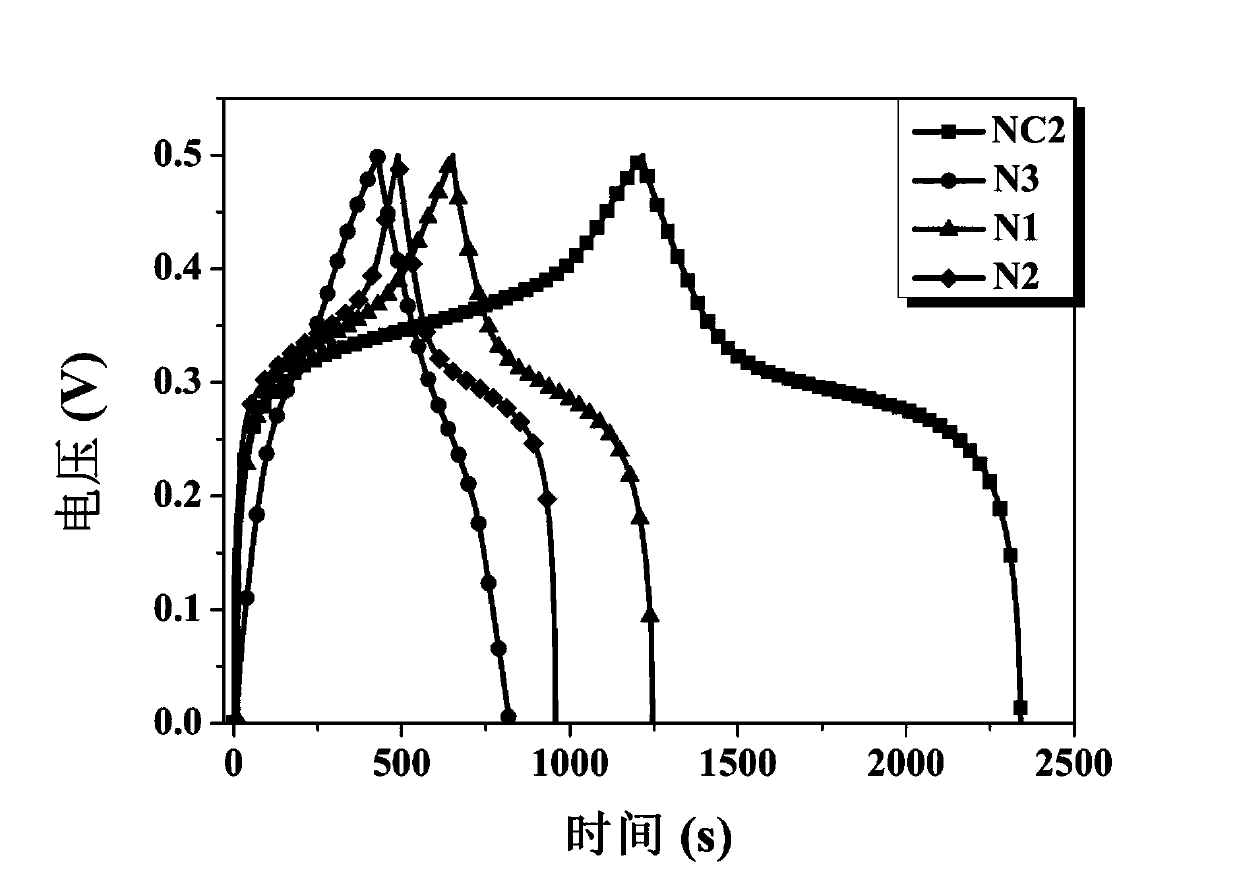

Embodiment 1

[0027] (1) Take a carbon cloth with a size of 1 cm × 2 cm and put it in dilute hydrochloric acid, acetone, ethanol and deionized water for ultrasonic cleaning, and finally dry it in a vacuum oven at 60 ° C for 3 h for later use. The concentration of dilute hydrochloric acid is 3M.

[0028] (2) Get 1 mmol of nickel nitrate hexahydrate, 1 mmol of cobalt nitrate hexahydrate, and 3 mmol of urea, add together in the reactor that 40 ml of deionized water and 10 ml of ethanol mixed solution are housed, magnetically stir until A transparent pink solution was formed, and the carbon cloth was immersed in the solution; the reaction kettle was sealed, and the temperature was raised to 120° C. for 5 hours. After cooling to room temperature, the carbon cloth was taken out, placed in deionized water and absolute ethanol for ultrasonic cleaning several times, and dried in a vacuum oven at 60°C for 12 hours to obtain a carbon cloth with NiCo precursor nanowire array matrix grown on the surface...

Embodiment 2

[0033] (1) Take a carbon cloth with a size of 1 cm × 2 cm and put it in dilute hydrochloric acid, acetone, ethanol and deionized water for ultrasonic cleaning, and finally dry it in a vacuum oven at 60 ° C for 3 h for later use. The concentration of dilute hydrochloric acid is 3M.

[0034] (2) Get 2 millimoles of nickel nitrate hexahydrate, 2 millimoles of cobalt nitrate hexahydrate, and 4 millimoles of urea and add together in the reactor that the mixed solution of 20ml deionized water and 5ml ethanol is housed, and magnetically stir until A transparent pink solution was formed, and the carbon cloth was immersed in the solution; the reaction kettle was sealed, and the temperature was raised to 120° C. for 5 hours. After cooling to room temperature, the carbon cloth was taken out, placed in deionized water and absolute ethanol for ultrasonic cleaning several times, and dried in a vacuum oven at 60°C for 12 hours to obtain a carbon cloth with NiCo precursor nanowire array matri...

Embodiment 3

[0039] (1) Take a carbon cloth with a size of 1 cm × 2 cm and put it in dilute hydrochloric acid, acetone, ethanol and deionized water for ultrasonic cleaning, and finally dry it in a vacuum oven at 60 ° C for 3 h for later use. The concentration of dilute hydrochloric acid is 3M.

[0040] (2) Take 3 millimoles of nickel nitrate hexahydrate, 3 millimoles of cobalt nitrate hexahydrate, and 4.5 millimoles of urea and add them together to a reaction kettle equipped with a mixture of 60 ml of deionized water and 15 ml of ethanol, and stir magnetically until the mixture is formed. Transparent pink solution, immerse the carbon cloth in the solution; seal the reaction kettle, heat up to 120°C and react for 5 hours. After cooling to room temperature, the carbon cloth was taken out, placed in deionized water and absolute ethanol for ultrasonic cleaning several times, and dried in a vacuum oven at 60°C for 12 hours to obtain a carbon cloth with NiCo precursor nanowire array matrix grown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com