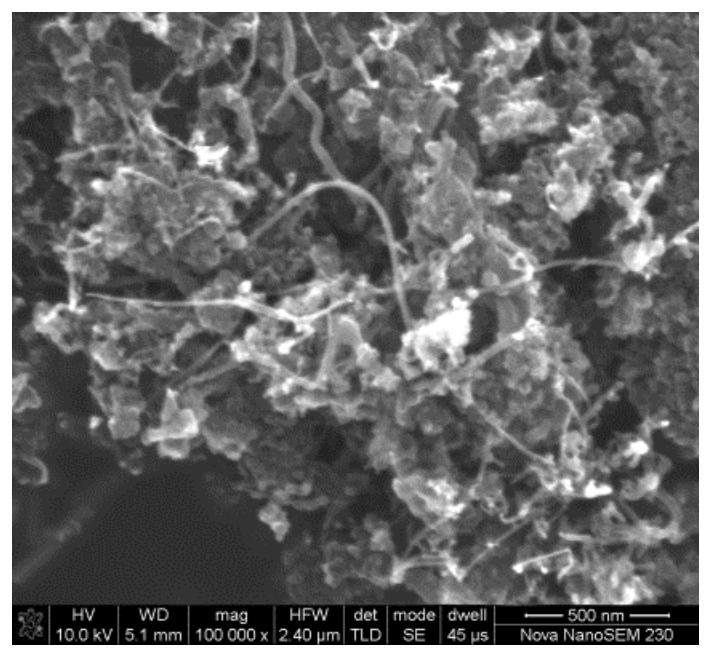

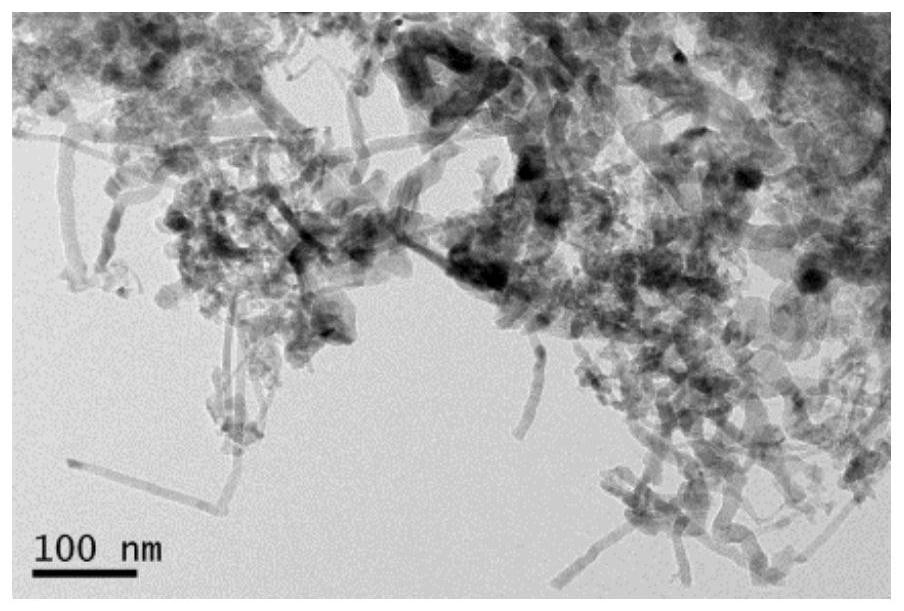

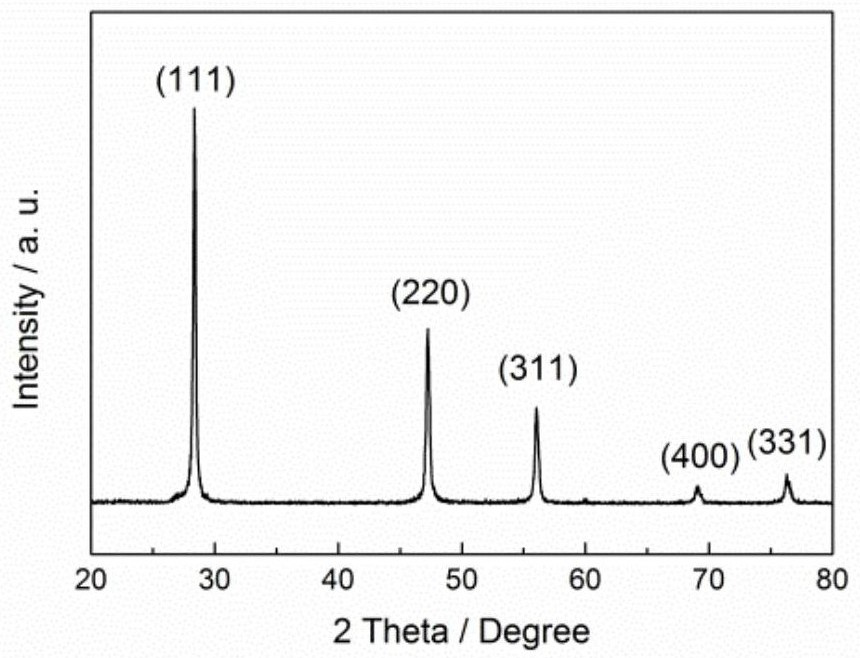

A kind of carbon nanotube filled silicon/hollow carbon composite negative electrode material and preparation method thereof

A technology of carbon nanotubes and anode materials, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of limiting the uniformity of composite materials, low compaction density electron transport paths of composite materials, carbon Problems such as poor dispersion of nanotubes, to achieve the effect of being suitable for large-scale production, easy for large-scale production, and improving rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) Take 2g of silicon particles with a particle size of 10nm and disperse them in 100ml of an aqueous solution in which 0.002g of cetyltrimethylammonium bromide is dissolved, and after ultrasonic dispersion is uniform, stir for 10min to obtain surface-modified silicon particles;

[0055] (2) Take the surface-modified silicon particles obtained in step 1, add 1 g of polypropylene and 0.01 g of cobalt tetroxide powder, and mix them into a uniform precursor by mechanical ball milling;

[0056] (3) Place the homogeneous precursor described in the above step in a tube furnace, feed nitrogen gas, evacuate, keep the pressure in the tube at 1000 Pa, and perform heat treatment at a temperature of 800°C and a holding time of 2 hours;

[0057] (4) Dissolve 0.4g of glucose in 20ml of ethanol and 30ml of water, then add the silicon / carbon nanotubes obtained in step 3 into the above solution, stir evenly, and place it in a drying oven at 80°C for 24 hours. Obtain glucose-coated sili...

Embodiment 2

[0062] (1) Get 2g of silicon particles with a particle size of 300nm and disperse them in 100ml of alcohol solution in which 1g of cetyltrimethylammonium bromide is dissolved. After ultrasonic dispersion, stir for 5h to obtain surface-modified silicon particles;

[0063] (2) Take the surface-modified silicon particles obtained in step 1, add 10 g of polypropylene and 0.4 g of ferrosilicon powder, and mechanically mix to form a uniform precursor;

[0064] (3) Put the homogeneous precursor obtained in step 2 in a tube furnace, pass in argon, evacuate, keep the pressure in the tube at 600 Pa, and perform heat treatment. The heat treatment system is 10°C / min to 1200°C, and the holding time 0.5h;

[0065] (4) Dissolve 10g of sucrose in 20ml of methanol and 30ml of water, then add the silicon / carbon nanotubes obtained in step 3 into the above solution, stir evenly, place it in a drying oven at 150°C for 10h, and grind After obtaining the silicon / carbon nanotube composite sample coa...

Embodiment 3

[0070] (1) Take 2g of silicon particles with a particle size of 50nm and disperse them in 100ml of acetone solution in which 0.4g of cetyltrimethylammonium bromide is dissolved. After the ultrasonic dispersion is uniform, stir for 2h to obtain surface-modified silicon particles. ;

[0071] (2) Take the surface-modified silicon particles obtained in step 1, add 4 g of polypropylene and 0.1 g of nickel oxalate hydrate, and mechanically mix to form a uniform precursor;

[0072] (3) Put the homogeneous precursor obtained in step 2 in a tube furnace, pass in argon gas, evacuate, keep the pressure in the tube at 1200 Pa, and perform heat treatment. The heat treatment system is 5°C / min to 800°C, and the holding time for 2h;

[0073] (4) Dissolve 2g of starch in 20ml of ethanol and 30ml of water, then add the silicon / carbon nanotubes obtained in step 3 into the above solution, stir evenly, place it in a drying oven at 120°C for 15 hours, and grind Obtain starch-coated silicon / carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com